In the development of the heavy metal industry, copper, lead, and zinc metal ores are important resources, and their effective mining and utilization are of great significance to economic and technological progress. However, the typical characteristics of copper-lead-zinc metal deposits in many areas are poor, fine, miscellaneous and scattered, and this trend is becoming increasingly obvious. This article discusses the methods and measures to optimize the copper-lead-zinc preferential flotation technology through a case study of a certain copper-lead-zinc mine, aiming to provide valuable reference for relevant workers.

There are many types of metal minerals in copper-lead-zinc ores, with complex and changeable compositions. The main metal minerals include sphalerite, galena, etc. In addition, the ore also contains chalcopyrite, pyrite, magnetite, pyrrhotite, hematite, limonite, marcasite, rutile, ilmenite, chalcocite, lead alumite, etc. The content of these metallic minerals is low and the intercalation relationship is complex, making the mineral processing process difficult.

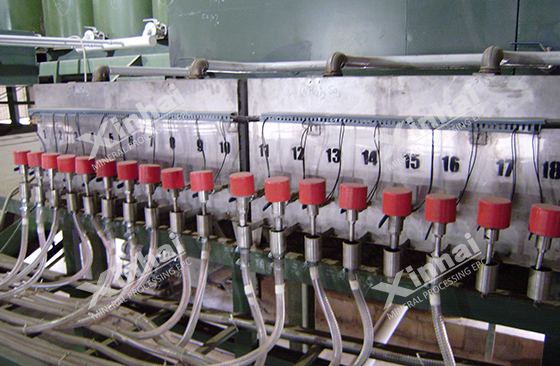

A certain copper-lead-zinc polymetallic sulfide deposit is a typical complex polymetallic sulfide ore with the distinctive characteristics of being poor, fine, miscellaneous and scattered. The particle size distribution in the mining area is poor in uniformity and the degree of oxidation is high, which restricts comprehensive recycling and mineral processing. In order to solve these problems, the mine adopts copper-lead-zinc mixed flotation technology. The specific process is copper-lead-zinc mixed flotation → mixed concentrate regrinding → copper-lead separation. This separation process can effectively solve many complex problems such as grinding and flotation, and can achieve the ideal separation of copper, lead and zinc metals, while improving the recovery quality and efficiency of concentrates.

1. Using mixed flotation technology

The copper-lead-zinc mixed flotation technology first carries out mixed flotation on the ores, and then regrinds and separates the mixed concentrates. This method can effectively solve complex problems such as grinding and flotation, and improve the metal separation effect of copper-lead-zinc ore. Through many experiments, the optimal mixed flotation process was determined to ensure the technical indicators of comprehensive recovery and mineral processing.

2. Optimize flotation reagents

Collecting agent is a key flotation agent in the flotation process, and its selection and use directly affect the flotation effect. The collector changes the hydrophobicity of the mineral surface so that the minerals adhere to the bubbles, thereby achieving flotation. Experiments have shown that within a certain concentration range, increasing the collector concentration will increase the flotation recovery rate of minerals. Therefore, optimizing the type and dosage of collector is crucial to improving the flotation effect of copper-lead-zinc ore.

3. Adopt regrinding process

The regrinding process is an important step in improving the separation effect of copper, lead and zinc. After the mixed concentrate is reground, the degree of dissociation of the mineral monomers increases and the flotation effect is significantly improved. Determining the optimal regrinding fineness through experiments can improve the recovery rate and grade of copper, lead and zinc.

1. Increase capital investment

In order to solve the problem of insufficient funds for exploration and comprehensive recycling, it is necessary to raise funds through various channels, strengthen the mining rights market, and increase the proportion of commercial exploration operations.

2. Introduce modern scientific and technological means

Actively research and promote comprehensive recovery and beneficiation technology for medium and low-grade copper, lead and zinc ores, and use modern scientific and technological means to improve the utilization rate and economic benefits of ore resources.

3. Environmental protection and governance

In the process of mine development, environmental protection must be included as an important assessment indicator and the environmental protection and management of mines must be strengthened. Ensure that environmental protection measures are in place by strictly implementing the access system for mining resource development.

4. Strengthen management and supervision

Strengthen mining administration and improve the ability to rationally develop, recycle and utilize mineral resources. Regularly conduct in-depth inspections and surveys in the mines to identify problems and promptly handle and improve them.

The above content is a brief introduction to the mineral processing method of a certain copper-lead-zinc ore, and proposes methods and approaches to improve the utilization rate of copper-lead-zinc ore resources. In actual production, it is necessary to continuously optimize the mineral processing process and equipment, which not only improves the resource utilization rate , reducing production costs and significantly improving economic benefits. The mineral processing plant should also continue to pay attention to the innovation and application of lead-zinc ore mineral processing technology and promote the green, efficient and intelligent development of mineral processing technology.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.