As an important strategic resource, high-purity quartz sand is an important raw material in the fields of optical fiber communication, microelectronics, and solar energy. Quartz ore has many impurities, and generally coexists with various impurities, among which iron tails are common impurity minerals, so iron removal and purification of quartz sand is the key. Below, Xinhai Mining will sort out the production process of high-purity quartz sand for iron removal!

At present, the common quartz sand iron removal production processes mainly include: mechanical scrubbing iron removal, magnetic separation iron removal, flotation iron removal, acid leaching iron removal, ultrasonic iron removal and microbial iron removal.

The mechanical scrubbing method of quartz sand is accomplished by means of external mechanical force and the collision and friction between mineral particles to remove the thin film iron on the surface of quartz sand and the iron-containing impurities adhering to its surface. There are two types of mechanical scrubbing methods: rod scrubbing and mechanical scrubbing. As for which one to choose, it depends on the nature of the quartz sand ore.

There are two types of magnetic iron removal for quartz sand: dry iron removal and wet iron removal. Among them, the wet magnetic separation mainly adopts the wet strong magnetic separator, which can remove the weak magnetic impurity minerals such as hematite, limonite and biotite including the continuous particles to the greatest extent (using the wet strong magnetic machine at 10,000 Å selected above). Use a weak magnetic separator to separate the strong magnetic minerals mainly magnetite. However, this iron removal method consumes a lot of power, the medium is easy to wear, the production water consumption is large, and the maintenance is difficult.

Dry magnetic separation iron removal often uses dry magnetic separator to complete the iron removal operation, the process is convenient to operate, and the operation and maintenance costs are lower than those of wet type.

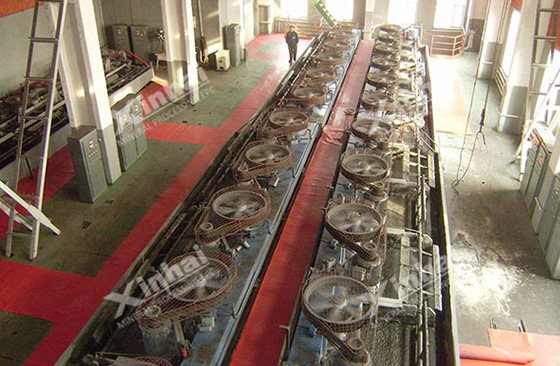

There are three types of iron removal by quartz sand flotation, which are fluorine-acid method, fluorine-free acid method and fluorine-free acid method. Among them, the fluorine-acid method has good flotation effect, easy control, and stable indicators, which is why it is widely used. However, fluoride ions have a great erosion effect on the land and damage to the surrounding ecological environment. The fluorine-free acid method removes fluoride ions and reduces the damage to the environment. The production index of this method is stable. However, strong acid is very serious to the corrosion of mineral processing equipment, which cannot be ignored. The fluorine-free and acid-free method is to create a high-concentration pulp flotation environment through the reasonable deployment of anion and cation collectors under natural pH conditions to achieve the purpose of preferential flotation of impurity minerals. However, this method has high requirements on raw sand treatment and is not easy to control in production, so it has not been widely used yet.

The acid leaching iron removal method utilizes the property that quartz sand is insoluble in acid (except HF), while iron-containing impurities are easily dissolved by acid, so that good quartz sand concentrate can be obtained. Generally, the commonly used acids for pickling quartz sand are sulfuric acid, hydrochloric acid, nitric acid and hydrofluoric acid.

Ultrasonic iron removal method is to use ultrasonic technology to remove the secondary thin film iron on the surface of quartz particles. Generally, the ultrasonic treatment is about 10 minutes, and the iron removal rate can reach 46% to 70%. When using ultrasonic iron removal, care should be taken to remove the waste liquid in time to prevent secondary adhesion and reduce the iron removal effect.

For the removal of iron from quartz sand, the ultrasonic method is relatively expensive. However, this method can be used for those fields that require high purity and low consumption of quartz sand.

Microbial iron removal method is to use microorganisms to leach thin film iron or disseminated iron on the surface of quartz sand particles to obtain good quartz sand concentrate. The process is a new technology, which is still in the experimental stage. For the research surface, microorganisms such as Aspergillus niger, Penicillium, Pyriformis, Pseudomonas, Bacillus, Bacillus polymyxa, and Lactobacillus can be used to leach iron oxide on the quartz surface.

The above are several common iron removal methods in quartz processing flow. In the actual concentrator, it is not possible to choose blindly, but should be determined according to the impurities contained in the quartz sand. Therefore, Xinhai Mining recommends to conduct mineral processing test first, and design and customize a suitable quartz sand production process plan through experimental analysis.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.