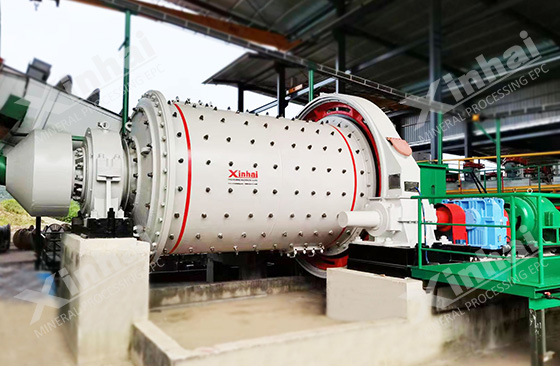

A new-type mill, cone overflow ball mills, has become more and more popular in ore dressing plants in recent years. Xinhai is one of the leading suppliers manufacturing this new-type cone overflow ball mills. Taking Xinhai's cone overflow ball mills as an example, the following gives you a brief introduction of this new-type mill.

(a) Cone Overflow Ball Mills Structure

A cone overflow ball mill consists of feeding end, cylindrical shell with the reasonable length-diameter ratio, a tapered wall with the suitable angle, a discharge end, drive system, lubrication system and other parts. Compared with traditional overflow ball mills, its biggest difference lies in the shape of the shells. Traditional overflow ball mills all have cylindrical shells, while cone overflow ball mills have been added a tapered wall near the discharge end of the cylindrical wall.

(b) Cone Overflow Ball Mills Advantages

Cone overflow ball mills are made with a tapered design in the shell wall close to the discharging end, which makes materials ground by steel balls in the tapered wall. The nearer steel balls close to the discharging end, the smaller the steel balls are. According to grinding principle, the smaller the steel balls are, the more fully the ores access steel balls, so the grinding performance is better. In other words, this tapered design strengthens traditional cone crusher's advantages and enhancing grinding outcome by getting the finer product. Besides, Xinhai replaces its cone overflow ball mills' sliding bearings with large double self-aligning roller bearing, immensely reduce friction force and thus saving energy. Xinhai also uses corrugated linings to ascend ores and enlarge the contact area between steel balls and ores, thus improving the grinding performance and reducing the energy consumption.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.