Kaolin is widely used in ceramics, papermaking, coatings, rubber, and other industries. In recent years, with the rapid development of emerging sectors, the demand for kaolin in electronic ceramics, specialty coatings, and high-grade papermaking has grown significantly. Ensuring high purity and stable quality of kaolin has become a key challenge for suppliers. Xinhai Mining provides comprehensive solutions covering the entire process—from mining to beneficiation—ensuring the quality of kaolin products from the source. This article presents a complete guide to the kaolin mining and beneficiation process.

1. Exploration and Planning

Geological Exploration: Identify the location, scale, grade, and occurrence conditions of the kaolin ore body. Utilize hyperspectral remote sensing technology to shorten the exploration cycle and increase proven reserves.

Design and Planning: Based on exploration results, conduct a feasibility study and develop a mining plan for kaolin. The plan typically includes mining boundaries, mining sequence, transportation routes, and other key parameters.

2. Pre-Mining Preparation

Site Leveling: Involves vegetation removal, topsoil stripping, obstacle clearing, and other operations to form a stable working platform capable of supporting heavy equipment.

Infrastructure Construction: Construct main and temporary access roads in the mining area, establish the primary power supply network, configure backup power systems, and plan water supply and drainage systems.

3. Mining

Select open-pit or underground mining methods based on the ore body’s occurrence conditions and the mine’s production scale.

(1) Open-Pit Mining:

Suitable for kaolin deposits with shallow ore bodies, large scale, and stable rock conditions. The process includes:

Removing topsoil and overburden using excavators, loaders, and other equipment to expose the ore body

Drilling blast holes and using explosives to fragment the ore

Loading and hauling the broken kaolin ore to the processing plant or ore stockyard using dump trucks

(2) Underground Mining:

Applicable to deep-seated kaolin deposits with smaller scale and less stable rock conditions. The process includes:

Driving tunnels around the ore body; tunnel types may include adits, inclined shafts, or vertical shafts depending on the ore body orientation

Developing production tunnels within the ore body

Conducting drilling and blasting using rock drills

Transporting broken ore to the surface via loaders or mine carts

Ventilation and drainage systems must be in place to ensure operational safety underground.

4. Environmental Protection

Implement slope stabilization measures to prevent landslides and collapses. After mining operations conclude, conduct land reclamation and restore vegetation to minimize environmental impact.

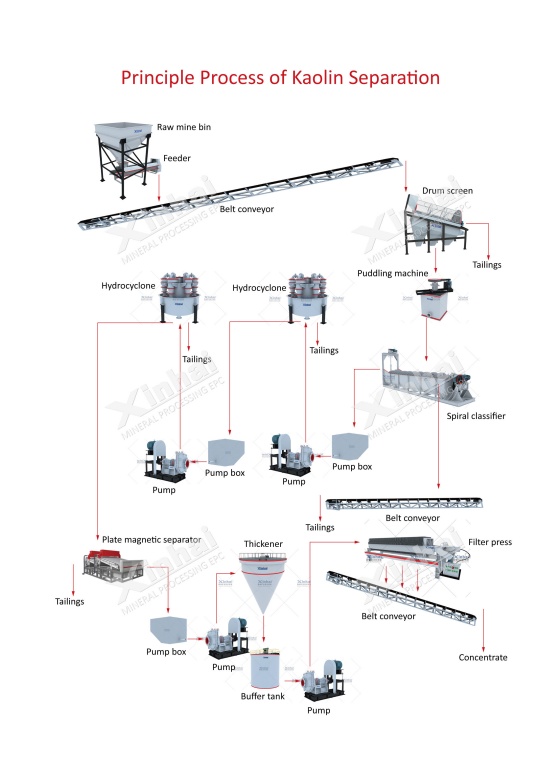

The mined kaolin ore must undergo further processing to improve its purity before it can be applied in downstream industries. The kaolin processing flow includes the following steps:

1. Crushing and Grinding

The kaolin ore is first sent to a jaw crusher for primary crushing, reducing the particle size to ≤100 mm. Next, a cone crusher performs secondary and fine crushing, reducing the size to ≤30 mm. Throughout the crushing stage, vibrating screens are used for particle size classification. Qualified materials proceed to the grinding stage, while oversized particles are returned for further crushing.

The crushed ore then enters the grinding process, which is typically integrated with hydrocyclones or spiral classifiers for classification. Oversized particles are returned for regrinding. The choice of grinding equipment depends on the intended application of the final product:

Ball mills are used for ordinary filler-grade kaolin,

Stirred mills are used for coating and papermaking-grade,

Jet mills (airflow mills) are used for high-purity electronic ceramic-grade kaolin.

2. Purification and Impurity Removal

Flotation: Dodecylamine is added as a collector, and sodium hexametaphosphate as a dispersant and quartz depressant. Mechanical agitation flotation is used to remove TiO₂.

Magnetic Separation: A high-gradient magnetic separator is employed to reduce Fe₂O₃ content from 1.8% to 0.35%.

Gravity Separation and Classification: The slurry is classified using a hydrocyclone. The first stage removes coarse particles (+325 mesh), and the second stage classifies ultrafine particles (−2 μm). A spiral chute is used to enhance kaolin purity.

3. Chemical Bleaching

In the first method, sodium dithionite is added, with pH controlled at 3–4 and temperature maintained at 60 °C. This process can increase the whiteness of kaolin to 92%, but it generates wastewater requiring treatment.

In the second method, ozone oxidation is applied to the concentrate slurry, with an ozone concentration of 50 ppm at room temperature. This method can increase whiteness to 90%, and it is environmentally friendly with no harmful residues.

4. Drying and Packaging

After beneficiation and bleaching, the kaolin is dried and packaged for sale. The drying method is selected based on the end use:

For coating and ceramic-grade kaolin, spray drying is used (moisture ≤1%).

For rubber and plastic-grade, flash drying is preferred (moisture ≤0.5%).

For pharmaceutical and food-grade, belt drying is employed (moisture ≤0.3%).

Kaolin processing involves a complex flow with more than 20 procedures. Due to factors such as ore composition fluctuations, process parameter drift, and equipment wear, the whiteness, viscosity, and particle size of the final product can vary from batch to batch. Therefore, stabilizing product quality is of critical importance.

Xinhai Mining has achieved a breakthrough in product stability through a "three-in-one" quality control system:

Source Control:

The raw ore composition fundamentally determines product quality. During beneficiation testing, an X-ray fluorescence (XRF) online analyzer is used to monitor the ore composition in real time. The processing parameters are then adjusted based on the specific mineral composition to ensure consistency.

Process Control:

PLC (Programmable Logic Controller) automatic control systems are deployed at critical stages such as grinding and flotation to maintain particle size deviation within ±0.3 μm.

Final Quality Assurance:

Each batch of products undergoes six comprehensive inspections, enabling precise tracking and monitoring of product quality.

Conclusion

This article has introduced the kaolin mining process, beneficiation techniques, and quality control strategies. Xinhai Mining offers complete EPC+M+O services for kaolin-related mining and mineral processing projects. For further inquiries or cooperation, please feel free to contact us.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.