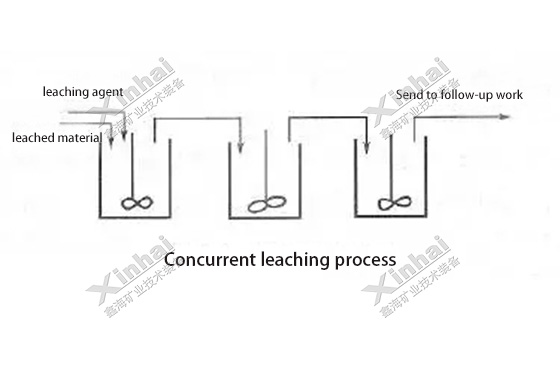

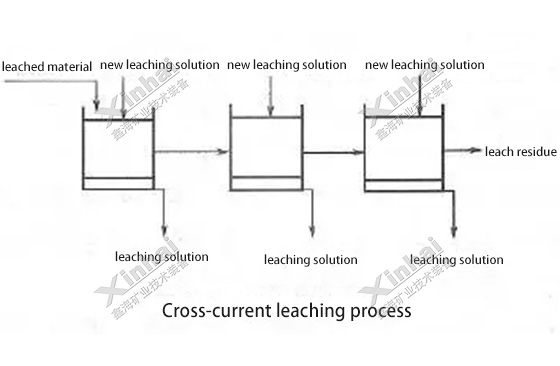

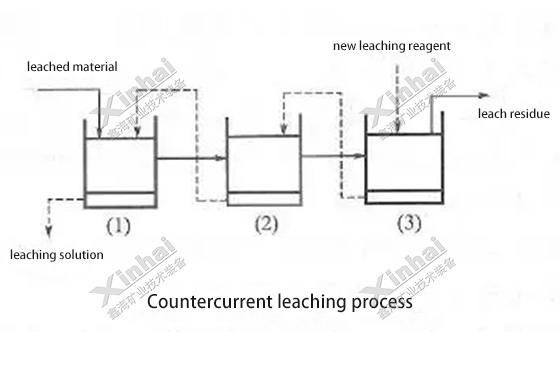

In the material leaching process, there are three main leaching processes according to the leaching material and the movement direction of the leaching reagent: concurrent leaching process, cross-current leaching process, and countercurrent leaching process.

The leached material flows in the same direction as the leaching reagent. The concurrent leaching process can get the leaching solution with a higher content of target components. The reagent consumption is lower, but the leaching speed is slow, so the higher leaching rate can be reached after a long leaching time.

The leached material is leached by the several new leaching reagents. The leachate obtained from each leaching process is uniformly sent to the follow-up operations. The cross-current leaching process has a fast leaching speed. The leaching time is shorter and the leaching string is higher. But the volume of the leaching solution is large. The concentration of the residual reagent in the leaching solution was higher, so the reagent consumption is high, and the content of the target components in the leaching solution was low.

The leached material and the leaching reagent move in the opposite directions, that is, the depleted material after the several leaches comes into contact with the new leaching solution, while the original leached material contact with the leaching solution. The countercurrent leaching process can obtain the leaching solution with a higher content of the target component and make full use of the residual reagent in the leaching solution. Therefore, the consumption of the leaching agent is lower, and the leaching velocity is lower than the cross-current leaching process, so more leaching stages are needed to obtain a higher leaching rate.

The infiltration tank leaching process can adopt the concurrent leaching process, cross-current leaching process or countercurrent leaching processes. The heap leaching and in-situ leaching generally adopt a concurrent cyclic leaching process, while the continuous agitation leaching generally adopts a concurrent leaching process. If the cross-current or countercurrent leaching processes are used, the solid-liquid separation operations shall be added between the multiple levels. The agitation leaching of the intermittent operations generally adopt concurrent leaching, cross-current or countercurrent leaching processes, but the solid-liquid separation is required after each leaching. The clear leaching solution can be obtained directly from the infiltration tank leaching process, but the slurry obtained by the agitation leaching can only get the clarified leaching solution or the dilute slurry containing a small number of ore particles after the solid-liquid separation.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.