Copper ore in nature can be divided into porphyry copper ore, sandstone type copper ore, copper-nickel sulfide type, pyrite and so on. Different types of copper ore use different mineral processing technologies. This article will introduce three different mineral processing technologies for treating single copper sulfide ore, namely: two-stage grinding + two-stage flotation process, one-stage grinding + flotation coarse concentrate regrinding process, and one-stage grinding process+flotation process.

For copper ore embedded with uneven thickness, two-stage grinding and two-stage flotation process are suitable. The two-stage grinding can further reduce the ore particle size and make most of the copper minerals reach monomer dissociation.

The specific technological process is as follows: the raw ore enters the grinding equipment and is ground to -200 mesh, so that most of the copper minerals complete the monomer dissociation. When the particle size of -200 mesh ore reaches about 80%, the ore can enter the hydrocyclone for classification, and the classified product is subjected to second-stage grinding. The product after regrinding is classified into a high-efficiency mixing tank for mixing, and then sent to the flotation machine for a rough separation after mixing evenly. The obtained concentrate is sent to the concentrate silo for storage, and the tailings are swept. After the products are stirred, they are subjected to one-stage roughing-three-stage selection-two-stage sweeping to obtain the final copper concentrate and tailings. mine.

Process characteristics: The main reason for the use of two-stage grinding is its high grinding efficiency and good effect in preventing excessive crushing of copper minerals. This

When dealing with single sulfide ore or copper-molybdenum ore of porphyry copper ore, one stage grinding + flotation rough concentrate regrinding process can be selected.

The specific process is as follows: the ore with a particle size of less than 2mm is sent to the grinding equipment for grinding, and the ore is ground to -200 mesh in the first stage of grinding. When the content reaches 40-70%, it can be sent to the flotation machine for flotation. After one-stage roughing, the obtained rough concentrate is reground, and the final copper concentrate product can be obtained after three-stage or four-stage roughing. After the coarse concentrate is ground for a second time, the particle size is finer than before. The dissociation effect of copper minerals from gangue minerals and pyrite is better, and its flotation concentrate grade is better.

The characteristics of this process: it is suitable for processing low-grade raw ore, and it is suitable for ore dressing plants with high processing capacity. This process can obtain better economic benefits.

When dealing with ores with coarse and uniform copper minerals embedded in particle size, or when copper minerals are loosely combined with gangue minerals and contact flat ores with smooth edges, a grinding-flotation process can be selected.

The specific process is as follows: the raw ore enters the grinding equipment for grinding. When the ore particle size of -200 mesh reaches 50-60%, the copper minerals basically complete the monomer dissociation. The products with qualified grinding particle size enter the spiral classifier for classification, and the unqualified products are returned to the grinding equipment through the circuit for regrinding. The graded pulp enters the mixer for mixing and stirring with the chemicals. After stirring evenly, the pulp enters the flotation machine for one-stage roughing, two-stage beneficiation and three-stage sweeping, and the product after sweeping is tailings. The concentrate after the two-stage selection enters the thickener for concentration. After concentration, dehydration is carried out in the dehydration equipment. After dehydration, the underflow is copper concentrate, and the overflow water can be returned to the system for reuse.

The characteristics of this beneficiation process: the beneficiation process is simple and low in cost, and this process can be applied to small and medium-sized copper beneficiation plants.

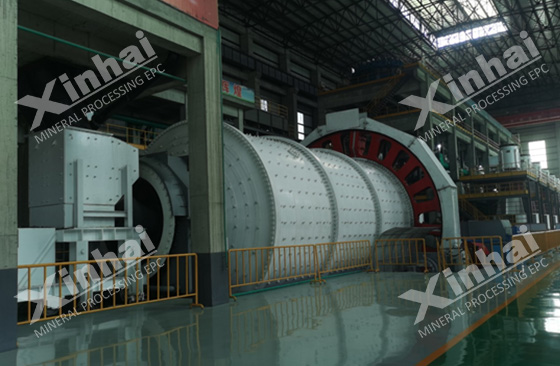

The above content is the mineral processing technology of three kinds of copper ore. Because copper ores with different structures and different compositions use different beneficiation technologies, the beneficiation plant conducts beneficiation test analysis before determining the beneficiation process to determine the ore composition in order to find suitable Mineral beneficiation process design. Xinhai Mining can customize the design of the beneficiation process plan according to the properties of the customer's ore, and customize the improvement of the beneficiation equipment, and can provide a complete set of high-efficiency and high-quality copper beneficiation equipment. If necessary, welcome to consult.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.