The efficiency of modern mining corporation profit from the leading mineral processing technology, while the leading mineral processing reflected in customized and reasonable processing flow and high-quality mineral processing equipment. The effort of mineral processing efficiency can’t leave the processing technology design and the energy-saving mineral processing equipment. Since its foundation in 1997, Xinhai Mining always pays attention to technology creation. It insists that there isn’t the same mine in the world. Every mine should customized their own mineral processing technology and equipment to create ideal efficiency.

In the innovation of equipment, Xinhai Mining Machinery Design Institute has rich mineral machinery design experience and a lot of technics with mineral machinery design experience and mineral processing experience. It holds the tasks of equipment research and development, design, innovation and so on. It has already improved over 80% common mine equipment in technology and applied for a number of patents. It can provide high-efficiency and energy-saving mineral processing equipment for all mines in the world. Many innovation equipment is created here with Xinhai feature.

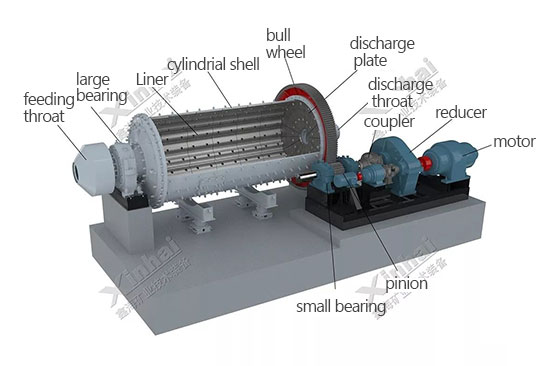

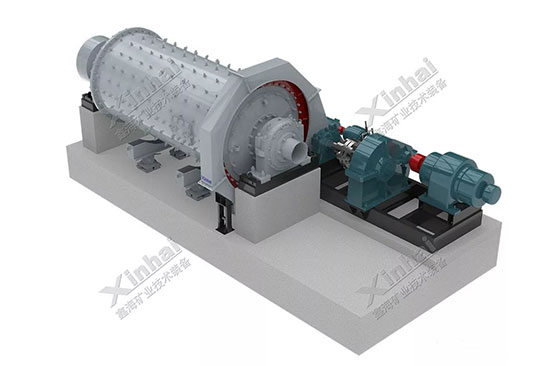

Xinhai focuses on the research and development of ball mill for 20 years, and achieved a lot in ball mill research and development. It can provide customized ball mill equipment by the requirement and the size of ball mill, including drive system, jacking device, feeding device, large and small gear mist spray lubrication system, antifriction bearing, whole rack. Realizing the goal energy-saving, low-consumption, and high-efficiency in this way.

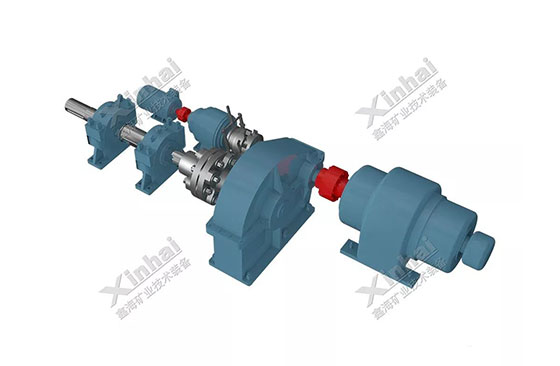

1. Drive system with low-speed driving device

During the overhaul of ball mill, the low-speed driving motor starts first, meshing jaw coupling reduces speed though reducer and gears. In this period the rotation speed is 0.1RPM. In this period, overhaul and liner replacement can be done. If the ball mill closes down over 4 hours, the material in ball mill agglorates when it is hard to start it. Low-speed driving device can jig the ball mill before the major motor starts. It is advantage for the check and start of ball mill.

2. Hydraulic jack device

When the ball mill maintenance, only the handle of the hydraulic station can make the hydraulic jack up and down, the ball mill cylinder jacked after the big gear and pinion off, easy to replace the pinion, maintenance gear transmission part, grinding machine bearing part, replace damaged bearing parts.

3. Multiple feeding device choices

For the feeding device of ball mill, Xinhai Mining designs drum feeder, combined feeder, and feeding dolly. The three types of devices, especially the feeding dolly for large ball mill or meeting the demands, the feeding pipe is fixed on the mobile dolly, which can move through the track front or after. The feeding pipe can plug in the feeding throat of ball mill, and the connecting flange can connect with the feeding device. When repairing the ball mill, the dolly can be moved away through track.

4. Large and small rack spay mist lubrication system

The Spray mist lubrication system is deployed by Xinhai Mining for ball mill. The dry oil atomizer periodically ejects a certain amount of grease onto the working surface of the gear to achieve lubrication and reduce gear wear. In addition, the spray lubrication system adopts visual PLC control, which can maintain basic parameters, control the amount of oil injection each time and display the working process.

5. Antifriction bearing instead of sliding bearing

Xinhai Mining ball mill uses double row cylindrical rolling bearing instead of sliding bearing. Rolling bearing is linear contact, friction is far less than the surface contact sliding bearing, the power consumption, and installation requirements are also lower than sliding bearing. At the same time, the rolling bearing lubrication requirements are low, no pressure is required for oil supply, only the oil cup break can meet the requirements for normal operation of the ball mill.

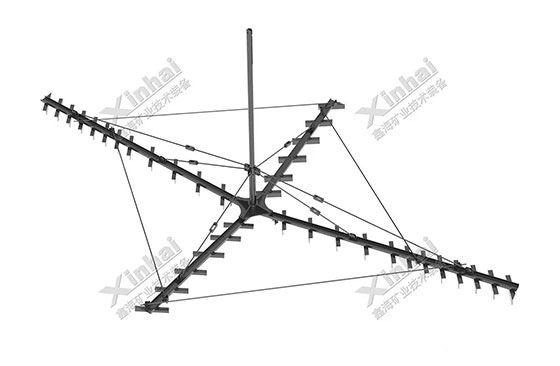

6. The whole frame rake

For middle and small ball mills, Xinhai Mining applies the whole frame rake. The whole mill is mounted on an integral welding frame connected with the foundation. All parts of the equipment on the overall frame, the whole equipment in the factory had already finished installation and debugging, to the scene just to play good in advance, on the basis of looking for a good level and can be installed firmly, installation and convenient operation, greatly reduce the amount of the installation, shortening the time limit for a project, but also conducive to the long-distance transportation of the equipment.

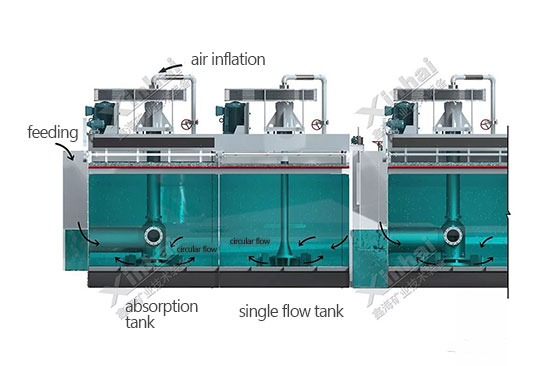

KYF flotation machine and XCF flotation machine are two common flotation equipment in concentrator. For the new plant, the KYF flotation cell requires a difference of 300-500mm in height between the operations, which increases the cost of infrastructure construction. For the transformation of the old plant, the application of KYF flotation cell is restricted to a large extent because the height of the concentrator and the height difference of the process have been fixed. In this case, Xinhai Mining applies the combination of KYF flotation cell and XCF flotation cell. It solves the problem of ladder configuration of KYF flotation cell, saves the consumption of foam pump, reduces the operation of equipment management and maintenance, so as to reduce the investment cost, improve the efficiency of mineral processing, and achieve the effect of 1+1>2.

1. Flat device, reducing the basis investment

According to the general requirements of the selection plant, the use of KYF flotation machine for coarse selection, sweeping selection and selection operations requires about 5 steps, which requires an increase of 2m height difference and is bound to increase infrastructure investment. While Xinhai Mining choice the combination of KYF flotation cell and XCF flotation cell in flat device, which effectively reduces the basis investment

2. Reducing the energy consumption, and reducing the equipment damage

The energy consumption of KYF flotation cell is low, but the participation of foam pump increases the energy consumption of flotation operation. When the KYF flotation machine is used alone, the foam pump equipped with the ladder configuration needs to be equipped when the mine returns, with high rotating speed, large linear speed, fast wear of impeller and pump shell, and the wear degree is 3-6 times that of the flotation machine. Xinhai Mining KYF and XCF combined flotation cell saves the foam pumps, which improved the operability of processing plant, and reduces energy over 20%, and avoiding the shortcomes of foam pumps at the same time.

3. Special structure, improving the processing effect

The KYF and XCF flotation cell are both U shape fracture surface. However, the KYF flotation machine has no upper blade suction pulp, while the XCF flotation machine has upper blade suction pulp. The combined unit formed by XCF flotation cell and KYF flotation cell in Xinhai Mining uses the blade of XCF flotation machine to complete the suction feeding of ore and medium ore operations, which greatly improves the overall ore processing efficiency. Besides, Xinhai Mining KYF and XCF flotation cell can be designed into single - wall backward sloping blade design, which improves the connect surface of impeller and pulp. Strong mixing ability can be formed under the condition of low rotation speed, so as to promote the dispersion of pulp, improve the restart ability and reduce the degree of "turning over".

In the early stage, traditional thickener was mostly used in concentrator. However, with the continuous improvement of ore dressing requirements, the disadvantages of traditional thickener are also increasingly prominent, such as slow settling speed, easy to run and muddy, low processing capacity. Focus on these problems, Xinhai Mining develops the updated high-efficiency thickener, which has obvious advantages from traditional thickener.

1. Add the feed pipe under the liquid level

For the conventional ordinary thickener, the slurry to be concentrated is usually pumped into the thickener, which is easy to generate negative pressure in the clarification zone and lead to air mixing, which is not conducive to the full sedimentation of the slurry. The inlet of the feed pipe of Xinhai updated high-efficiency thickener will be set below the overflow surface of the thickener, and the single or double pipe will enter the central mixing cylinder of the thickener to avoid the mixing of secondary air.

2. Move the feeding cylinder down

The conventional thickener feeding barrel is usually located at the junction of settling zone and settling zone, which is easy to muddy the materials in settling zone again. Xinhai Updated high-efficiency thickener moved the feeding cylinder down, and there are a plate to keep the material. It makes the feed pulp fall down more evenly and slowly, so as to effectively prevent the flowage phenomenon caused by the ore pressure, and the settlement effect is better.

3. Add deaerating tank

After the bubble in the pulp enters the concentrator, it will destroy the interface between the pulp and the clean water layer, which is not conducive to the sedimentation of particles, so it should be removed in advance. Xinhai updated high-efficiency thickener can deploy ordinary deaerating tank, high-efficiency deaerating tank and defoaming cylinder. The purpose is to eliminate the bubbles in the pulp and let the solid particles settle quickly.

4. Add inner over dam

Xinhai Mining adds inner overflow dam for thickener, so that the material can flow through the regulation routine. By increasing particle stroke and preventing "short circuit", the settlement area is greatly increased and the clarification area is not affected.

5. Add Zigzag overflow dam

Xinhai Mining adds zigzag overflow dam is mainly to resolve the negative pressure difference in the thickener. The large pressure difference is changed into countless small pressure difference, which can improve the suction phenomenon of local drainage caused by uneven overflow dam.

6. The shape of rake from line type to curve type

Xinhai Mining change the shape of rake from line type to curve type. In this way, the pulp is not only harrow to the center, but also gives the force of the extruded center, which makes the bottom flow concentration higher, which increases the processing ability of the thick-driven machine.

Mineral processing equipment is the key point of realizing mineral processing technology and economy index. The technics from Xinhai Mining Mechanical Design Institute can provide complete mineral processing equipment for clients according to the equipment requirement from Mineral processing research institute and Mine Design Institute. Clients can enjoy the one packaged service including mineral processing experiment, mineral processing technology, equipment selection, mine design, equipment customization and other service. The service can be related with mineral processing technology, improving productivity and reducing the energy, and lengthening the stable running period.

In the future, Xinhai Mining will consist the technology innovation and the quality of equipment at the same time. Based on the powerful technical strength, the quality of the ore selection equipment is the quality guarantee. Strive to tailor the reasonable process technology for the global mining, create the ideal choice factory landing plan and the factory equipment!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.