Scheelite often exhibits a complex symbiotic relationship with calcium-containing gangue minerals such as calcite and fluorite. Because the planktonic properties of these gangue minerals are similar to those of scheelite, it is difficult to separate these ores. It can be seen that the effective separation of scheelite and calcium-containing gangue minerals is the key to scheelite flotation. This article will introduce two kinds of scheelite flotation technologies and the factors that should be paid attention to in scheelite flotation, to help you better understand scheelite flotation separation technique.

Normal temperature flotation is used in the flotation stage of scheelite coarse concentrate. A large amount of water glass is added to the concentrated scheelite coarse concentrate, and it is diluted and selected after a long period of strong stirring. This method does not need to be heated, so the scheelite concentration process can be simplified, avoiding the loss of tungsten during dehydration and drug removal, and ensuring the recovery rate of scheelite. , can enhance the continuous effect on sulfide ore and calcium gangue minerals to obtain high-grade scheelite concentrate. When the normal temperature flotation method is used in roughing operations, it can increase the roughing enrichment ratio of scheelite, discard gangue minerals to a large extent, and realize pre-enrichment of scheelite. The room temperature beneficiation method is mainly used in scheelite deposits where quartz is the main gangue mineral. This method can also be used for scheelite-fluorite-calcite type scheelite ore. The process of this method is simple and the cost of beneficiation is low.

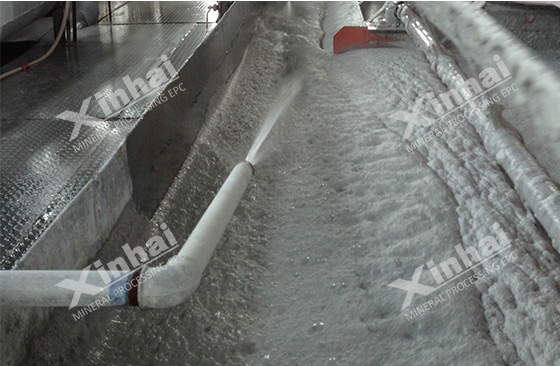

When heating and refining scheelite, it is necessary to concentrate the coarse concentrate to 50%-60%, and then add a large amount of water glass. After stirring vigorously at a high temperature of 90°C for one hour, add water to dilute, and then dehydrate and dedrug flotation. The purpose of flotation separation of scheelite and gangue minerals is achieved by utilizing the different analytical speeds of the chemical film adsorbed on the surface of different minerals. This method has strong adaptability to ore, and the beneficiation index is high and stable.

When flotation scheelite, four factors need to be considered: ore grinding fineness, flotation concentration, pH regulator and flotation temperature.

1. Grinding fineness

Scheelite is brittle and easy to over-grind, so special attention should be paid to the control of the grinding fineness during the grinding process. If only flotation technology is used to obtain all high-grade concentrates, the grinding particle size needs to be finer, and the fine-grained scheelite is dissociated to achieve monomer dissociation. If the gangue minerals of scheelite are mainly calcite, excessive ore grinding will make the slurry muddy, which is not conducive to the process of beneficiation.

2. Flotation concentration

The flotation effect is better when the concentration of scheelite dressing pulp is 33%-35%. If the pulp concentration exceeds 35%, the grade of coarse ore concentrate will drop sharply, the floating product will increase slightly, and the recovery rate will also increase slightly. Flotation index of scheelite. When the selected concentration is 20%, it is beneficial to improve the flotation index of scheelite.

3. pH adjuster

Scheelite flotation is generally carried out under alkaline conditions, and the flotation effect is better when the pH value is between 8.5-10. If the pH value of the slurry is lower than 9, silicate minerals are easy to float; when the pH value is higher than 10, minerals such as carbonates and fluorite are easy to float, and the foam is easy to dissipate, resulting in the loss or consumption of coarse scheelite of collectors.

4. Flotation temperature

Temperature is an important factor affecting the flotation operation index, and the temperature will affect the speed of the flotation reaction. For example, in the slurry at a higher temperature, the fatty acid collector can be better dispersed, and at the same time, the speed of interaction with the mineral surface is accelerated, the collection capacity is enhanced, and the selectivity is weakened. When flotation scheelite, the temperature is more suitable at 20-25 ℃.

The above content is the normal temperature flotation separation technique and heating flotation separation technique of scheelite, as well as the factors that should be paid attention to in the flotation of scheelite. In actual production, the specific scheelite beneficiation technology should be determined according to the nature of the ore and the requirements of the beneficiation plant. Xinhai Minings recommends beneficiation test to determine ore composition and mineralogy properties, and then customize the design of scheelite beneficiation plan. Xinhai Minerals can provide you with general contracting services for scheelite production and processing. Welcome to leave a message for consultation.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.