Chengde, in Hebei province, has a unique historical site, contains profound cultural deposits, and is a famous historical and cultural city. At the same time, Chengde is also a city rich in mineral resources, with vanadium, titanium, iron, molybdenum, silver, lead, gold, as well as non-metallic mineral resources such as fluorite and phosphate. Recently, the 2000TPD iron concentrate desulfurization plant was successfully completed. From the early stage of the project to the determination of the beneficiation scheme process and the final implementation of the beneficiation project, Xinhai adheres to the customer-first service attitude and adheres to the service concept of "what you need what we can do" to help customers build a high-quality mineral processing project.

At the end of 2020, the customer of the project contacted Xinhai and sought technical support from Xinhai. The customer said that the iron concentrate produced by the project has a high sulfur content, which is difficult to meet the subsequent use needs. They hope to obtain more qualified iron concentrate products through the new process solutions. After a preliminary understanding of the project information, Xinhai provides customers with a general technical solution and quotation. The customer is very satisfied with this, and has signed a subsequent project contract with Xinhai.

Raw ore properties: The raw ore of project is mainly iron concentrate powder, with iron grade of about 63.5% and sulfur grade of about 0.37%.

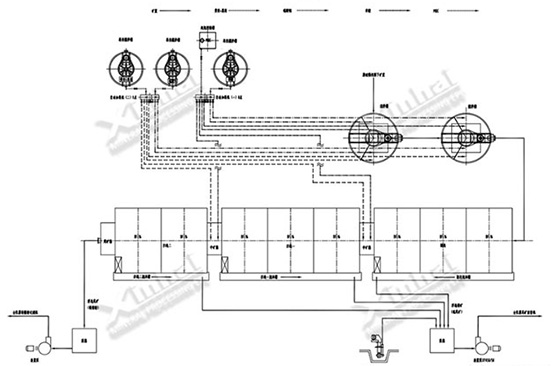

Process flow: the flotation process of one rough and two sweeps

Main equipment: BF flotation machine, agent mixing tank, wear-resistant slurry pump, automatic dosing machine, etc.

1. Mineral beneficiation test

According to the test samples sent by the customer, Xinhai has prepared the test samples, and obtains three parts of samples: test sample, screening and analysis sample and test sample. And the original process of the Xinhai simulation project site is to prepare iron concentrate to maintain the stable and uniform iron grade and sulfur grade of the flotation original ore. After laboratory analysis and screening test, the sulfur minerals in the raw ore are evenly distributed, and the main purpose is reducing the sulfur grade. After the comparative analysis of multiple tests, Xinhai has proposed the appropriate process scheme and pharmaceutical system for this project. The flotation operation of one rough and two sweeps is mainly used, using yellow medicine and black medicine as mixed trap agent flotation of sulfur minerals, and using copper sulfate and oxalate as combined activators. It can not only effectively reduce the cost of the agent, but also ensure the sulfur removal effect of the concentrate.

2. Project design

After determining the benefication process, Xinhai Mining Design Institute makes the overall planning for the project according to the actual situation provided by the customer on the site, carries out the customized construction drawing design, and carried out the reasonable layout of all kinds of equipment and pipeline lines.

3. Equipment manufacturing and procurement

In order to make the equipment meet the needs of the process, Xinhai customizes adjustment and transforms the selected equipment, and the main and auxiliary equipment of the flotation production line of the project to reduce the equipment energy consumption, improve the equipment yield and extend the stable operation time of the equipment.

4. Equipment packing and shipment

After the manufacturing and procurement of the equipment related to the project, Xinhai assigns an experienced packaging and shipping team to responsible for the packaging and shipping process of the project. Xinhai uses the number and manual management system to ensure that the equipment and spare parts are complete, according to the site installation needs and transportation needs of the classification of packaging, to ensure the safety of the equipment.

5. Equipment commissioning and delivery

With the arrival of the project equipment, Xinhai has appointed an experienced team to the project site to assist in the installation and commissioning. Within half a month, the installation and commissioning team completes the installation of all the equipment, and officially puts it into operation through the commissioning of process indicators, explaining the efficiency and professionalism of Xinhai to customers with practical actions.

Since its operation, the project has been in stable operation and has reliable equipment quality. After completing the process index debugging, the sulfur grade in the iron concentrate powder was reduced to below 0.15%, and the customer was very satisfied with this. In addition, during the progress of the project, the Xinhai team also impressed the customers with their professional skills, professional attitude and responsibility sense.

1. Long-term consideration based on the actual situation

In order to ensure that the concentrator can obtain sustainable and stable production indicators after production, Xinhai is based on the actual production situation of the project from the beneficiation test. The actual process of the original mine sent by the customer is used to simulate the index test to escort the long-term production of the concentrator.

2. Cooperation orderly and put into production as soon as possible

It only takes less than half a year from the signing of the project to the operation of the selection plant. During the period, the test, design, production, installation and commissioning were connected in an orderly series, achieving another breakthrough of "Xinhai speed".

3. Complete the project targets beyond expectations

The project expects the sulfur grade in the concentrate to be reduced to below 0.2%. Under the professional guidance of Xinhai technical team, the sulfur grade of iron concentrate powder in the actual production can be reduced to less than 0.15%, or even reach 0.065%, greatly exceeding the expected index of the project.

The success of Hebei 2000TPD iron concentrate desulfurization and dressing plant project is another medal obtained from Xinhai. As the proposer and practitioner of "Whole Mining Whole Industry Chain Service (EPC + M + O)", Xinhaiis always guided by customer needs and provides customers with scientific and customized concentrator service solutions. In the future, Xinhai will continue to take the dissemination of the correct concepts and methods of mine construction as its own responsibility, promote the implementation of the Xinhai scheme, and effectively provide global customers with more perfect, professional and in place of the whole mining industry chain services (EPC + M + O)!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.