Copper ore is one of the most important metal ores in the world and is widely used in the fields of electricity, construction, transportation, metallurgy, etc. The choice of copper ore dressing method will directly affect its recovery rate and economic benefits. For different copper ores, different ore beneficiation methods need to be selected according to their mineral composition and physical and chemical properties. The types of copper ores include chalcopyrite, chalcocite and other types of copper ores. The following will introduce the dressing methods of these copper ores and analyze their difficulty and economic benefits.

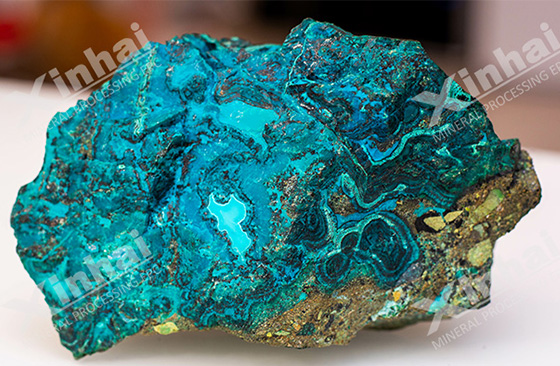

Common types of copper ores in nature include chalcopyrite, chalcocite, bornite, and copper ore lamp. Their mineral composition and physical and chemical properties are very different, and their beneficiation methods are also very different.

- Chalcopyrite: It is a copper-containing sulfide mineral and one of the common types of copper ore. Due to its high mineral density, chalcopyrite has good flotation properties.

- Chalcocite: It is mainly composed of copper and sulfur. The chalcocite ore is relatively rough and contains more impurities, so its beneficiation method is also more complicated.

Other types of copper ore: Common copper ores include bornite and copper ore lamp. They have different mineralogical characteristics and beneficiation methods.

The ore beneficiation method of chalcopyrite is mainly flotation, and other beneficiation methods include gravity separation and sintering.

1. Flotation method: After adding flotation agents such as collectors and frothers to chalcopyrite during flotation, copper ore particles adhere to the bubbles to form foam products, thereby separating copper minerals from gangue minerals. Chalcopyrite has strong flotation properties, and the flotation method can improve the copper recovery rate. Controlling factors such as reagent concentration, pH value, and bubble size during flotation can improve the ore beneficiation effect.

2. Gravity separation method: When the particle size of chalcopyrite is coarse, gravity separation can be used to remove light minerals and impurities, further improving the quality of copper minerals.

3. Sintering method: When chalcopyrite is difficult to recover directly by flotation, roasting can be used to convert chalcopyrite into copper oxide or other soluble copper compounds, and then smelting. This method can reduce the sulfur content in the ore and improve the ore beneficiation.

The ore beneficiation of chalcopyrite is relatively simple, and a high recovery rate can be obtained by flotation. However, the flotation process is also affected by factors such as ore grade, flotation reagents, and types of associated minerals. The flotation process of chalcopyrite is mature and stable, and the investment cost of flotation equipment is low, which can be applied to large-scale production. When chalcopyrite is easy to be selected, the beneficiation recovery rate is high and the economic benefits are significant.

In actual production, the commonly used ore beneficiation methods for chalcocite are flotation, gravity separation and acid leaching.

1. Flotation: Due to the poor flotation properties of chalcocite, specific reagents need to be added during the flotation process to improve the flotation effect. Since chalcocite is often accompanied by impurities such as iron and sulfur, care should be taken when selecting reagents to avoid mutual influence between minerals.

2. Gravity separation: Suitable for processing chalcocite with larger particle size. Due to the presence of a large number of sulfide impurities in chalcocite, it will affect the separation effect of gravity separation.

3. Acid leaching: Use strong acids such as sulfuric acid to dissolve chalcocite and then extract copper. The acid leaching method mainly treats low-grade ores, which can effectively remove some associated impurities and further improve the purity of copper ore.

The beneficiation of chalcocite is difficult, its mineral particles are small, there are more associated minerals, and its flotation properties are poor. Although the acid leaching method can effectively improve the recovery rate of copper ore, its operating conditions are strict and the cost is high. The economic benefits of chalcocite ore beneficiation are affected by ore grade and beneficiation method.

Flotation method: It has good applicability to chalcopyrite and can obtain a higher recovery rate. For chalcopyrite and other associated ores, its flotation effect is poor, and other methods such as acid leaching and gravity separation are needed to improve the recovery rate.

Gravity separation method: It is used for copper ores with larger particle size, and can effectively separate copper ores in chalcopyrite and chalcopyrite.

Acid leaching method: It is used to treat low-grade ores and is often used for ores that are difficult to float, such as chalcopyrite.

In the copper ore dressing process, common technical challenges mainly come from uneven ore particle size distribution, interactions between minerals, and the influence of associated minerals. For the above problems, the optimization and improvement of the ore beneficiation process and the use of advanced equipment are adopted to improve the beneficiation effect.

In summary, different types of copper ores have obvious differences in the selection of beneficiation methods. According to the mineral composition of the ore and the difficulty of beneficiation, a single beneficiation process or a combination of multiple beneficiation processes can be used to improve the beneficiation efficiency and recovery rate of the copper ore and improve the economic benefits of the overall beneficiation plant. With the continuous development of technology, copper ore beneficiation technology will be more efficient and environmentally friendly in the future. However, before determining the copper ore beneficiation technology, beneficiation tests should be carried out to provide a theoretical basis for the determination of the beneficiation process.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.