Hematite, as one of the most important iron mine resources, can be used to make pigments, gemstones, ballast ships, and even radiation shielding for medical treatment and scientific research equipment. Therefore, the application of hematite is wide in human life. However, the hematite was regarded as tailings to discard In the past iron ore mining process. In this way, the hematite can not be fully utilized. Thus, it is important to know about the hematite beneficiation process.

How to recycle much more hematite efficiently from raw ore? The hematite iron ore beneficiation process includes crushing and screening, grinding and classification, magnetic selection, reverse flotation, concentration, and filtration. You can get the detailed hematite selection process from the following.

This process includes raw ore crushing and screening. The followings are the detailed description of the hematite crushing and screening treatment.

Raw ore crushing process: the raw mine from the mineral source will be stored in the original ore warehouse. Then, it is sent into an ore crusher for pulverizing through the chute feeder machine. The next hematite dressing process can be performed when ore particles are broken to the feeding size suitable for mining mill machines.

Ore screening process: after crushing, most hematites can be transported into the ore mill for grinding. However,there are some ore stones which is too big to send into the ore grinding mill machine. At this time, you should use the screening machine to remove these large mine stones which can damage the ball mill equipment. To improve the utilization of raw ore materials, these stones can be sent back crushing process for re-crushing. By doing so, you can lower the risk of ore mill machine damage. At the same time, you can get more hematite materials from the raw ore.

The above is about the crushing and screening in the hematite beneficiation process. The hematite powder will be transported into a powder ore warehouse to store through a belt conveyor. As mentioned above, you need machines for feeding, crushing, conveying, and screening. You can select and purchase the right machines according to your hematite dressing plant scale and production capacity.

To separate the hematite concentrate from the gangue mineral as much as possible, the processes of grinding and classifying are needed. The details of hematite grinding and classifying process are as follows.

Primary grinding and classifying:

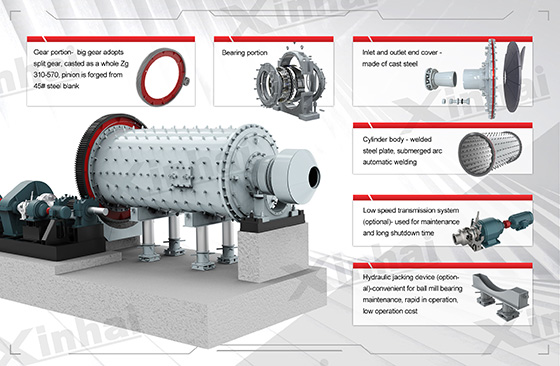

With the help of an electronic feeding machine and belt conveyor, those crushed hematite ores will be into the ball mill machine for grinding. The forces of gravity, friction and impact in the ball mill cylinder will make the ore materials smaller and smaller. After the hematite ore powder reaches the required particle size, it can be discharged to complete primary grinding. After that, the hematite powder needs to go through the check classification. The powder will be pumped into a hydro cyclone by the slurry pump. After primary classification, quality hematite can be sent into the magnetic separator for selection. The left need to go back grinding process for re-grinding.

Second grinding and classifying:

To get finer hematite powder, you need to perform a control classification process. The overflowed hematite from a hydro cyclone will be sent to the next ore dressing process. The left of classification will go through second-grinding to meet the ore dressing standard.

From the above, you can know the process of hematite grinding and classifying. At this stage, the machines you need to buy are ball or rad mill, hydro cyclone, and slurry pulp. These mineral processing machines from Xinhai are on sale at the best cost. You can get a suitable hematite grinding and classifier in Xinhai. Welcome to consult.

After the grinding and classifying process, the next step you need to do is that separate the hematite from the useless mineral. In this way, you can get better hematite concentrate powder. As for the method of hematite selection, we recommend you adopt the composite mineral processing mode which includes magnetic separation and reverse-flotation separation. The specific operation steps are as follows:

The first step: magnetic selection

Classified hematite powder will be sent into the magnetic separator for roughing selection. As mentioned in stage2, the rough hematite concentrate obtained from the magnetic separator will be pumped into the second hydro cyclone for control classification. The magnetic tailings will flow back to the tailings pond for other processes.

The second step: reverse-flotation selection

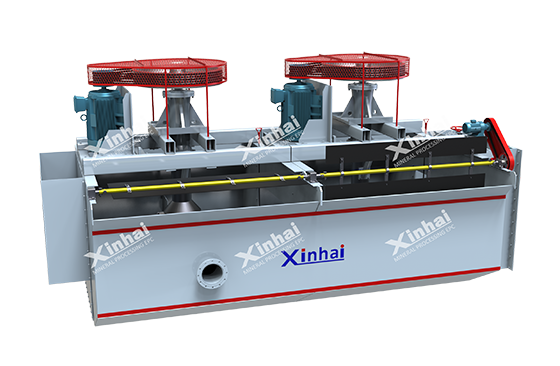

To get high-grade hematite products, the concentration process is dispensable. Based on the hydrophobicity of hematite, we recommend applying the reverse-flotation selection method. To improve selection efficiency, you can add flotation reagent into ore pulp. Then, you can use the agitation tank to make the ore pulp mix evenly with agents. The next process is that the mixed ore pulp will flow into the flotation cell for a three-time flotation process. After the flotation process, the tailings will flow into the tailings warehouse to store.

This is the hematite magnetic and reverse-flotation selection process. At this stage, you should deploy a magnetic separator, flotation cell, and agitation tank. There are many types of magnetic separators, flotation cells, and agitation tanks you can choose from in Xinhai. Welcome to call us for a detailed consultation.

The concentrate ore pulp from the reverse flotation selection process contains a lot of water. To get finished products of hematite concentrates, you need to perform a thickening and dewatering process. The followings are the detailed process of thickening and filtering.

Thickening: after flotation selection, the slurry pump machine will pump the mineral pulp into the thickener. The hematite particle in the ore pulp will be falling because of its gravity. After a while, there is a layer of ore sediment at the bottom of thickener pool. Meanwhile, the rake at the bottom of thickener will make the sediments move to the bottom center. The hematite sediment will flow out of the thickener to process the following dewatering and filtering. To thicken the ore pulp efficiently, the quality and performance of mineral thickeners are very important. The mineral thickeners produced by Xinhai can be available in large, medium, and small-scale hematite processing plants. In Xinhai, you can choose the thickener machine with a diameter from 2.5m to 50m. Welcome to contact us for consultation.

.jpg)

Filtering: The concentrate flowing from the thickener machine needs to go through the next dehydration operation. We recommend you use the disc vacuum filter to improve the dewatering efficiency and lower the energy consumption. When the hematite concentrate slurry flows into the filter machine, the ore particles will be adsorbed on the filter cloth of disc under the action of negative pressure formed by the vacuum pump. After a while, the filter cakes with some thickness will be formed on the filter cloth. Pressure on the blower and scraper on the filter will make this kind of filter cake fall into the chute. The remaining filtrate will be discharged from the center axis. After that, you can get the hematite concentrate products.

The mentioned above is the specific description of thickening and filtering in the hematite beneficiation process. From the above, you can know that the machines you will use are a thickener machine and a filter machine. These machines are being produced in Xinhai. Therefore, you can find them in Xinhai easily. What’s more, we can recommend the most suitable ore dressing machines to you based on the yield and budget of your mineral processing plant.

You can know well about the detailed hematite beneficiation process and needed equipment from the above. For the ore dressing process, the process flow design and equipment selection are very important. Both of them will impact the grade of final hematite concentrate and the recovery rate of minerals directly. Therefore, it is vital to select the correct hematite dressing process and equipment. Xinhai, a company with more than 20-year experience in ore dressing plant design and mineral processing machines production, has participated in many hematite beneficiation projects at home and abroad. Therefore, we have the confidence to design and provide a whole set of hematite beneficiation production lines and machines. If you need, email or call us, please.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.