Scheelite is an important tungsten resource, and its mineral processing technology is crucial in mineral development. Among them, heated flotation and normal temperature flotation are two commonly used flotation technologies for treating scheelite. Each flotation technology has its own characteristics. This article will deeply explore the process flow, technical characteristics and applicability of these two flotation methods to help better understand the optimization direction of scheelite mineral processing technology.

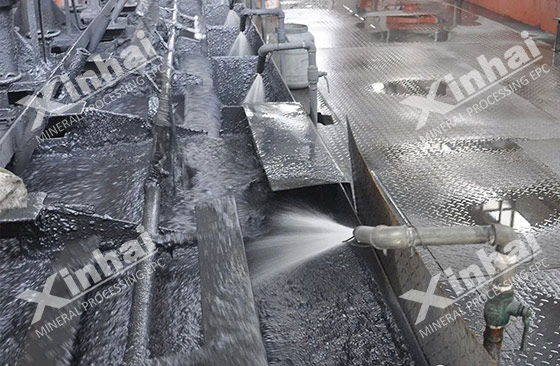

The core of heated flotation technology is to achieve mineral separation by heating. The specific process includes concentrating the concentrate obtained from roughing, and the concentration of the concentrated pulp is maintained between 60% and 70%. Next, a large amount of water glass is added to the pulp as an inhibitor, and the pulp is stirred under high temperature conditions. After sufficient stirring, the pulp is diluted and floated at room temperature. The uniqueness of heated flotation method is that the collector film formed on the surface of different minerals has different decomposition speeds at high temperatures, so it shows different inhibition, and finally achieves mineral separation.

The advantage of this flotation technology is that it can effectively separate scheelite from gangue minerals, especially in some complex ores where scheelite is difficult to dissociate from the associated minerals. The heated flotation method can provide a stable recovery rate. However, its main disadvantages are high working environment temperature, complex operation, high energy consumption, and high cost. In addition, the operating environment is relatively harsh and the process flow is difficult to control, so mines gradually turn to other low-cost and easy-to-operate flotation methods.

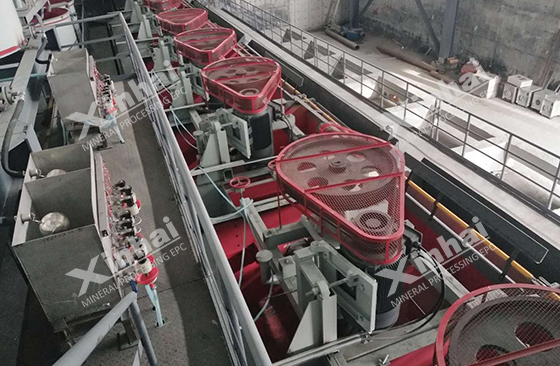

Compared with heated flotation technology, room temperature flotation technology has gradually become the mainstream technology for scheelite beneficiation. Room temperature flotation method does not require heating of slurry, significantly reduces energy consumption, improves the operating environment, and the process is simple and easy. The two representative operating methods of this process are as follows:

Alkaline medium flotation technology

This process uses sodium hydroxide or sodium carbonate to adjust the alkaline environment of the pulp, uses metal salts as activators, and uses water glass as a depressant. During the flotation process, a mixed collector is used instead of the traditional single collector, thereby improving the recovery effect of the mineral. The alkaline medium helps to disperse the mineral particles and promote the separation of various minerals in the pulp.

Combined depressor flotation technology

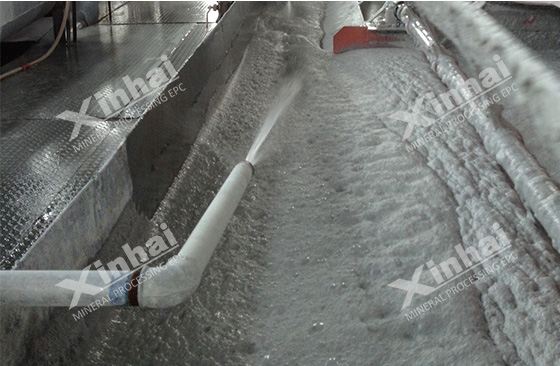

This process is also carried out in an alkaline medium, but on the basis of using water glass, it combines macromolecular organic matter such as baked gum and tannin as a combined depressant. This combined depressant has a stronger selective inhibitory effect on gangue minerals, further improving the separation efficiency of flotation. At the same time, the mixed collector shows better collection ability than the single collector, which helps to improve the recovery rate and purity of the concentrate.

The innovation of these two room temperature flotation methods is to use the combined effect of alkaline medium and multiple chemical reagents to improve flotation efficiency. In particular, the application of combined depressants effectively solves the problem of poor effect of sodium silicate depressants in traditional flotation processes. At the same time, the application of mixed collectors further enhances the floatability of scheelite and reduces mineral losses.

In contrast, heated flotation has gradually lost its advantages due to its high energy consumption and complex operation process, while normal temperature flotation has been widely used in scheelite beneficiation plants due to its low cost, high efficiency, and easy operation. Although heated flotation still has a high separation capacity in some special ores, normal temperature flotation is significantly better than heated flotation in terms of economy and environmental friendliness.

The following is a comparison of the two methods:

| Heating Flotation Method | Normal Temperature Flotation Method | |

| Technical Parameters | Heating flotation method | Normal temperature flotation method |

| Energy Consumption | High, requires a lot of heat energy | Low, no need for additional heating |

| Operation Complexity | Complex, difficult to operate | Simple, easy to operate |

| Environmental Impact | High temperature working environment is bad | Operate at normal temperature, environmentally friendly |

| Application | Suitable for difficult to handle complex ores | Applicable to various types of scheelite |

| Cost | High, the heating process increases costs | Low, simplified process, low cost |

With the continuous advancement of mine beneficiation technology, the flotation process of scheelite is also being optimized. Normal temperature flotation method has gradually become the mainstream due to its low cost and high efficiency, and there have been more innovations and improvements in the selection of reagents and process design. In the future, the beneficiation process for different types of scheelite will be more flexible and efficient to improve resource utilization, reduce environmental impact and production costs.

At the same time, with the development of low-grade and complex ores, combining multiple flotation technologies, using new reagents and optimizing process flows will become an important direction for scheelite beneficiation technology. In particular, the use of green and environmentally friendly reagents and high-efficiency equipment in the flotation process will further promote the development of scheelite beneficiation technology in a more environmentally friendly and efficient direction.

Both heated flotation and room temperature flotation technology have their unique process characteristics and scope of application. In today's environment of increasingly stringent resource development and environmental protection requirements, room temperature flotation has gradually become the mainstream technology for scheelite beneficiation with its advantages of low cost and high efficiency. Although heated flotation still has application value in the treatment of some special ores, its high energy consumption and complex operating procedures limit its large-scale application. In the future, with further technological innovation, the beneficiation process of scheelite will be more efficient and green, promoting the sustainable utilization of tungsten ore resources.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.