Lithium, as an important metal element, is widely used in batteries, electronic equipment, medicine, aerospace and other fields. With the rapid development of fields such as electric vehicles and renewable energy, the demand for lithium is increasing. Spodumene is one of the main raw materials for lithium-ion batteries. The development and utilization of spodumene resources are very important to meet the growing global demand for lithium.

In the ore of spodumene, there are often some magnetic iron minerals, such as magnetite (magnetite, magnetite, etc.), so these iron minerals can be separated from spodumene by magnetic separation technique. The following will introduce the general process of spodumene magnetic separation and the factors affecting magnetic separation.

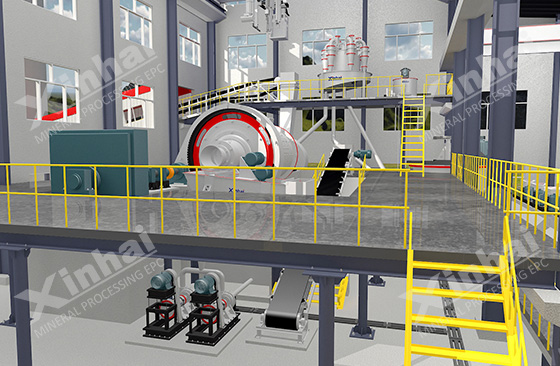

The spodumene raw ore is transported to the crusher through a belt conveyor for processing. The raw ore will be broken from larger blocks into smaller particles, which can increase the surface area of the ore and facilitate subsequent grinding and magnetic separation. Crushing is usually performed using a jaw crusher, which uses pressure to crush the ore into the desired particle size. The crushed spodumene needs to be further refined and ground in the grinding equipment to obtain a particle size suitable for magnetic separation. Grinding is usually performed using a ball mill. A ball mill grinds ore through a rotating cylinder with grinding stones or balls inside. During the grinding process, the ore is gradually refined under the action of friction and collision with the grinding stone or grinding ball to reach the required particle size.

Crushing and grinding is one of the key steps in the magnetic separation technique of spodumene ore. Its purpose is to crush the original spodumene ore into a suitable particle size to improve the effect and efficiency of magnetic separation. By increasing the ore surface area and refining the ore particles, the separation effect of the magnetic separator on spodumene and magnetic minerals can be increased, and the recovery rate of lithium can be improved.

The crushed spodumene is sent to the magnetic separator, which is equipped with magnetic rollers or magnetic materials to generate a strong magnetic field. Under the action of the magnetic field, the iron minerals with strong magnetism will be adsorbed by the magnetic force and will be adsorbed on the magnetic roller or magnetic material, while the spodumene will not be affected by the magnetic force and will be discharged through the discharge port of the magnetic separator. Concentrates containing iron minerals obtained from magnetic separators require further processing. The iron minerals in the spodumene can be effectively removed by spodumene magnetic separation, and the purity of the spodumene and the recovery rate of lithium can be improved. This is one of the important steps in the pretreatment of spodumene ore, which provides better raw materials for subsequent lithium extraction and processing.

After the magnetic separation process, the resulting magnetic concentrate contains magnetic minerals and spodumene that have been separated. First, the magnetically separated concentrate is processed to remove residual magnetic minerals and increase the purity of the spodumene. Magnetically separated concentrates may require further crushing and grinding. This can further refine the ore particles and improve the purity and recovery of spodumene.

In the concentration process, flotation techniques are often used. Flotation is to make the surface of spodumene and other non-magnetic minerals hydrophilic by introducing an appropriate flotation agent into the ore, so as to realize the separation of spodumene and non-magnetic minerals. This can further increase the spodumene concentration. After flotation, the concentrate obtained usually needs to be filtered to separate solids and liquids. The filtered solid can be further dried to obtain dry spodumene concentrate.

Depending on the specific requirements and product specifications of the spodumene ore, further processing of the concentrate may be required. This may include repeated processes of grinding, magnetic separation and flotation to further improve the grade and purity of the spodumene. The specific concentration process will vary according to the characteristics of the ore and product requirements.

1. Magnetic susceptibility: the magnetic susceptibility of spodumene ore determines its response to a magnetic field. Higher magnetic susceptibility results in stronger magnetic attraction, making the separation process easier.

2. Particle size: the particle size of spodumene ore will affect the efficiency of magnetic separation. The finer particles have a larger surface area and better contact with the magnetic field, resulting in improved separation performance.

3. Mineralogy and mineral composition: the presence of other minerals in the ore and their magnetic properties may affect the magnetic separation process. Certain minerals may have similar magnetic properties to spodumene, making separation more challenging.

4. Magnetic field strength: the magnetic field strength used in the magnetic separation process will affect the magnetic force on the particles. Stronger magnetic fields can improve separation efficiency, but may also increase equipment cost.

5. Type and configuration of magnetic separator: the selection of a magnetic separator and its configuration, such as the number of magnetic poles, belt speed, and position of magnetic elements, will affect the separation process. Different magnetic separators have different capabilities in handling specific particle sizes and magnetic properties.

6. Feeding speed and slurry density: the speed at which ore enters the magnetic separator and the slurry density (the concentration of solids in the slurry) will affect the separation efficiency. Optimal operating conditions should be determined to achieve the desired separation results.

7. Water quality and pH: the quality of the water used in the magnetic separation process, including its pH, affects the performance of the process. Contaminants or high acidity/alkalinity levels may affect the magnetic properties of minerals or cause equipment corrosion.

8. Process optimization: factors such as residence time, magnetic separator adjustment, and overall process optimization can significantly affect the efficiency and effectiveness of the magnetic separation process.

Considering and optimizing these factors above are important steps to achieve the desired separation efficiency and concentration quality of spodumene ore magnetic separation technique. The specific process steps and equipment used may vary depending on the characteristics of the spodumene ore, the requirements of the product specification, and the specific needs of the operation. The above steps are a general overview of the spodumene ore magnetic separation technique. Xinhai Mining suggested that before deciding on the spodumene magnetic separation process, the mineral processing test and analysis of the ore should be carried out to determine the composition and selectability of the ore. Xinhai Mining can customize lithium ore beneficiation process and equipment for you, welcome to consult.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.