As the exhaustion of high-grade gold ore, researching middle-low grade and refractory gold ore and strengthen the traditional gold processing undoubtedly have become the main trend in the global gold processing industry.

There are three common gold processing methods widely used in many gold processing plants according to the different types of gold ore characteristics and user requirements, includes gold cyaniding process, gold flotation process, gold gravity separation process.

Gold cyaniding process is a kind of main modern gold processing method that adopting cyanide as the leaching liquid to extract gold from ore or concentrate. The gold cyaniding process can be divided into agitating cyanidation process and leaching cyanidation process. Agitating cyanidation process is applied to treating the tailings after gravity separation, amalgamative tailings and flotation gold-bearing concentrate, or applied to full slime cyanidation. Leaching cyanidation process is used to treat flotation tailings and low-graded gold ore.

1. Agitating Cyaniding Process

Among them, the agitating cyaniding process mainly includes two types of the gold extraction process. One is the cyanide-zinc replacement process (CCD method and CCF method), which uses zinc powder (silk) to replace and recover gold after continuous counter-current washing. Another is the all-slime cyaniding (CIP process and CIL process), which adopts activated carbon to absorb and extract gold from cyanide pulp directly without filtration and washing.

Cyanide-zinc replacement Process (CCD method and CCF method):

Cyanide-zinc replacement process (CCD method and CCF method) is to use zinc powder (silk) as the reducing agent to replace gold and silver from the leaching liquid, which mainly includes material preparation, washing (solid-liquid separation), purification, deoxidation, replacement, acid pickling and smelting.

All-slime cyaniding process:

All-slime cyaniding process (CIP process and CIL process) is to add the activated carbon into the cyanide slurry, and the dissolved gold is absorbed on the activated carbon, and then the gold is extracted from the activated carbon. Here are seven main steps of all-slime cyanidation process: preparation of leaching material, agitation and leaching, countercurrent carbon adsorption, desorption of gold-loaded carbon, electrodeposition and electrolysis, smelting, carbon regeneration.

The leaching cyaniding method is also one of the gold cyaniding leaching processes. The cyanide solution is permeated through the ore layer, so the gold is leached from the ore. The leaching cyanidation method is suitable for placer deposits and soft porous material. The leaching cyaniding method can be divided to the pool leaching process and heap leaching process.

Pool leaching process:

The main percolation leaching equipment is a leachate tank, which includes a tank, iron tank or cement tank. The bottom of the pool is horizontal and turns as slightly sloping, round, rectangular or square. The tank is fitted with a false bottom made of perforated acid-proof board, which is covered with a filter cloth. And the grid that made of wood or corrosion-resistant metal strips covers on the filter cloth. When leaching, loading the ore in the pool, and adding leaching agent at the top of the pool, so the leaching liquid flows out from the false bottom part, where is used for filtering and supporting the ore.

Heap leaching process means transfer the raw ore to the prepared yard, or directly stock on the waste rock or low-grade ore, then use cyanide leaching liquid to spray or infiltrate, and the ore reacts with the cyanide leaching liquid. After several recycling of leaching liquid and repeat spray, the leaching liquid can be collected. Then, treating leaching liquid by the activated carbon or metal zinc method and the barren solution returns to heap leaching operation for reuse.

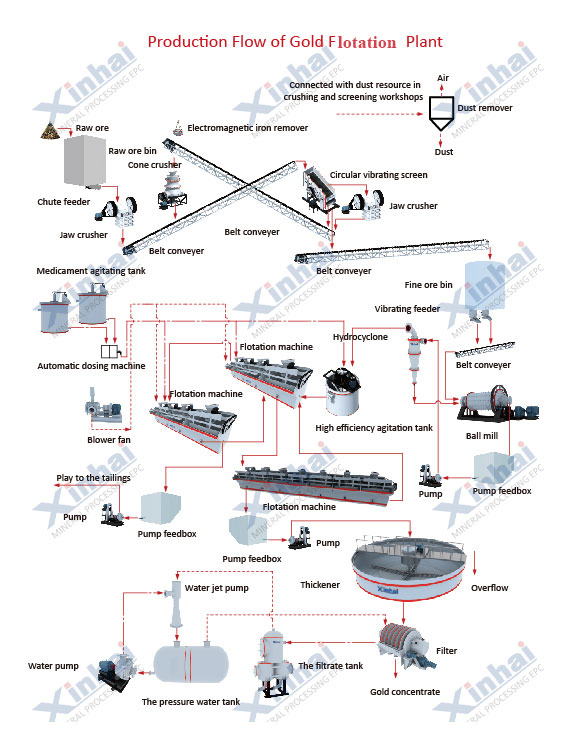

Flotation process is one of the most widely used methods for processing rock gold ore, and gold-bearing sulfide ore with high floatability. Flotation process can concentrate the gold into the sulfide minerals maximally, and the tailings can be directly abandoned, so the cost of gold flotation process is relatively low. 80 percent of rock gold ore is separated by the gold flotation process. The flotation process mainly includes several stages: dosing, agitation, air inflation and scraping.

Gold flotation process is suitable for gold-bearing sulfide ores with fine particles and good floatability. In the flotation process, sulfide ores are enriched into sulfide concentrate as the carrier of gold. Besides, the gold flotation process can also be used for the polymetallic gold sulfide ores and carbonaceous gold ores. For the refractory ores that cannot be treated directly by amalgamation or cyanidation method, a combined process including flotation process is required.

Gold gravity separation process is one of the common methods used in gold ore dressing. It achieves the separation by relying on the different proportions of material and different sedimentation velocity in the medium. In the alluvial gold mine, the gold mostly exists as the natural gold, which has large density difference with the gangue, so the gravity separation process is efficient and economic.

There are many kinds of gravity separation equipment used in the gravity separation method, such as jig, shaking table, chute gravity separation, spiral chute, centrifugal separator and wind separator, etc. There are three common gold gravity separation methods: jigging for gold extraction, shaking table for gold extraction and spiral chute for gold extraction.

The above three gold gravity separation methods are only used for monomer dissociation gold ore (alluvial gold mine). For lode gold, the joint separation process is often adopted rather than the single gravity separation, such as gravity separation – flotation process (the gravity separation process is used to assist gold extraction). In the grinding and classification circuits, using the jig, spiral chute and shaking table to recycle the coarse particles and create better conditions for the subsequent flotation cyanidation process, which is beneficial to improve the final gold index and gold recovery rate.

In gold processing, the selection of gold processing method should be determined according to the properties of the gold ore. It is suggested to conduct the mineral processing test before selecting the gold processing method, analyze the properties of the gold ore, and finally determine the gold extraction process according to the result of the mineral processing test.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.