Mining slurry pump is a kind of mineral processing equipment which increases the energy of solid and liquid mixed medium by centrifugal force (the impeller of slurry pump rotates). In the concentrator, the slurry pump is mainly responsible for slurry transportation, feeding, pressurization, emission, etc., and its investment cost accounts for a significant proportion in the infrastructure investment of the concentrator and later production and maintenance costs.

In the production, due to the transport medium of the mining slurry pump generally contains solid particles, and the fluid particles erosion, medium corrosion, cavitation, etc., the wear speed of wet part is very fast, the service life is generally short. Therefore, how to improve the wear resistance of the wet part and reduce the investment cost has been an urgent problem for concentrators.

In order to solve this problem, Shandong Xinhai Mining Technology & Equipment Inc (Xinhai Mining for short) successfully developed a new type of rubber pump series product - XPAⅡ type high lift wear-resisting rubber slurry pump (XPAⅡ type slurry pump for short), and obtained the national utility model patent (CN201020575068.X a high-lift rubber pump), it completely solved the problems of anticorrosion but abrasion-resisting of the stainless steel pump, wear-resisting but anticorrosion free of alloy pump and low-head of single-stage rubber pump, which expanded the application field of the rubber pump.

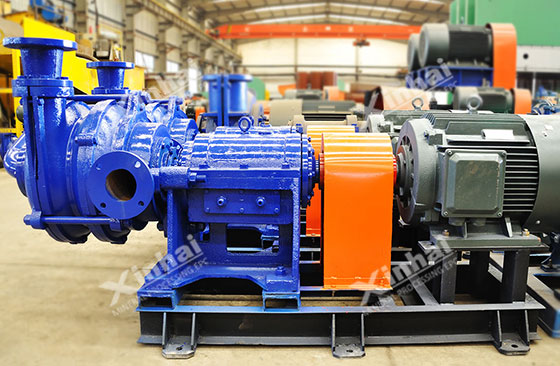

(Xinhai Mining- XPAⅡ type high lift wear-resisting rubber slurry pump)

(The patent of XPAⅡ type high lift wear-resisting rubber slurry pump)

XPAⅡ type high lift wear-resisting rubber slurry pump was a special new type of rubber slurry pump performance developed by Xinhai Mining.

On the basis of single-stage centrifugal pump, XPAⅡ type slurry pump obtains the steep dipping head-flow curve under the principle of the steady flow and head superposition of pumps in series. After the slurry is output by the impeller of the first pump chamber, it immediately enters the impeller of the second pump chamber and continues to be pressurized, so as to obtain a higher head.

In addition, XPAⅡ type slurry pump adopts the radial feeding, making the pressure of sealing box approximately equivalent to the pressure of impeller inlet pressure, so there is no leakage in the slurry pump. XPAⅡ type slurry pump is particularly suitable for the feeding of filter press, and can meet the feeding operations of the filter press below 1000m2.

After the continuous improvement by the technicians, Xinhai Mining successfully applied for and obtained two utility model patents: CN201721111489.5, a slurry pump device to prevent the leakage of the shaft seal, and CN201721109424.7, a feed box of slurry pump.

CN201721111489.5 A slurry pump device to prevent the leakage of shaft seal

CN201721109424.7 A feed box of slurry pump

1. Double-stage pump design, the head reaches 75 meters

Double-stage pump series design, and don't need to increase the impeller diameter, which breaks through the limitation that the head of the rubber pump is not high, the head can be up to 75 meters, equivalent to the head provided by two conventional rubber pump series.

2. Wear-resistant rubber lining part, long service life and less faults

The impeller and sheath of XPAⅡ type slurry pump are lined with Xinhai Mining high wear-resisting rubber, and its service life is twice as long as the metal pump. The wear-resistant rubber has the advantages of the high elasticity, easy to resist material impact and abrasion, so the failure rate is low and it is easy to replace. The overall maintenance cost is reduced by about 60%.

3. A small proportion of rubber lining part, energy-saving and cost-reducing

The proportion of sheath and impeller is smaller than metal (the wear-resisting rubber is 0.97 generally, the metal is 7.85 generally), so the required power is smaller than the metal lining part. In practical application, the total energy consumption can be reduced by 30%.

4. 100% shaft seal, no leakage

A significant characteristic of XPAⅡ type slurry pump is suction feeding, which makes the pump at work without leakage; At the same time, XPAⅡ type slurry pump adopts packing seal, and makes the high elasticity of wear-resistant rubber lining part to enhance its sealing performance and ensuring the zero leakage of the slurry pump.

As a new rubber pump independently developed by Xinhai Mining, XPAⅡ type slurry pump is widely used in the field of mine, electric power, metallurgy, coal, environmental protection with its high efficiency, anticorrosive and wear-resisting, long service life and low investment cost.

Taking a gold ore tailings dry discharge transformation project in Shanxi undertaken by Xinhai Mining as an example, the client once purchased a batch of XPA wear-resistant slurry pumps from Xinhai Mining, the slurry pump operated normally, and never changes the parts. Thanks to the first cooperation, the client unhesitatingly chose Xinhai Mining again.

Project overview:

The flow was 60m3/h, the vertical height difference was52m, and the pipe length was 474m, the diameter of the polyethylene pipe was 117mm. The flotation tailings were divided into two parts: one part was sent to underground filling by the slurry pump and hydrocyclone, the hydrocyclone overflow and the rest of tailings were sent to tailings dry stacking.

Xinhai solution:

Before: The workshop of tailings dry stacking was located near the mineral processing plant, the material after the tailings dry stacking was sent to the tailings dam by the three belt conveyors.

After: This project adopted XPAⅡ-65 high lift rubber pump, the slurry was transported to the workshop of tailings dry stacking with 55 kW electric motor power, the water returned to the mineral processing plant, and the dry material was discharged to the tailings pond.

(Operation site of XPAⅡ type slurry pump)

Project result:

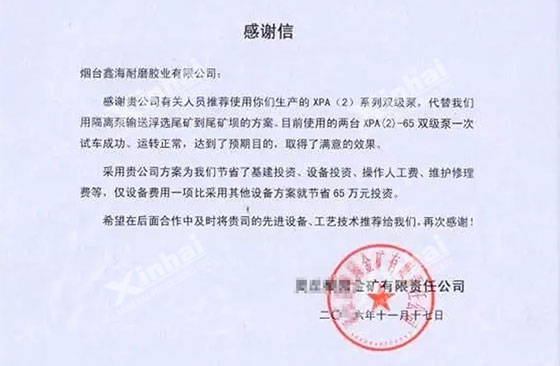

The trial run succeeded, and the customer sent a thank-you letter. By the comparison, only equipment investment saved more 650,000 yuan than other equipment schemes, and the operation cost even saved 35%.

(Thank-you letter sent from the client)

As the service concept of "What you need is what we can do", Xinhai Mining always takes the independent innovation as a driving force for the enterprise development, thinks what customers want, provides what customer needs, and strives for each product, every tiny component can create a powerful productivity with a low investment cost, resolves the customer problems in practical production, and helps the customers to obtain the ideal investment returns.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.