Among all rare metals, chrome has obvious significance and necessity. At present, the common chrome ore beneficiation solution mainly includes gravity separation, magnetic separation, flotation separation, and a combined gravity-magnetic separation. Let us take everybody to understand the below solution.

From the perspective of production practice, the gravity separation solution using loose layering in the water medium is still the main method for enriching chrome ore beneficiation.

It is worth mentioning that in the process of chrome ore gravity separation, the stage grinding-gravity separation equipment separation or the combined separation process of multiple gravity separation equipments can be used according to the nature of the chromium ore to further improve the chrome concentrate grade and recovery rate.

Main gravity separation equipment: shaking table, jig, spiral chute, and centrifugal concentrator.

Due to the weak magnetic properties of chrome ore, the strong magnetic separator can be used to purify chromite. There are two main situations:

1. Under a weak magnetic field, increase the ferrochrome ratio by removing strong magnetic minerals (mainly magnetite) in the ore;

2. Under a strong magnetic field, separate gangue minerals and recover chromium ore.

When necessary, the combined weak-strong magnetic process can also be used to effectively realize the enrichment of chrome ore.

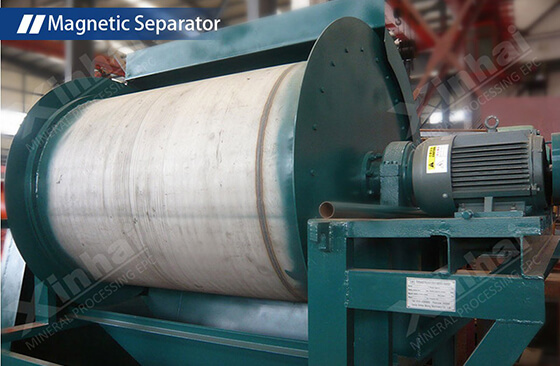

Main magnetic separation equipment: magnetic separator.

At present, the flotation solution can be used to recover the fine-grained chrome after gravity separation. Magnesium ions and calcium ions can inhibit chromium ore, which inhibition is affected by the type of cation in the slurry.

Therefore, after clarifying the type of cations in the slurry, it separates chrome ore and pyrite to select the appropriate slurry PH value, chemical concentration, inhibitor, and activator addition sequence.

Main flotation separation equipment: flotation cell.

Sometimes, a single gravity separation method cannot effectively recover chromium concentrate. At this time, the gravity separation concentrate can be reprocessed by weak magnetic separation or strong magnetic separation to further improve the grade and ferrochrome ratio of the chrome concentrate.

The above are the four common chrome ore beneficiation solutions. For chrome ore with higher chromium oxide content, single gravity separation or magnetic separation process can be adopted; for chrome ore with lower chrome oxide content, the combined gravity-magnetic separation process often obtains better indicators than a single process.

Of course, the specific chrome ore beneficiation should be determined comprehensively by the nature of the chrome ore the actual situation of the concentrator ensure the ideal beneficiation and economic benefits.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.