The rock gold in the mountain is separated from the quartz vein caused by water erosion. Most of this kind of gold is fine as the sand, so it is called alluvial gold. but what are the alluvial gold mining processes? And what is alluvial gold equipment commonly used in the alluvial gold washing plant?

Due to the free state of gold in sand gold deposits, and the specific gravity difference between gold and sand is very obvious, the gravity separation method is an ideal and efficient method to extract gold from the sand.

The principle of the alluvial gold mining process is to recover gold and all kinds of associated heavy minerals from raw ore as much as possible by the gravity dressing method. The lower limit of the particle size of gold recovery by gravity separation method is generally 0.01mm. In the practice, the alluvial gold mining process generally includes breaking, screening and gravity separation.

Many gold ore deposits contain cementing mud masses, some of which have a particle size greater than 100mm, sometimes even cement on gravel or pebbles. If not broken in time in the alluvial gold washing plant, the mud will be discharged along with the waste rock during the screening process, resulting in the loss of gold.

The screening operation can remove 20-40% of the waste rock (gravel, pebble), which is an indispensable operation in the alluvial gold washing plant. So, screens are essential alluvial mining equipment. The determination of screening parameters must be based on the size composition of gold in the original ore. According to the ore washability, the alluvial gold washing plant generally can use plane vibrating screen, cylinder screen, scrubbers with the screen, hydraulic washing equipment.

Due to the different size composition of the gold in the alluvial gold deposit, the effective particle size limits of the materials treated by various gravity separators are also different. In general, the alluvial gold equipment mostly adopts jig as the roughing equipment and the shake table as the concentrating equipment for the jig coarse concentrate. Some low-grade alluvial gold washing plant adopts the chute as roughing equipment, the jig as scavenging equipment and the shaker table as the concentrating equipment. Therefore, the reasonable alluvial gold mining process is mostly the joint operation of several kinds of gravity separators.

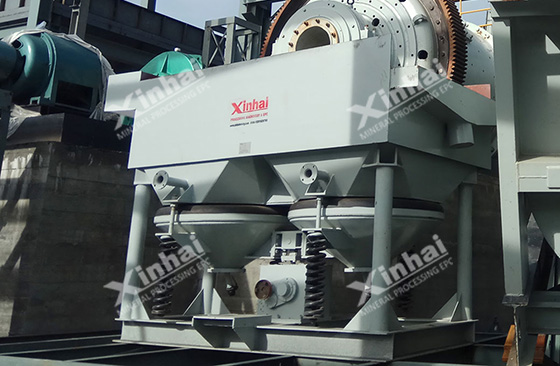

1. Alluvial gold equipment: Jig

The jigging process is to mix the mineral particles with different specific gravity and stratify them according to the specific gravity in the variable speed medium flow with vertical movement. The minerals with small specific gravity are in the upper layer, while the minerals with large specific gravity are in the lower layer. The layered materials are discharged separately by means of machinery and water flow.

The jig used for gold recovery is suitable for separation of coarse mineral particles (any raw mineral materials except for superfine material mineral), the range of beneficiation size is from 50 mm to 0.074 mm. The lower limit of beneficiation size is 0.04 mm for the alluvial gold mining process if the proportion difference is equal to or larger than 1.25, and the ore achieves the monomer dissociation.

2. Alluvial gold equipment: Shake table

The shake table is a kind of gravity separator in the inclined medium flow. It uses the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove) to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

The shaking table used for the alluvial gold mining process is suitable for processing the minerals with fine particles. According to the different particle sizes, the ore can be divided into a coarse sand bed, fine sand bed and slurry bed. The coarse sand bed is suitable for the material particle size between 2.0 mm to 0.5 mm, the fine sand bed is suitable for processing material particle size between 0.5 mm to 0.074 mm, the slurry bed is suitable for processing the material particle size between 0.074 mm to 0.037 mm.

3. Alluvial gold equipment: Chute

The chute used in the alluvial gold washing plant is a kind of gravity separator relying on the inclined water flow. The material particles settle on the different zone of chute under the joint force of water flow, mineral gravity, frictions between mineral grain and chute bottom. The particles with a small proportion are taken away by the water flow, and the particles with a large proportion are left.

The chute is suitable for the treatment of the alluvial gold with low mud content. The particle size range is 0.6 mm-0.03mm. Gravity separation by chute used in the alluvial gold mining process is featured with simple structure, large processing capacity and low comprehensive cost.

In the production, the selection of alluvial gold mining process and alluvial gold equipment need to be determined according to the specific ore properties and characteristics. Not all the alluvial gold washing plants adopt the same alluvial gold mining process and alluvial gold equipment can obtain the ideal separation effect. It is suggested that the mineral processing test shall be carried out first, so as to develop reasonable alluvial gold mining process and tailor-made alluvial gold equipment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.