The tailings dry discharge is a new tailings processing process gradually emerging at home and abroad, that is, after the tailings slurry is concentrated in multiple stages, and then processed by efficient dewatering equipment such as dewatering vibrating screen to form slag with small water content, easy to precipitate, solidify and be stacked. The slag can be transported to a fixed location for dry storage.

According to different tailings types, particles, concentration and mud content, it could minimize the occupied area and save equipment investment on the premise of ensuring dry discharge to reasonably formulate tailings dry discharge process and select of tailings dry discharge equipment. Below, there are five common solutions of tailings dry discharge process to help you choose one right for you.

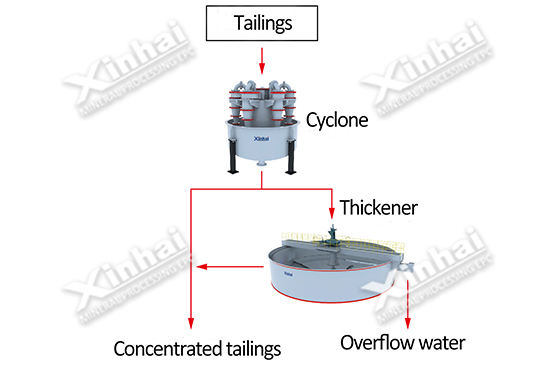

The tailings with a concentration of 10%-20% are fed into the cyclone via a slurry pump, and the overflow of the cyclone is fed into the thickener for the concentration of fine particles. The overflow of the thickener is clarified water, which is returned to the production of circulating water for reuse. The concentration of the cyclone sedimentation and the underflow of the thickener is 45%-50%.

This solution makes full use of the difference in the different particle sizes of tailings, prioritizes the concentration of large particles, improves the processing capacity of the thickener, reduces the diameter of the thickener, and saves investment. But the concentration of discharged tailings is not high and hard to be dry stacked.

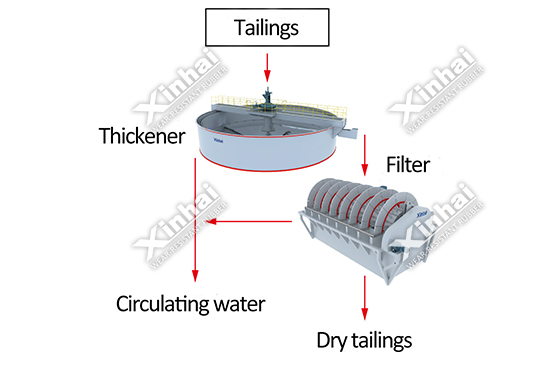

The tailings are fed into the thickener and the underflow of the thickener is fed into the filter. The filtered filter cake contains 15%-20% water and can be directly discharged in a dry-type way. The overflow water and filtered water of the thickener are returned to the production of circulating water for reuse.

The filter solution can obtain materials with low water content to achieve the purpose of direct dry discharge, and easy to transport. It is worth noting that this solution requires large-scale thickeners, which occupy a large area and high investment, so it is not suitable for the tailings process of large and medium-sized processing plants.

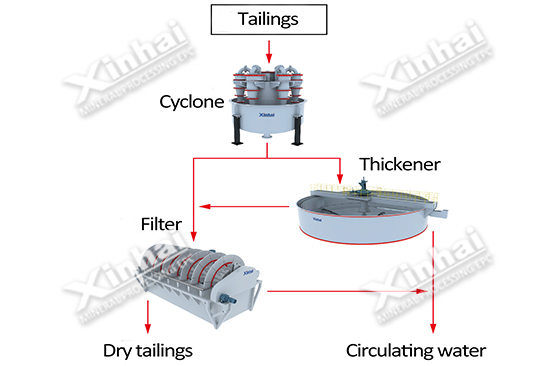

The cyclone is used as the first stage of concentration equipment. The tailings slurry is fed into the cyclone; the overflow of the cyclone is fed into the thickener; the underflow of the cyclone and the underflow of the thickener are combined to the filter, and the overflow water and filtered water of the thickener are returned to the production of circulating water for reuse. After filtration, the filter cake contains 15-20% water and can be directly discharged in a dry-type way.

The advantages of this solution are that the one-stage dewatering of the cyclone greatly reduces the workload of the thickener, clarifies the overflow water of the thickener and avoids the mudflow, and also reduces the specifications of the thickener, covers a small area and reduces the investment cost. However, the workload of the filter is large, and it needs to be equipped with a large-size filter or multiple filters, and the energy consumption is high.

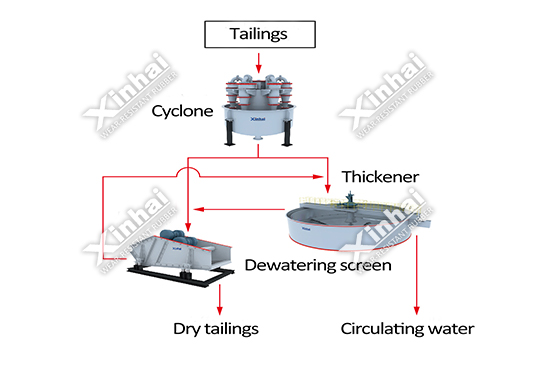

The tailings are fed to the cyclone, and the overflow from the cyclone is fed to the thickener. The overflow water of the thickener is returned to the production of circulating water for reuse, and the bottom flow of the cyclone and the bottom flow of the thickener are fed to the dewatering screen. The material on the dewatering screen contains 20%-25% water for dry discharge, and the material under the screen is returned to the thickener.

This solution uses a dewatering screen to reduce the filter equipment, which saves electricity and reduces the investment cost. However, the fine-grained materials under the dewatering screen return to the thickener to form an infinite cycle, affecting the concentration effect, making the concentrated clarified water turn muddy. Finally, the materials under the screen are discharged into the tailings storage, which fails to achieve all dry discharge.

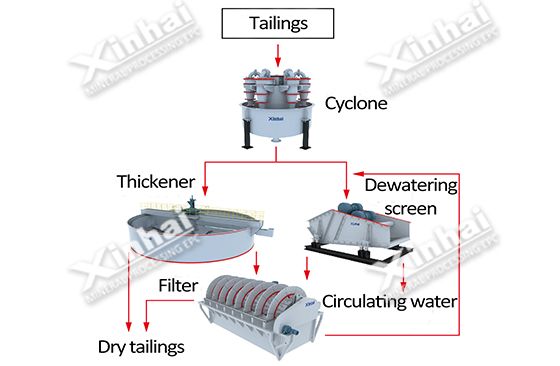

The tailings are fed into the cyclone and separated by gravity. The fine particles and water are fed into the thickener, and the clarified water of the thickener is returned to the production of circulating water for reuse; the underflow of the cyclone is fed into the dewatering screen, and the water on the dewatering screen is 15%-20% for dry discharge. The materials under the screen are fed into the filter together with the underflow of the thickener. After the filtration, the filter cake contains 15%-18% water for dry discharge. The filtered liquid and the cleaning water of the filter return to the thickener to form a closed circuit.

This solution uses cyclone and dewatering screen to classify and dewater coarse and heavy particles first before dry discharge, which reduces the workload of thickener and filter, which reduces the workload of thickeners and filters, and correspondingly reduces the specifications of thickeners and filters, covers a small area and reduces the investment cost. The materials under the screen dewatering screen are fed into the filter to ensure solid-liquid separation, which is convenient for all dry discharge to realize the long-distance transportation of tailings. The discharge liquid and the cleaning water of the filter are returned to the thickener, which not only ensures the solid particle content in the reused water, but also meets the quality of the production water.

With the release of the national “green mine” standard, the tailings dry discharge has shown great advantages in terms of economy, environment and safety, and has become an important choice for the tailings process in the future. In the actual application of the mineral processing plant, it is recommended to choose a suitable tailings dry discharge solution according to the scale of tailings, investment, etc., and tailor reasonable dry discharge equipment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.