In addition to being used to make phosphate fertilizers, phosphorus resources are also important chemical raw materials for the production of yellow phosphorus, phosphoric acid, organic phosphorus and other phosphorus products. They are widely used in food, medicine, fuel, ceramics, dyes and other industries. It is a guarantee Food safety and the material basis of fine phosphorus chemicals play an important role in economic and social development. With the depletion of rich phosphate ore resources, medium and low-grade phosphate ores have become the focus of research. The commonly used phosphate ore separation method is mainly flotation. In addition, there are other beneficiation methods used to process phosphate ores. Phosphorus ore will be introduced ore flotation method and other phosphate ore beneficiation methods.

The flotation process is widely used in the process of sorting phosphate ore. The mineral composition in phosphate ores is relatively complex, and the flotability gap between useful minerals and gangue minerals is small, which is more conducive to the flotation process. Commonly used phosphate rock flotation processes mainly include: forward flotation, reverse flotation, forward-reverse flotation, reverse-forward flotation and reverse-reverse flotation (double reverse flotation) process.

(1) Phosphate ore positive flotation process: Concentrate useful phosphorus-containing minerals directly from the ore into foam products. This method is suitable for silicone gel phosphate ore or easily selected apatite ore. After the phosphate rock is processed by the grinding equipment to the extent of monomer dissociation, appropriate inhibitors and collectors are added at one time to float out the minerals, and the phosphate concentrate can be obtained.

(2) Phosphate ore reverse flotation process: This process needs to be carried out under weakly acidic conditions, which can suppress the phosphate component in the ore and make the useful minerals hydrophobic and hydrophilic to remain in the flotation tank. The gangue minerals enter the foam along with the bubbles under the action of the collector. The reverse flotation process is simple and has high dolomite separation efficiency, so it has been widely used in the mineral processing industry.

(3) Phosphate ore forward-reverse and reverse-forward flotation processes:The flotation of phosphate ore is essentially the separation of colloidal phosphate rock from quartz and dolomite. When the phosphate rock contains both dolomite and quartz, it is necessary to combine forward flotation and reverse flotation. Only by treating ores with flotation technology can we obtain excellent flotation indicators. At this time, forward-reverse flotation and reverse-forward flotation processes appear. Under normal circumstances, these two processes can achieve better flotation results when processing siliceous (calcium-siliceous) colloidal phosphate rock. Depending on the type of ore, the forward-reverse flotation process or the reverse-forward flotation process can be selected.

(4) Phosphate ore reverse-reverse (double reverse) flotation process: The double reverse flotation process of phosphate rock is generally used in calcareous silicate phosphate rocks with high dolomite and quartz content. Usually, the inhibitor H3PO4 is first used to suppress the phosphorus-containing components, so that the carbonate minerals float out, and the main removal of the ore is MgO. An amine collector is used to reverse flotation of feldspar, quartz and other impurities in the concentrate in the tank to achieve the purpose of desilication.

Phosphate ore beneficiation processes are rich and diverse, and different beneficiation processes can be selected according to the type of phosphate ore. In addition to the commonly used flotation processes, there are also scrubbing desliming, gravity beneficiation, roasting-digestion method, chemical beneficiation and gravity-magnetic flotation combination, etc.

Scrubbing and desliming process: It is mainly suitable for rich ores with large mud content and easy to be separated. It is not suitable for processing low- to medium-grade phosphate ores. Scrubbing and desliming is a purely physical beneficiation process with a simple process and no chemical consumption, so the beneficiation cost is low.

Roasting-digestion process: This process requires high silica content in phosphate rock, which cannot exceed 5%. The working principle of this process is mainly to roast the carbonate in the ore at high temperature to release the carbon dioxide, and then add water for digestion. The energy consumption of the roasting and digestion process is high, and there is a problem of lime milk removal.

Chemical leaching process: This process can selectively dissolve dolomite in phosphate rock and is an effective way to remove magnesium oxide. Sulfuric acid is used as the leaching agent during leaching, and the recovery rate of phosphorus pentoxide in the concentrate is low and the production cost is high.

Gravity separation process: It mainly uses the different specific gravity of each mineral in the phosphate rock to separate. It has the advantages of fast separation speed and low pollution.

Dry electric separation process: It is mainly a method of sorting by utilizing the different electrical properties of each mineral in the ore. It is a physical mineral separation method and has the advantages of simple process and no pollution.

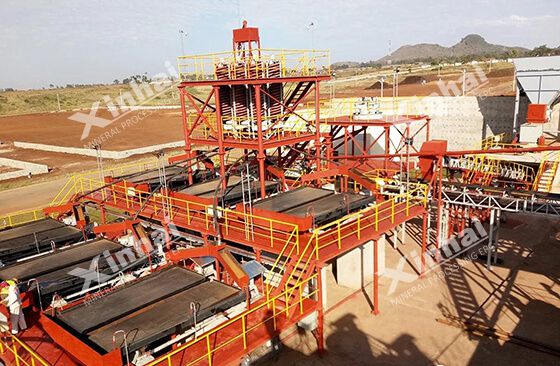

The above is a brief introduction to the phosphate ore flotation method and other mineral processing processes. The selection of a specific mineral processing process needs to be based on the nature and characteristics of the raw ore phosphate rock and the budget of the mineral processing plant itself. The mineral processing test is an important theoretical and data basis for determining the mineral processing process. Xinhai Mining recommends selecting a customized mineral processing plan based on the test results, which can improve the mineral processing effect and economic indicators.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.