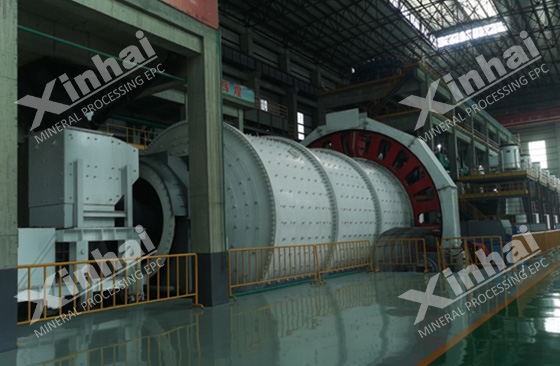

Xinhai is a large ball mill manufacturer in mineral processing equipment, who can produce various types of grinding equipment, including dry ball mill.

This ball mill is the horizontal type with two warehouses. The material is sent evenly into the first warehouse of ball mill from the feeding end, the ball mill contains stepped liner or corrugated liner, steel ball. As the rotation of the cylinder, the steel ball raises to a certain level and then fall down under the action of centrifugal force, which achieves the coarse grinding under the steel ball hit and the self-grinding. Then, the material enters into the second warehouse of ball mill, where is equipped with flat liner and steel ball. The material can be crushed again by the action of the steel ball. Due to the continuous material feeding, the material moved to the discharge end continuously under the pressure and complete the grinding stage.

The structure of dry ball mill is composed of feeding port, discharging port, rotary part and transmission part. It adopts steel-casting hollow shaft. The liner is made of the wear-resistant liner, which has good wear resistance and can be replaced, easy to repair. Besides, the dry ball mill runs smoothly and operates reliably.

Dry ball mill is an important grinding equipment to achieve separating particle sizes after crushing stage. It is widely used in the production of cement, silicate products, new building material, refractory material, black and non-ferrous metal processing. Xinhai specializes in the production of full set of mineral processing equipment with high technical content, high innovation and high efficiency, including dry ball mill,flotation machine, magnetic separator.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.