As a "new energy metal in the 21st century", lithium is one of the important raw materials in the new energy battery industry. At present, the demand for lithium resources is still very strong, and lithium ore concentration is getting more and more attention. Lithium mineral ation includes many aspects, including flotation test, flotation process and tailings treatment, etc. It is necessary to pay attention to the rationality of each link in the process of mineral ation, so as to utilize lithium resources efficiently. Below, xinhai will take you to understand an efficient floatation separation method of lithium ore to realize the comprehensive utilization of lithium ore and avoid the waste of lithium resources.

The two-section and one-circuit crushing screening process is adopted, the lithium mineral is coarse crushed through the jaw crusher. After the original ore is crushed to the qualified particle size, the product due to the coarse crushing is sent to the 1 # linear vibrating screen by the belt conveyor for screening, and the sieve product is returned to the cone crusher for two-stage crushing, and the sieve product enters the next stage of operation. Among them, the cone crusher and 2 # linear vibrating screen form a local closed circuit crushing screening process, which can better realize the granularity control of coarse selection of lithium minerals, and has the advantages of simple process and large processing amount.

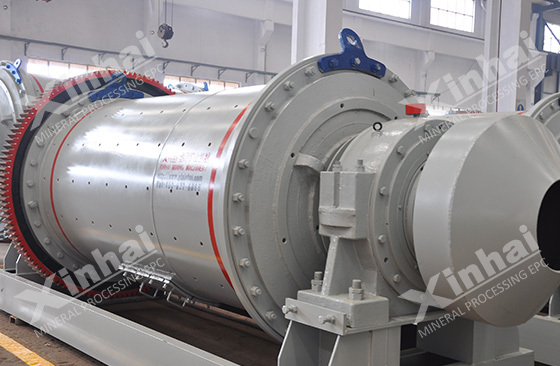

Grinding operation: feed the products of 1 # linear vibrating sieve into the grinding sieve closed circuit process composed of wet energy-saving grid ball mill and 2 # linear vibrating sieve, and then grind the lithium mineral to the qualified size.

Classification operation: after mixing the 2 # linear vibrating sieve product with water, it is pumped to the 1 # graded hydraulic cyclone for grading operation. The overflow part is fed to the 2 # 3 # concentrated cyclone through the slurry pump for sludge removal, and the qualified slurry is used for the next stage of operation.

When separating lithium ore, different separation methods can be selected according to the property of the ore. The specific separation methods include flotation, magnetic separation, and reseparation.

After graded treatment, the pulp is sent into the high efficiency mixing tank, and stirred into the flotation machine. After flotation, the lipidolite concentrate pulp is fed into the hydraulic center through the slag slurry pump to rotate the high efficiency concentrating machine, and the lipolite concentrate is obtained by the belt filter.

After the livite is selected, the remaining pulp in the flotation machine enters the high efficiency mixing tank for mixing, and conducts one coarse, three fine and three sweeps into the flotation machine, and the gangue minerals are left in the flotation tank.

After flotation, the spodumene concentrate slurry is screened through the roller filter, and is sent into the wet magnetic separator and the high gradient magnetic separator for iron removal. After the concentrate slurry is pumped into the hydraulic center by the slurry pump, and the spodumene concentrate is filtered by the disk vacuum filter.

The tailings slurry treated by the high-gradient magnetic separator is subjected to rough separation, sweeping, and concentration on a shaking table to obtain tantalum concentrate, and the gravity-selected tailings are screened by a high-frequency fine screen before being sent to a wet energy-saving overflow ball mill , the qualified slurry is sent to the lithium concentrate

In the process of lithium ore dressing, sludge is done before flotation to create a good working environment for flotation separation. Using the combined process of flotation-magnetic separation-gravity separation, flotation of lithium-micite concentrate and spodumene concentrate respectively, then the iron and magnetic minerals are removed through magnetic separation process, and tantalum concentrate is recovered through the gravity separation process. This lithium ore separation process adopts the correct and reasonable processing process, pays attention to the selection sequence, and can realize the recovery of lithium-micite concentrate, spodumenite concentrate, tantalum concentrate and other ores respectively.

After iron removal, the concentrate slurry is pumped into the hydraulic pressure center transmission thickener by the slurry pump to rotate the efficient concentrator, and then filtered by the disk vacuum filter.

Above is lithium ore efficient flotation separation process, this process is not limited by production scale, not only for the spodumene mineral efficient dressing, and other useful minerals in lithium ore lithium mica, tantalum ore and reasonable recycling, tailings emissions is small at the same time, reached the high value of comprehensive utilization of lithium resources. There is no identical mine in the world, so it is suggested that each concentrator should first develop the appropriate beneficiation process through test and analysis, in order to achieve the most ideal return on investment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.