Thickening and sedimentation is an important part of the mineral processing plant. With the improvement of processing requirements, the traditional thickener has obvious problems, such as slow settling speed, easy to be muddy, low processing capacity, etc. According to the above problems, Xinhai keeps improving thickener, combining with processing technology, improving sedimentation efficiency, reducing muddy probability, and reducing equipment operation cost.

Xinhai Mining focuses on thickener design and research for over 20 years, acquiring numerous technical achievements and keeping multiple patents. Xinhai Mechanical Design Research Institute has rich mine mechanical design experiences and a large number of engineers with mechanical design and processing practical experience. They have the equipment research and development, design, improvement tasks on their shoulders. Therefore, a large number of innovative equipment with Xinhai characteristic born and providing more high-efficiency and energy-saving mineral processing equipment for global mines. Xinhai has two production plants, with over 200 skilled manufacturing technicians of mineral processing equipment. It can customize thickener and its corollary equipment according to the requirement of clients.

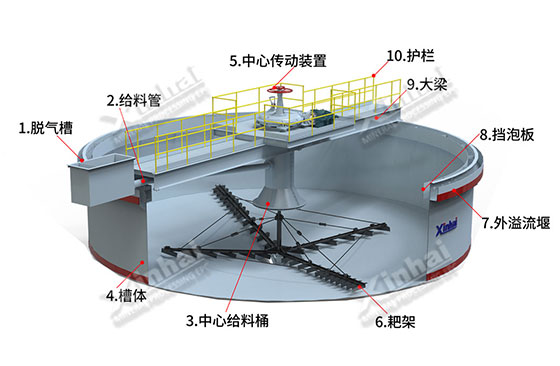

After the bubbles in the pulp enter thickener, it breaks the interface between pulp and clear water layer, which is a disadvantage for the particle sedimentation. Therefore, the bubbles should be got rid of. A high-efficiency degassing tank or defoaming tube can be matched with Xinhai thickener according to the requirement, in order to satisfy the requirement of clients and the change of ore supply conditions.

Configuration one: Using a high-efficiency degassing tank, which is used with a traditional thickener or small model thickener.

Configuration two: Using Xinhai newly developed defoaming tube. It divides the cylinder into different separation chambers, which is easy to process and used with a hydraulic thickener or large type thickener. It can also use other type thickeners.

For traditional ordinary thickener, the pulp to be concentrated is pumped into thickener. The negative pressure in the clarification zone leads to aeration, which is a disadvantage for the full sedimentation of pulp. Xinhai moves the feeding pipe under the overflow layer. Single or double pipes enter the center mixing cylinder, to avoid aeration again. The dosing pipe for multiple-point addition is used for precision dosing, with a high reagent using rate.

The feeding cylinder of traditional thickener is direct to the thickener. The pulp into the sedimentation area, it is easy to rush the particles just settled, which causes turbidity in a clear area. Xinhai high-efficiency feeding device adds a receiving tray under the feeding pipe. It can make sure the feeding pulp drops average and slow, effectively avoiding turbidity and increasing the thickening efficiency.

Besides, Xinhai high-efficiency feeding device can have special designs of concentration self-dilution and self-stable feeding hole. The pulp concentration reacted with reagents is able to automatically dilute and not change with the feeding concentration. The concentration self-stable effect makes sure that pulp can form flocculating constituent rapidly and the flocculating constituent is not easy to be broken.

According to different sizes and capacities, Xinhai thickener can be deployed with three different tanks: ordinary tank, deep cone tank and box tank.

Configuration one: for ordinary tank thickener, Xinhai updates the overflow dam into a zigzag shape to resolve the negative pressure difference in the thickener. The large negative pressure is resolved into some small pressure differences, which improves the local drainage suction phenomenon caused by non-horizontal overflow dam. At the same time, inner overflow dam is added, the material flows through a prescribed itinerary, increasing the particle travel and the space of the settlement zone and avoiding the “short-way” phenomenon. Besides, the bubble baffle is added to the inner side of the outside overflow dam, which divides the liquid in the tank into three individual parts, increasing the particle travel, reducing the suspension time, and advantage for the particle sedimentation.

Configuration two: Xinhai deep cone thickener is a new type high-efficiency deep cone thickener with flocculation settlement theory, shallow subsidence theory, and deep compression theory. The bottom cone angle is large and the cylindrical section is high. The volume of storage slurry is large. long slurry compression time. It needs to be used with a flocculating agent. A higher underflow concentration can be gained. It is suitable for fine or superfine material, with large capacity. The concentration efficiency is high and less occupied area. Compared with traditional thickening or two-stage filtering, the deep cone thickener improved 30%, but the operation cost reduces about 40%.

Configuration three: the box tank is wildly used for the concentration box. Through adding the tilt board, the top pool area of the box tank can be used at the largest usage, and improving the capacity of the unit area in a further way.

According to the requirement of clients, Xinhai mining can deploy a mechanical transmission device or hydraulic transmission device.

Configuration one: mechanical transmission device uses motor driving reducer. The transmission is more complex than hydraulic transmission. It can be divided into the manual rake and electric rake. The electric rake is controlled by PLC automatic control. It also deploys an overload protection device, which can prevent thickener overload work.

Configuration two: hydraulic transmission device uses a hydraulic motor instead of electric transmission. The hydraulic station provides motive power as a transmission device. The oil pump of the hydraulic stations is a variable pump. Through adjusting the oil displacement of the oil pump, the rake rotates speed can be adjusted to reach a good technology effect. Under the same power, the volume and weight of the hydraulic transmission device can reduce a lot. Automatic control can be realized easily, and reducing operating costs.

Xinhai Mining changes the rake tooth line type form diagonal into curvilinear. Therefore, the slurry can be raked to the center, and give a force toward the center, which is an advantage to squeeze out part of the water from the slurry and increase the underflow concentration. It also increases the capacity of thickener. According to different tanks, Xinhai Mining can deploy different rake structures.

Configuration one: line type rake. it is usually used with shallow through body thickener, and suitable for small diameter thickener.

Configuration two: girder structure rake. The girder structure improves the structure strength and stability. It is suitable for a larger diameter tank (it is suggested to be used for 18m).

In normal operation, it is sure that there is mud on the plate. The thickness of the mud layer is different along with the particle size composition and viscosity, forming a dynamic balance thickness. Xinhai Mining researched a lot on the structural principle and material of tilt plate thickener. Therefore, Xinhai makes slurry flow accord with fluid mechanics. Therefore, the mud can easily expel. The working principle of the tilt plate module is shallow subsidence theory, which is reducing settlement distance, time and improve the production capacity of a single occupied area. It is suitable for the small occupied area and large capacity, or indoor configuration places requiring insulation.

Besides, Xinhai Mining can deploy steel structure for thickener, which is suitable for equipment modularization and easy to transportation and installation.

1.Guinea 6000tpd gold processing plant

2.Henan 3000tpd gold processing plant

3.Shandong 1300tpd molybdenum processing plant

4.Tanzania 1200tpd gold processing plant

5.Gansu 1000tpd gold processing plant

6.Malaysia 700tpd gold processing plant

7.Zimbabwe 700tpd gold processing plant

8.Morocco 500tpd silver processing plant

Processing plant equipment is the key to realizing processing technology and economic index. In the future, Xinhai Mining will insist on technological innovation and equipment quality, with the strong technical strength as the core competition, good quality equipment as the quality guarantee, devoting to customize reasonable processing flow for global mines, and building solution and equipment with ideal efficiency.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.