The global high-quality phosphate resources are continuously developed and utilized, and their reserves are decreasing year by year, especially in areas with low ore grades. The proportion of medium and low-grade phosphate resources is increasing. In the face of such changes in the proportion of resources, studying how to mine and utilize medium and low-grade phosphate is the main solution. Phosphate ore dressing technology is the key to improving the efficiency of mineral resource utilization, which directly affects the recovery rate, grade and environment of phosphate resources. The following mainly describes the main phosphate ore dressing technology and discusses the development trend of various dressing technologies.

1. Scrubbing and desludging technology

This process mainly removes fine mud and impurities on the surface of phosphate ore through physical friction and water flow, thereby improving the purity of phosphate ore. The process mainly includes crushing, screening, scrubbing and desludging.

Advantages: The process principle is simple, the operation is convenient, and this process is not easy to be corroded by chemical agents and has environmental protection characteristics.

Disadvantages: This process is not suitable for processing ores with a relatively high concentrate enrichment ratio. The concentrate grade obtained is low, and the content of phosphate minerals in the tailings is relatively high.

2. Flotation process

Flotation process is a commonly used technology for phosphate ore dressing. The hydrophilicity and lipophilicity of the mineral surface are adjusted by the dressing agent. After the mineral surface changes, the base of the foam changes, thereby achieving the separation of minerals. The flotation process can be used to treat phosphate ore with complex mineral structure, which is an important means to improve the recovery rate and grade of phosphate ore.

① Positive flotation process: used to treat siliceous phosphate ore with more silicon minerals and low magnesium oxide content. This process suppresses gangue minerals such as quartz and feldspar, and the phosphate minerals are combined with bubbles to float out preferentially.

② Reverse flotation process: used to treat calcareous phosphate rock containing minerals such as dolomite and gypsum. This process suppresses the flotation of phosphate minerals and preferentially floats out gangue minerals, thereby improving the grade of phosphate ore.

③ Direct and reverse flotation process: used to process complex phosphate ore, first float out phosphate minerals, and then float out gangue minerals. This process can separate different types of minerals in multiple stages.

④ Reverse flotation process: Contrary to direct and reverse flotation, this process has good adaptability and can process phosphate ore containing more gangue minerals.

⑤ Double reverse flotation process: Two-step reverse flotation first removes gangue minerals and then removes other impurity minerals. It is suitable for processing low-grade phosphate ore and can effectively improve the grade and recovery rate of phosphate ore.

⑥ Stage grinding, stage beneficiation: This process can improve the efficiency of phosphate ore separation and is used to process phosphate ore with poor dissociation.

3. Chemical beneficiation process

Separate phosphate ore and gangue materials through chemical reactions, including partial acidification method, thermal decomposition method and activation-promoted release method.

① Partial acidification method: The acidic solution partially acidifies the phosphate ore, and the gangue minerals are dissolved or converted, thereby achieving the separation of phosphate ore and gangue minerals.

② Thermal decomposition method: The gangue minerals in the ore are decomposed by high temperature to generate meltable products that are easy to separate.

③ Activation-promoted release method: It is mainly based on the activation-promoted reaction of phosphate minerals and gangue minerals to increase their dissolution rate and achieve the separation of phosphate ore and gangue minerals.

With the gradual increase of medium and low-grade phosphate ore resources, phosphate beneficiation technology will be more efficient, green and low-cost in the future.

1. Efficient utilization of medium and low-grade phosphate ore

High-quality phosphate ore resources are constantly being developed and utilized, and are gradually becoming exhausted. Therefore, the development and utilization of medium and low-grade phosphate ore will become the focus of the beneficiation industry. How to improve the recovery rate and grade of such ore will also become the focus of research.

2. Innovative application of process combination flow

The combined flow of multiple beneficiation processes has been widely used in beneficiation plants. By combining the advantages of different beneficiation processes, phosphate minerals and gangue minerals can be efficiently separated to improve resource utilization.

3. Research on green and environmentally friendly beneficiation technology

The strengthening of global environmental awareness means that green and environmentally friendly beneficiation technology will be the focus of the development of phosphate beneficiation technology in the future. Reducing the use of reagents, reducing environmental pollution, and adopting low-energy consumption and high-efficiency beneficiation processes are the main research directions in the future.

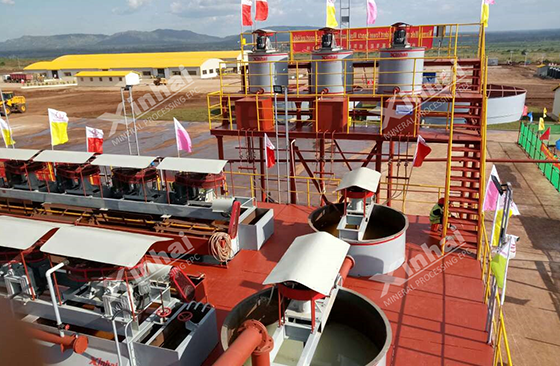

Phosphate ore beneficiation technology is of great significance for the utilization of phosphate resources. With the increase of medium and low-grade phosphate resources, the use of efficient, green and environmentally friendly beneficiation technology is an important way to improve the utilization rate of phosphate resources. Xinhai Mining will adhere to customized phosphate ore beneficiation services throughout the entire industry chain to meet the special needs of each phosphate beneficiation plant, help customers build efficient, intelligent and green phosphate beneficiation plants, and achieve high-quality development of the phosphate industry.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.