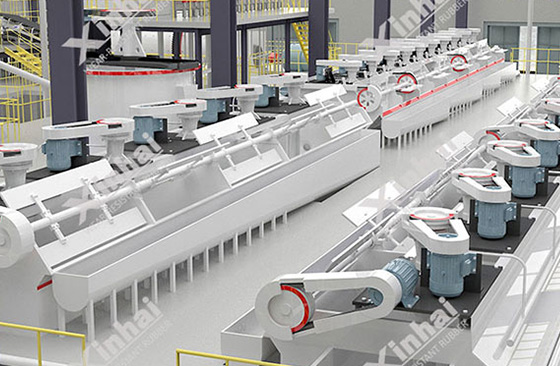

As the common mineral processing process, the froth flotation process is widely used in the concentrator. Because the froth flotation process is strict with grinding fineness, pulp density, flotation reagent, the flotation plant operators must inspect the flotation conditions during the operation of the flotation machine. Here are some common problems of froth flotation process and their and solutions.

This situation is owing to the substandard grinding fineness of material in the flotation machine or the dosage problem of flotation reagent. If the grinding fineness is not up to the target, the grinding fineness should be appropriately increased, which can increase the number of grinding stages or stage grinding.

If the problem of flotation reagent dosage arises, the flotation reagent should be tested and the dosage and index of flotation reagent should be redetermined. For example, a copper and cobalt oxide mine in Congo, the main copper content is malachite, and the cobalt mineral is hydrocobalt. In order to improve the froth flotation process effect, the sodium thiohydride and ammonia sulfide was used to improve the effect of the froth flotation process in a 1:1 ratio.

When the flotation tank appears larger foam, and the foam has the reflective surface, the possible reason is that the flotation reagent is added too much. At this time, the flotation plant operator should adjust the flotation reagent dosage appropriately, and observe whether the flotation foam condition is improved.

The fault may be caused by the blockage of the suction tube. At this time, the flotation operator should stop the suction tube and clean it

There are four possible reasons for this situation, one is the overflow concentration is too dilute, two is the position of the liquid level adjustment plate is too high, three is the slurry overflow concentration is too thick, which may also lead to coarse size and serious sand sinking, four is the dosage of inhibitor and regulator is too large, resulting in the failure to produce the appropriate amount of foam. When this happens, the flotation operator should first observe the situation, control the pulp concentration and fineness, and pay attention to control the dosage of regulator and inhibitor to get the better index of the froth flotation process.

The possible reasons for the falling of slurry level include the grinding fineness is too thick, the processing capacity is increased, or the reagent dosage is insufficient. The flotation operator can adjust the grinding and classifying, reduce the amount of ore feeding, or adjust the reagent dosage.

Generally, this problem of froth flotation process has the following reasons: the ore feeding is too much, the inflating volume is too much, the middle box and the liquid level adjustment plate is blocked, the suction capacity of the suction tank is insufficient, the pressure of flushing water is too small. In these cases, the blockage of the liquid level adjustment plate is the most likely to cause a sand setting, the flotation operator can minimize the level adjustment plate, dredge clogs, open the bottom valve if necessary, to make the slurry flow and check whether the pipe is blocked. At the same time, the flotation operator should know the amount of ore feeding and overflow concentration, timely find out the reason, and adjust to ore feeding according to reasons.

When this phenomenon occurs, the flotation operator should first stop the ore feeding, then open the bottom flow valve at the bottom of the tank, and then start the ore feeding and block the bottom flow valve when the slurry flow returns normally. At the same time, pay attention to control the slurry concentration.

The above are seven common problems and their solutions in the froth flotation process. For the small and medium mineral processing plant, it is suggested to choose the turn-key mineral processing solution provider from the mineral processing test to the mine operation, so that the above problems can be solved effectively, the flotation operator can also be effectively guided, which reduces problems in the subsequent froth flotation process.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.