As one of the common processing equipment for metal and non-metal minerals, agitating flotation cells can be divided into mechanically agitating flotation cells and air-inflation agitating flotation cells. The working principle of them is that: driven by the motor through the triangular belt, the impeller rotates to form the suction (or external inflation) of negative pressure slurry, so that the air, medicine, and slurry mix, minerals adhere to the bubble surface and float up, forming a mineralized foam layer on the slurry surface, under the condition of relatively constant control of the liquid level, the foam is scraped out with a scrape.

As the main equipment of the flotation plant, the number of flotation cells used is large and the operation time is long. Therefore, it needs to operate in the right way and regular maintenance and repair to extend the usage period and keep the operation of the flotation cells stable and continuously.

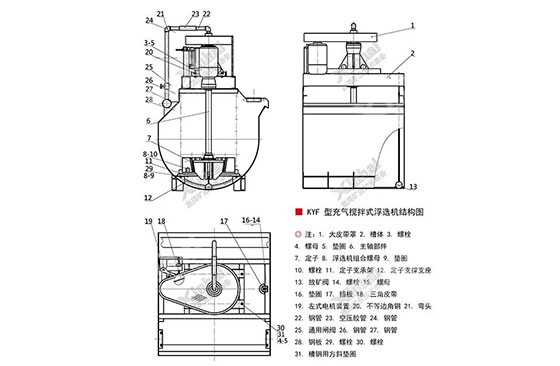

Different types and models of flotation machines have differences in structure. However, a flotation machine usually includes the motor, bearing, scraper, center cylinder, cell body, steady flow plate, nozzle, impeller, suction pipe, and other devices. The flotation machine maintenance personnel and operators must be familiar with the structural parameters of each type and type of flotation machine according to the actual situation of the plant, in order to ensure that problems can be found in time to avoid the impact of economic benefits.

During the operation of flotation machines, the operators must finish the attentions before the operation, launching, and stopping. Strictly follow the operating rules of flotation machine, in order to give full play to the role of flotation machine, improve production and use efficiency, create more benefits.

1. The attentions before the operation

Before the operation, it is necessary to check whether there is any debris in the flotation tank to prevent debris from blocking the impeller or blocking the circulation hole and channel. If necessary, the mine gate should be opened to flush.

Check the mine gate and level control device whether flexible or not. Whether the ore drainage can be adjusted according to the requirements of classification to maintain a relatively constant grout level;

Check the scraper of flotation machine, driving triangle belt and box lining, keep it smooth and tidy, check whether the false bottom, flow stabilizer plate and baffle are complete and set smoothly;

Check whether the air pipeline of the flotation machine is smooth and dredge in time if any problem is found.

Check whether the lubricator of the flotation machine is filled with lubricating oil and whether the bearing is filled with grease;

Check whether the device fasteners are loose;

Check the pulley shaft rotation is flexible, impeller cover clearance is appropriate.

2.The attentions during launching

There are two kinds of situations, one is empty slot launching, the other is full tank launching after stop. The operation orders of the two situations are different.

When the empty tank launching, the ore should be fed first, the stirring tank should be started, then the flotation machine connected with the feeding tank should be started, and the flotation machine connected with it should be started after the pulp has completely submerged the cover plate;

After stopping, when the full tank launching, it shall start from the last tank to the previous tank one by one according to the flow direction of the slurry. It shall start after manually turning each flotation cell until the impeller can rotate more flexibly, and then start the stirring tank.

3.The attentions during stopping

The situation of stopping is similar to launching. It can be divided into drain pulp stop and stop keeping the parking tank full.

When discharging slurry stops, stop feeding first, and then open the middle stern box gate according to the opposite direction of slurry flow. Stop the flotation machine until the liquid level drops to the point where the cover plate can be seen.

The steps are relatively simple when stopping at a full tank. Stop feeding first, and then stop stirring tank according to the flow direction of slurry. Stop the flotation machine successively from the first tank of the flotation machine.

In the initial working stage, the new flotation machine should strengthen the detection frequency, measure the motor and spindle temperature regularly, observe whether there is an abnormal sound, and deal with the problem in time. The daily inspection of flotation cells should be equipped with professional personnel familiar with the operation of flotation machine, usually every 3-4 months should be a thorough inspection, including impeller cover clearance, impeller wear, bearing clearance, whether the pipeline is smooth, slot and whether the pipeline leakage. For vulnerable parts to ensure that the warehouse reserves, once damaged can be replaced in time.

The flotation cell daily check attentions includes:

Whether the bolts are loose, whether the triangle belt is complete, whether the safety cover is complete and firm;

Whether the temperature of motor and spindle bearing is normal;

Whether the inspiratory capacity is normal;

Whether each lubrication point is kept lubricated, whether the lubricating oil is sufficient;

Whether the ore drawing valve and the box are kept straight;

Whether the tank is leaking ore;

Whether the scraper parts are in good condition.

Above are the attentions of flotation cells daily operation and maintenance. For flotation plant, on the one hand, suggest looking for mill plant overall aptitude equipment manufacturers buy flotation machine. On the other hand suggested flotation machine operating and maintenance personnel improve their operation skills, pay more attention to the flotation machine running, encounter problems after calm analysis reasons and take corresponding measures, timely response to the flotation machine all kinds of conditions, to ensure that the flotation operation smoothly, avoids unnecessary economic losses.

1.Yunnan 4400tpd copper processing project

2.Pakistan 1500tpd copper processing project

3.Mexico 1500tpd Cu-Pb-Zn-Au multiple metal processing project

4.Shandong 1300tpd molybdenum tungsten processing peoject

5.Vietnam 800tpd graphite processing project

6.Uganda 720tpd phosphate processing project

7.Morocco 500tpd silver processing project

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.