Based on client needs, Xinhai provides comprehensive operation management services for mine projects, Beneficiation Plants, and Tailings Storage after construction completion, including Production Operation Management, Equipment Operation Management, Safety Operation Management, Environmental Operation Management, Human Resource Management, and Financial Management. Additionally, Xinhai has established comprehensive Global Mine Service Centers according to regional needs, offering Testing and Technical Consulting, Production Materials, Spare Parts and Mine Consumables, After-Sales, and Project Expansion Services.

Xinhai professional mine operation management team possesses strong capabilities and extensive experience, providing comprehensive mine management services for clients lacking mine operation experience and offering optimization suggestions and implementation plans for mine projects with existing but unsatisfactory operation teams, helping improve operation indicators.

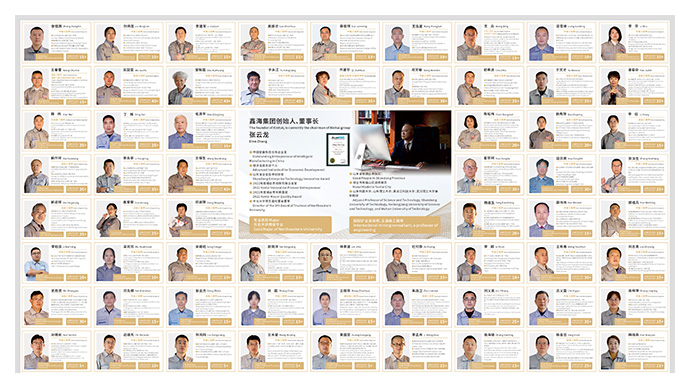

Xinhai has over 300 technical personnel, whose extensive influence and strong connections in the mine industry enable the rapid formation of a qualified mine project operation management team that complies with national requirements.

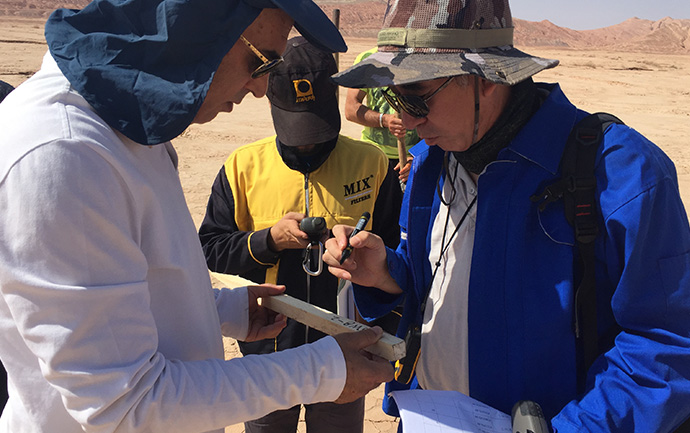

Xinhai has many years of experience in mine production operation management, with a deep understanding and rich practical experience in all aspects of mine production operation. Globally, Xinhai has participated in the construction, operation, and management of numerous mines, including domestic projects like Gansu Gold Mine, Yantai Non-Metallic Mine, Inner Mongolia Fluorite Mine, and Fujian Sulfur Iron Mine; and international projects like Zimbabwe Gold Mine and Lithium Mine, Guinea Gold Mine, Ghana Gold Mine, Mongolia Iron Mine, and Vietnam Iron Mine.

Xinhai mine production operation management and service cooperation models are highly flexible and negotiable. Recognizing the uniqueness of each mine project, Xinhai offers a series of diversified cooperation models to meet the actual needs of various mine projects and specific client requirements:

Production output, technical indicators, and cost EPC+M+O services;

Profit-sharing management mode based on production output, technical indicators, and cost indicators;

Cooperation models determined through mutual agreement.

Leveraging rich experience and strong management capabilities, Xinhai can develop scientifically rigorous and equitable performance appraisal methods for each mining operation management project team, fully tapping into and mobilizing the team’s initiative while providing motivation. Assessment indicators include ore processing volume, concentrate output, equipment operation rate, concentrate grade, tailings grade, recovery rate, etc. Additionally, Xinhai can conduct scientific, detailed, and actionable assessments of the management effects of each operation management project.

Xinhai adopts a 'cost + index rewards and penalties' approach for mine management. Whether managed by the client or Xinhai itself, the cost remains roughly the same, with the main benefits derived from index rewards and penalties. Through continuous on-site process inspections, equipment diagnosis, management supervision, technical improvements, and operation condition enhancements, Xinhai aims to identify and resolve issues, reduce enterprise costs, improve processing capacity, technical indicators, and operation rates, ensuring all parties benefit from the enhanced management. This method equates to 'incremental profit sharing,' where Xinhai receives a small portion of the 'incremental portion,' while the client receives the majority. Hence, the more the increase, the greater the benefits. This approach motivates Xinhai operation team to improve management efficiency and allows clients to gain greater benefits.

Xinhai brings together a professional and comprehensive technical team, covering the entire process of mine development and operation, possessing strong capabilities and strength to provide Mine EPC+M+O services. Therefore, the success of each mine operation management project is not only due to the efforts of the operation management team but also the collaborative efforts of Xinhai entire technical and support team.

By integrating advanced technology and management models, Xinhai can enhance the efficiency and economic benefits of mine production operations, promote the rational utilization of resources, and protect the environment, driving mine enterprises toward sustainable development. Xinhai is dedicated to identifying and improving the shortcomings of mine operations, deeply tapping potential, and enhancing technology to optimize operational outcomes. Additionally, Xinhai actively explores and introduces new technologies and management concepts to maintain a leading position in a constantly changing market environment, providing clients with more efficient and environmentally friendly mine operation solutions.

In the Zimbabwe 2 MTPA Lithium EPC project, Xinhai provided comprehensive management services throughout the project construction period, from preliminary planning to design, procurement, construction, and commissioning, ensuring the project was completed on time, with quality and quantity.

This project is an EPC project for a processing plant, involving design, equipment supply, construction, and installation and commissioning, covering many professional and coordination matters. At each stage, Xinhai strictly controlled quality, progress, and cost. The design phase involved scheme comparison and analysis conclusions; equipment manufacturing involved selecting quality supporting manufacturers and strictly controlling quality; construction teams with similar project performance were chosen; the installation and commissioning stages had pre-planned schemes, executed strictly according to plans, ultimately ensuring the smooth completion of the general contracting project.

In the Guinea 3000 TPD Gold Carbon-In-Pulp Plant project operation, Xinhai was responsible for EPC services, including 3000 t/d Carbon-In-Pulp Plant Construction Drawing Design, auxiliary facility design within the processing plant, covering Mineral Processing Technology, General Layout, Water Supply and Drainage, Dust Reduction, Ventilation, Automation, and Civil Engineering management and operation.

Xinhai technical management team conducted various technical management services according to client requirements, including completing the production process commissioning and trial production; achieving production technical indicators that basically met the process design indicators; late-stage production indicators aim for stable operation; complete the construction of the mineral processing laboratory and laboratory to meet technical requirements and put them into use; assign and staff production personnel in the mineral processing plant; conduct position training; establish safety management systems and production position equipment operating procedures; formulate monthly production technical plans and maintenance plans; annual major maintenance plans; next year's technical plans; conduct production statistical analysis; continuously summarize issues in production operations; improve production technology and management levels; evaluate the late-stage production construction plan for mine projects and make necessary preliminary preparations.

Xinhai successfully undertook the mining and excavation project of the Inner Mongolia Fluorite Mine, with both infrastructure construction and mining engineering conducted under an EPC General Contracting model.

Mining infrastructure construction covered a series of key systems, including Development Systems, Ventilation Systems, Air Supply Systems, Power Supply (including Communication) Systems, Hoisting and Transport Systems, Water Supply and Drainage Systems, and other necessary Safety and Environmental Protection Measures Systems. The construction and operation of these systems adhere to strict Engineering Standards and Environmental Protection Standards to ensure the safety and environmental protection of the mine.

Mining engineering included Mining Preparation Engineering, Cutting Engineering, Ore Pass Engineering, and Stoping Engineering. The implementation of these projects follows scientific mining principles and methods to achieve efficient utilization of mineral resources.