In Alpapowder 2017 Annual Commendation Meeting, Xinhai was selected as Alpapowder's "outstanding partner".

In 19, as the "outstanding partner", Xinhai was invited to attend Weifang Alpapowder Co., Ltd. 2017 Annual Commendation Meeting. Xinhai reached a cooperation agreement with this company in long-term supply of Xinhai wear-resisting rubber products, and made new progress in promoting the win-win.

Xinhai wear-resisting rubber products

Wear resistance of rubber products depends on the content of natural rubber in rubber products and the integrity of rubber chain. As long as rubber products have high natural rubber content and the complete chain, rubber products can have high quality and excellent wear resistance.

After continuous exploration research, Xinhai successfully developed the "liquid state nano-meter formula, high frequency room temperature curing" compounding process, which broke the monopoly from international enterprise in liquid compounding monopoly for over 80 years. After verified, wear-resisting index, resilience and tear strength of Xinhai wear-resisting rubber products has reached international advanced level in the wet environment.

The comparison of Xinhai wear-resisting rubber products process and traditional rubber products process

1 Liquid phase process, the guarantee of rubber quality

Xinhai liquid refining process reduced the damage from the production process to the long chain of natural rubber molecules, and maximally protected the natural wear resistance.

Xinhai wear-resisting rubber molecular weight testing data as shown below, long chains of traditional rubber molecular chain were damaged a lot, long chains were very few, there were only a large amount of short chains.

Xinhai wear-resisting rubber molecular testing data

And the molecular weight curve of Xinhai wear-resistant rubber was the nearest to the natural rubber molecule, and it was proved that Xinhai wear-resistant rubber maximally maintained the wear resistance of natural rubber molecules.

2 Patent nano-aids, superior masterbatch guarantee

Xinhai wear-resistant rubber was adopted advanced nano-reinforcing technology, the aid was only nano-grade, which was more easily penetrated into latex and made the mixing more uniform. Therefore, only a small amount of aid ensured that the natural rubber content of masterbatch was at higher level, which made Xinhai wear-resistant rubber keep natural wear-resistence.

After testing, Xinhai wear-resistant rubber 0.25mm strip was deformed when stretched to 800%, the resilience reached 80%, and the tensile strength reached 23.5 MP!

▼ Xinhai wear-resistant rubber stretching test

▼ Xinhai wear-resistant rubber wearing test

3 Room temperature and high frequency sulfide, excellent performance guarantee

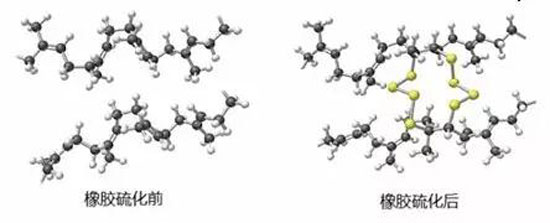

Sulfide was a net structure that people add a certain amount of vulcanizing agent to semi-finished products that was made of crude rubber, then the linear molecule of crude rubber connected with each other through "sulfur bridge" in a certain temperature, thus increased the elasticity of rubber.

It was difficult to guarantee the compound blank heated evenly in traditional heating mode, especially the large size products, its external heat was more than internal heat, which resulted external rubber in "over-sulphur", and internal rubber in "lack of sulfur". Uneven sulfuration seriously affected the overall performance of rubber products.

Room temperature and high frequency sulfide of Xinhai wear-resistant rubber products adopted the high frequency induction heating technology, let rubber heated inside and outside simultaneously and sulfured synchronously, which not only shortened sulfur time, but also made the sulfur quality more uniform, the overall wear-resisting effect was more remarkable.

The application of Xinhai wear-resistant rubber

■ Slurry pump - ultra-light rubber impeller, energy saving and consumption reducing, wet parts of slurry pump, extend equipment life

■ Valve - high elastic rubber valve liner, gate valves are tightly combined, strong sealing and long operating life

■ Cyclone - inner lining Xinhai wear-resistant rubber, extend equipment life more than one time

The wear-resistant rubber that embedded in the feeding inlet of hydraulic cyclone greatly reduced the equipment wear when the material flow.

The application of Xinhai wear-resistant rubber in slurry pump impeller

Honor of Xinhai wear-resistant rubber

Xinhai wear-resisting rubber is widely recognized by its unique rubber process. On September 28, 2013, the research appraisal about this technology was held in Yantai economic and technological development zone. After assessed by China Rubber Industry Association and Shandong Science and Technology Agency, Xinhai wear-resistant rubber performance reached the international advanced level among similar products, the wear-resisting performance was in the international leading level.

In addition, Xinhai wear-resistant rubber series also won the second prize of invention patent in Yantai in 2015.

The patent certificate of Yantai

With several decades of experience in mineral production, Xinhai has applied wear-resistant rubber into the mineral processing equipment perfectly in every wear link. According to its actual application, Xinhai configured different function models of wear-resisting rubber lining, which made the wear-resisting equipment more durable and convenient, and greatly saved operation and maintenance costs in mineral processing production for customers.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.