Gravity separation method is one of the common methods in gold recovery, which is to separate the materials by different specific gravity and different settling velocity in the medium. For the arenaceous gold deposit, the gold mostly exists in the form of monomer natural gold, which has large density difference with gangues. Therefore, adopting the gold gravity separation method can obtain good gold recovery effect and economic benefit.

There are many kinds of gravity separation methods used for gold recovery, including gravity separation by jigging, gravity separation by shaking table, gravity separation by spiral chute, gravity separation by spiral, gravity separation by centrifugal separator and gravity separation by wind power. Among them, the common gravity separation methods used for gold recovery are gravity separation by jigging, gravity separation by shaking table and gravity separation by spiral chute.

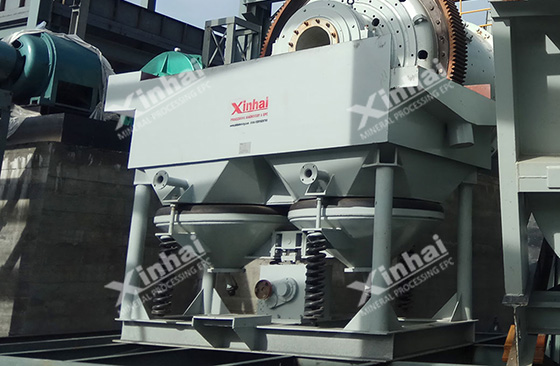

The main equipment used in the gravity separation by jigging is the jig. The jigging process is to mix the mineral particles with different specific gravity and stratify them according to the specific gravity in the variable speed medium flow with vertical movement. The minerals with small specific gravity are in the upper layer, while the minerals with large specific gravity are in the lower layer. The layered materials are discharged separately by means of machinery and water flow.

Gravity separation by jigging used for gold recovery is suitable for separation of coarse mineral particles (any raw mineral materials except for superfine material mineral), the range of beneficiation size is from 50 mm to 0.074 mm. For the placer gold ore, the lower limit of beneficiation size is 0.04 mm if the proportion difference is equal to or larger than 1.25, and the ore achieves the monomer dissociation. Gravity separation by jigging used for gold recovery is featured with simple process operation, large equipment processing capacity, which is widely applied in the roughing gold recovery.

The main equipment used in the gravity separation by shaking table is the shaking table, which is separation equipment in the horizontal medium flow. The transmission mechanism drives the bed surface to do the longitudinal reciprocating movement, the slipstream and the differential motion. The ore grain in reciprocating motion is subjected to delamination that is perpendicular to the bed surface and dissociation that is parallel to the bed surface, which can make the material with different granularity discharge from the different zone of bed surface, realizing the separation.

Gravity separation by shaking table used for gold recovery is suitable for processing the minerals with fine particles. According to the different particle sizes, the ore can be divided into a coarse sand bed, fine sand bed and slurry bed. The coarse sand bed is suitable for the material particle size between 2.0 mm to 0.5 mm, the fine sand bed is suitable for processing material particle size between 0.5 mm to 0.074 mm, the slurry bed is suitable for processing the material particle size between 0.074 mm to 0.037 mm.

The feed size of gravity separation by shaking table is generally between 3mm-0.019mm. This gravity separation method is featured with stable and reliable gold recovery, clearly visible ore belt distribution, higher rich ore ratio than other methods, easy to manage and the required ore can be separated at once.

The main equipment used in the gravity separation by spiral chute is the spiral chute, which is a separation equipment with the help of ramp flow. The material particles settle on the different zone of chute under the joint force of water flow, mineral gravity, frictions between mineral grain and chute bottom. The particles with small proportion are taken away by the water flow, and the particles with a large proportion are left.

The spiral chute is suitable for the treatment of micro-grained materials with low mud content. The particle size range is 0.6 mm-0.03mm. Gravity separation by spiral chute used for gold recovery is featured with simple structure, large processing capacity and low comprehensive cost.

The above are three gold gravity separation methods only used for monomer dissociated gold deposits (placer gold deposits). The gravity separation method is rarely used in the vein gold deposit, which often combines with other processes, such as gravity separation-floatation joint gold recovery process. In the grinding and classification circuits, using the jig, spiral chute and shaking table to recycle the easy-to-dissociated coarse particles, and create better conditions for the subsequent flotation and cyanide process, which can effectively increase the total gold recovery rate.

In the gold recovery process, the selection of gravity separation should be determined according to the nature of the gold ore. It is suggested that the mineral processing test should be carried out before selecting the process.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.