Building and running a zinc flotation plant where winter temperatures regularly hit –30 °C isn’t just about slapping on heaters or choosing cold-rated steel. Standard assumptions—slurry rheology, equipment access, safe working windows, even how many people you can productively put in one area—break down fast below –20 °C. Pumps cavitate differently, flocculant mixing slows, frost heave surprises you, and outdoor work becomes measured in hours rather than days.

This piece focuses on the practical engineering calls that determine whether a cold-region zinc plant gets built on time, starts up reliably, and keeps running through multi-month winters. We draw directly from real experience on a 1,000 t/d zinc flotation project in Mongolia to show what changes when cold stops being a line item and becomes the dominant constraint.

In extreme cold, people often talk about putting thickeners and water tanks indoors “to prevent freezing.” That’s only half the story. The bigger reason is underflow density control.

At sub-zero ambient temperatures, even short exposure of the feedwell or rake arms creates thermal gradients across the tank.

Those gradients make settling rates erratic, floc structures fragile, and underflow density swing by several percentage points day-to-night or shift-to-shift. Unstable underflow density directly hammers downstream filtration in a dry-stack tailings circuit: filter cloths blind faster, cycle times lengthen, moisture content creeps up, and you either undersize filters or run chronically overloaded.

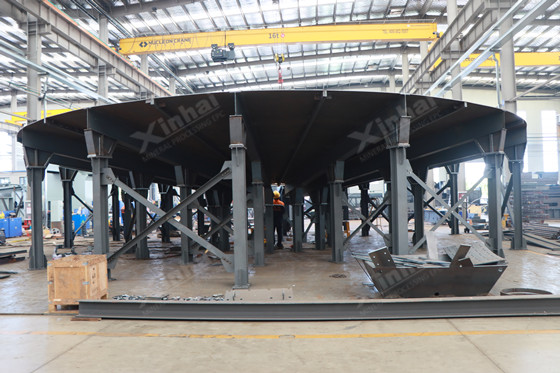

Placing 15 m and 20 m hydraulic center-drive thickeners (and the associated process water tanks) inside a heated building keeps slurry temperatures stable enough to hold underflow within a tight band. That stability lets you design pumps, piping, and filters with smaller safety margins—lower installed power, less wear, more predictable OPEX.

On the Mongolian project, this layout choice was locked in during basic engineering precisely because outdoor thickeners would have made dry stacking unreliable in winter.

A lot of people assume dry-stack performance lives or dies with the filter presses or belt filters. Field reality in cold climates is different: thickener underflow consistency is the real choke point.

Low temperatures slow particle settling, reduce flocculant adsorption kinetics, and make the pulp more thixotropic. If thickener control doesn’t compensate, you get wide swings in underflow density even when feed rate is steady.

That cyclic variation overloads filters, forces extra flocculant, and pushes cake moisture higher than design—exactly what you don’t want when you’re trying to stack material that has to stay stable at –30 °C without ponding.What matters most:

Sizing the thickener diameter using winter settling flux data (not yearly average)

Oversizing underflow pumps and lines for higher apparent viscosity

Running advanced control that holds bed level and torque to prioritize density stability over momentary throughput peaks

The Mongolia project uses high-rate/hydraulic center-drive thickeners + pressure filters + dewatering screens in series. Experience there confirms that when underflow stays consistent, the filtration circuit behaves predictably even in deep cold.

Bolted thickeners get sold on transport savings (smaller pieces, lower shipping cost). In extreme cold, the bigger win is installation risk reduction. Field-welding a 20 m diameter tank at –20 °C to –30 °C is miserable: preheat requirements go up, welder productivity drops, defect rates rise, and NDT becomes harder. Add wind, short daylight, and the need to stop for safety

whenever temperatures crash further, and you can easily lose weeks.

Bolted design shifts almost all quality-critical work (fit-up, sealing, leak testing) to the controlled factory environment. On site you’re mainly aligning, tensioning, and grouting—tasks that can continue at lower temperatures with proper procedures. Yes, it takes more field hours (our estimate was ~40 days per 20 m unit with four fitters working together), but you eliminate most weather-induced rework and NDT delays.

For the Mongolian 15 m and 20 m units, this approach let us finish tank assembly indoors during the second-phase winter work, avoiding the outdoor welding nightmare entirely.

In places like Mongolia, you get maybe 6–8 weeks of tolerable outdoor working conditions before temperatures and wind force you inside. That means installation sequencing has to be a design input, not a construction afterthought.

We split the work into two clear phases:

Phase 1 (pre-winter, Sep–Nov 2025): everything that had to happen outdoors—primary crushing, ore bins, ball mill, flotation cells, pump groups, initial piping runs, powder bins. We ramped up to 20 installers split into four crews to maximize parallel work before the –12 °C + high winds shut outdoor progress down on Nov 22.

Phase 2 (post-heating, Dec 2025 onward): thickeners, operating platforms, reagent systems, dust collection, electrical & instrumentation, remaining piping/non-standard hoppers. Heating came online end-December; we restarted with 8 people Dec 23 and built toward 14.

Modular skids, pre-welded spool sections, and lifting lugs designed for indoor crane access were decided months before steel hit site. Without that early sequencing thinking, we’d have had idle crews, congestion inside the building, or unsafe crossover with the client’s structural steel erection.

In –30 °C winters, every manual task—valve operation, sampler access, visual checks—takes longer and carries higher frostbite or slip risk. Automation isn’t primarily about pushing recovery a few points; it’s about cutting exposure hours.

On this project we included full automation for:

Crushing & screening

Grinding & classification

Flotation air, level, and reagent addition

Video monitoring + central control room displays

Fewer people outside in the dark at –35 °C means fewer incidents and steadier operation. The on-site lab (jaw crusher, vibration mill, atomic absorption, balances, etc.) closes the loop: real-time assays let operators adjust for ore changes + temperature-driven flotation kinetics shifts without waiting days for off-site results.

This 1,000 t/d zinc flotation plant + dry-stack tailings system in Mongolia demonstrates the approach works:

Thickeners and water systems indoors for slurry temperature & density stability

“Thickening + filtration” dry stacking circuit with tailored equipment (high-rate thickeners, filter presses, dewatering screens, wear-resistant pumps)

Strict seasonal phasing: outdoor Phase 1 completed before deep winter; indoor Phase 2 after heating

Automation across process units to minimize winter exposure

Bolted thickeners to control installation quality and schedule risk

The client—an existing repeat customer—chose us again after a previous 3,500 t/d iron project. That trust, plus the fact we’ve kept installing through –30 °C+ winters without major weather-related stoppages, shows these aren’t textbook ideas; they’re field-proven choices.

Cold-climate zinc flotation plants expose every shortcut in conventional warm-region design. Success comes from treating winter constraints as primary inputs—layout, equipment selection, installation logic, control strategy—not bolt-on mitigations.

When you do that, you don’t just survive the cold; you deliver a plant the operators can actually run year-round.

If you’re evaluating or building in similar conditions, start with the question: “What breaks first when it’s –30 °C?” The answer usually points you to the decisions that matter most.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.