Kaolinite mineral, also known as dolomite, is a type of clay found in nature. It is an essential ingredient in the manufacture of white pigment and china. The whiteness is the main factor affecting the value of kaolinite. The detrimental impurities contained in the kaolinite such as iron, organic substances, and dark minerals will affect the whiteness, so we must remove the impurities to improve the value of the kaolinite product.

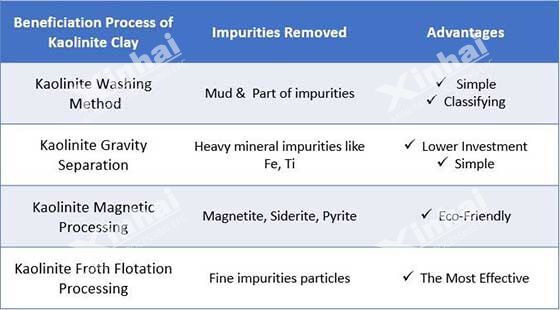

The common kaolinite mineral beneficiation processes are as follows:

The washing method is adopted to remove the mud on the surface of kaolin and part of impurities before separation. For example, the cyclone unit can not only remove part of the impurities and mud but also classify the mineral into different particle sizes. That will be more convenient for the subsequent processing stage.

The gravity separation is an effective method to separate heavy minerals and light gang minerals based on the difference in density. For example, you can use the centrifugal concentrator to remove high-density impurities like iron, titanium, and manganese. However, you can’t remove other fine impurities or obtain qualified kaolinite products only by the gravity processing method.

Almost kaolinite ore contains 0.5%-3% of iron impurities like magnetite, ilmenite, siderite, pyrite, and other colored impurities.

The magnetic separation method can be adopted to remove strongly magnetic minerals. For weakly magnetic minerals, there are two main methods:

1) Roasting-Magnetic Separation

Turning the weakly magnetic minerals into ferromagnetic iron oxide by roasting so we can use magnetic separation methods to remove the iron impurities.

2) High-Gradient Strong Magnetic Field Magnetic Separation

Adopting the high-gradient strong magnetic field magnetic separation method to remove the iron metal.

Magnetic separation is an eco-friendly method that is widely used for the non-metal beneficiation process.

However, it is difficult to obtain high-grade kaolinite products only by a single magnetic separation method, you need to do chemical treatment to further reduce the iron content in kaolinite products.

Kaolinite froth flotation is a highly effective method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a kaolinite mineral slurry. The particles with attached air bubbles are carried to the surface and removed, while the particles that remain completely wetted stay in the liquid phase.

The common methods of kaolinite flotation processes are ultrafine particle flotation, two-layer flotation, and selective flocculation flotation.

Because we need to add chemicals during the process, which increases the production cost and easily causes environmental pollution.

It is difficult to obtain high-grade kaolin products through a single process, and a combination of multiple processes can be used to improve the quality of kaolin products.

Get professional advice here for the most suitable combined kaolinite mineral beneficiation process.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.