With the more complex and multifaceted international situation and the rise of the new energy industry, the mining market is facing new opportunities and challenges, and the development of non-metallic minerals has also ushered in a new development momentum. Here, I will take you to inventory some of the non-metallic mineral processing plant projects completed by Xinhai!

According to the nature of the project's raw ore, the project adopts a flotation process to process graphite raw ore with a processing capacity of 3,000 tons per day, and Xinhai customizes the main and auxiliary equipment for the production line to effectively meet its process use requirements.

Compared with several companies, Xinhai was chosen for this project to provide the one-stop mineral processing EPC+M+O service, including research and design, the whole set of equipment, installation and commission, etc. In order to make the project more advanced and reliable, the Japanese side specially invited Xinhai to visit six silica sand (quartz sand) finishing plants in Japan during the project proposal development stage.

Through the inspection and visit, Xinhai learned about the advanced technology, equipment, and idea of advanced silica sand (quartz sand) finishing machining. Combining with the exquisite technology, equipment, and idea of Xinhai, Xinhai designed a truthful silica sand (quartz sand) production line.

Xinhai overtook Anhui 1000tpd quartz sand processing EPC+M+O project. The service included mineral processing experiment, mine design, the whole set of equipment, installation and commission, etc. In the prophase stage, Xinhai mine research institute carried out a mineral processing experiment with 50 tons of ore samples. Later, Xinhai mine design institute conducted a field visit and designed the actual processing flow according to the result of the mineral processing experiment.

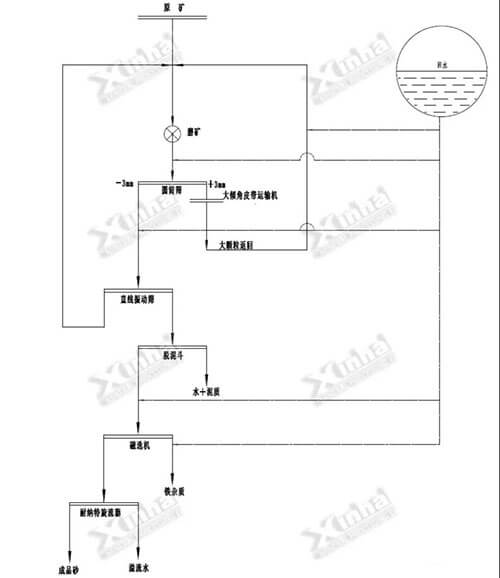

Two-stage and a half-closed crushing and screening – one stage closed grinding – desliming – magnetic separation – concentrate dewatering

This client of this project entrusted Xinhai research the quartz processing project. After field sampling for a comprehensive condition test, Xinhai developed a reasonable process plan for customers.

The technical and economic indicators of the raw ore magnetic separation – scrubbing process ’ and ‘ raw ore magnetic separation – flotation – scrubbing process ’ were compared through experiments, and the ‘ raw ore magnetic separation – scrubbing process ’ was selected for this project. The process can obtain quartz concentrate with a yield of 84.03 %, SiO2 grade of 99.64 %, Al2O3 grade of 0.093 %, Fe2O3 grade of 0.038 %. Customers are satisfied with this result.

Xinhai provided a one-stop processing service for the Vietnam 800tpd processing project, including mineral processing experiment, mine design, whole set equipment, installation, and commission.

In the previous period, after Xinhai Mining and Decoration conducted tests on the incoming samples, it was found that the graphite concentrate with a yield of 14.20%, a fixed carbon content of 92.30%, and a recovery rate of 87.91% could be obtained after nine stages of grinding, one roughing, one sweeping and nine selections of the raw ore. In order to get part of the high carbon graphite concentrate, the graphite concentrate was wet screened, and the +140 mesh concentrate yield was 3.68% with 95% fixed carbon content; -140 mesh concentrate yield was 10.72% with 91.46% fixed carbon content, and then it was determined that the processing plant adopts a two-stage closed circuit crushing - nine-stage closed circuit grinding and classification - one coarse, two scavengings, ten concentrating flotation process.

This project was the China-Uganda Energy Industrial Park cooperation project. Xinhai finished the commission of this project all at once in limited time, which witnessed the unprecedented “Xinhai Speed”.

The raw material of the processing plant is the high phosphorus tailings of the magnetic separation plant (-200 mesh accounts for 50%), and the raw material of the project is conveyed to the high concentration mixing tank for slurry mixing. The agitated slurry is transported to the raw ore desliming cyclone for desliming, and the ball mill forms a closed circuit grinding system with pumps and classifying cyclone. The designed flotation process is a coarse, sweeping and two fine positive flotation process, the flotation concentrate is transported to the concentrate dewatering system for dewatering, and the dewatered product is phosphate concentrate; the flotation tailings are transported to the tailings dewatering system for dewatering, and the dry tailings are transported to the tailing storage by dump truck; the dewatered filtrate is returned to production for recycling.

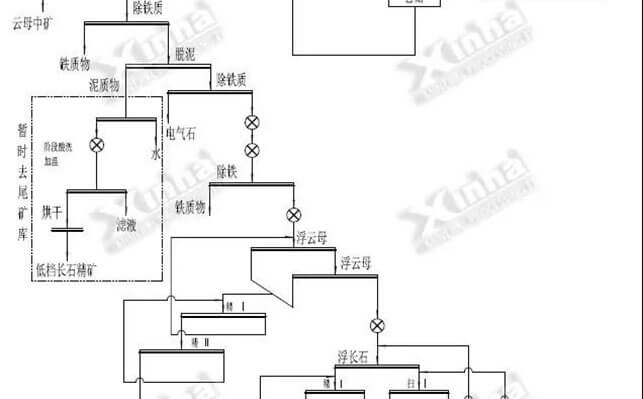

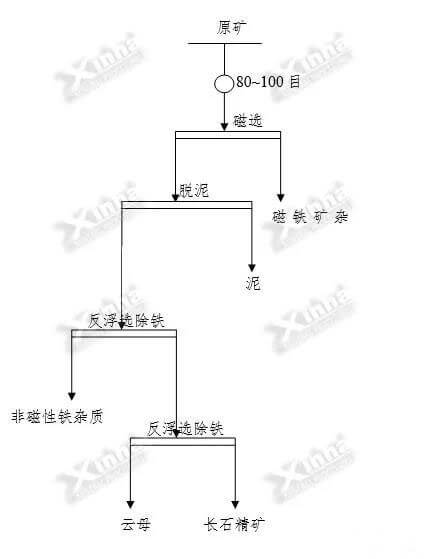

Xinhai has undertaken the project of a 700tpd feldspar ore processing plant in Hunan. According to the composition of the original ore material, Xinhai learned that the main minerals of the project ore are feldspar and quartz, with a small amount of white mica and tourmaline minerals. Among them, solving the separation problem of quartz and feldspar was the key to getting qualified feldspar concentrate and quartz concentrate.

After a detailed beneficiation test, Xinhai decided to adopt two and a half-closed circuit crushing and screening - one closed-circuit grinding - gradation and de-hybridization - magnetic separation - flotation - concentrate dewatering process for the project. The feldspar concentrate (K₂O+Na₂O) of the project is 14.16% with 54% yield; quartz concentrate grade (SiO2) ≥97.87% with 10% yield; the volume of K₂O+Na₂O concentrate reaches 81,000 tons/year and the volume of SiO2 concentrate reaches 15,000 tons/year.

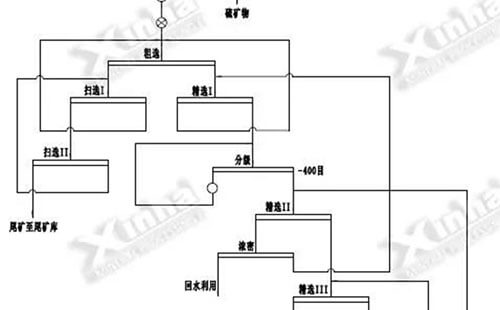

The project adopted a two-stage closed circuit crushing and screening - a full closed circuit grinding (one stage grinding + two stage classification) - desulfurization flotation - fluorite flotation (a coarse two sweep eight fine + fine I concentrate re-grinding closed circuit) - concentrate dewatering process, to obtain qualified fluorite concentrate products, while achieving the rational use of resources.

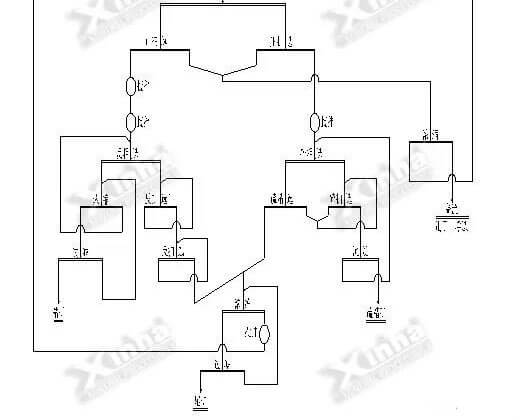

After analysis, it was found that the ore types of the project include carbonaceous phosphorites, dolomitic phosphorites, carbonaceous pyrite phosphorites, silica-bearing, and carbonaceous phosphorites. The main minerals include colophosphorite, fluorapatite, dolomite, charnockite, quartz, calcite, pyrite, a small amount of barite, sodium feldspar, and chalcopyrite, galena, sphalerite, etc., of which the phosphorus content was 17.84%.

According to the nature of the original ore, the project adopted the decarburization - forward and reverse flotation process, with one coarse, one fine, and one scavenging process for positive flotation, one coarse and two sweep processes for reverse flotation, and one coarse, one fine and one sweep process for sulfur separation, resulting in a phosphate concentrate with a grade of 30.04%, a concentrated rate of 48.28% and a recovery rate of 78.18%.

A processing plant in Zhangjiakou, Hebei commissioned Xinhai to design and study a 500t/d ultra-pure quartz sand project, requiring the SiO2 content in the product to reach ≥99.95%. Such a high SiO2 content requirement meant that not only must almost all impurities in the quartz sand be selected out but also no new impurities such as iron, dust, and plastic must be mixed in the production process.

With skillful silica sand (quartz sand) technology and equipment, mineral processing and purification chemicals, etc., Xinhai has developed a reliable technical program and got the favor of the customer. The customer entrusted all the late complete sets of equipment, installation and commissioning, worker training, and other links to Xinhai.

The client of this project entrusted Xinhai to provide "mineral processing EPC+M+O service" for its 400tpd feldspar ore processing plant. The main minerals of the project were potassium feldspar and sodium feldspar, with 60~80% content.

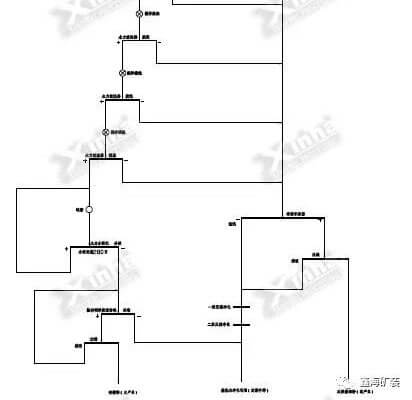

Through the selectivity test of the ore sample of the project, Xinhai decided to adopt the two-stage closed circuit crushing - one stage closed circuit grinding - magnetic separation - desliming - reverse flotation separation and dewatering process of the concentrate. Finally, the concentrate rate reached 73.31%. The whole processing plant is built according to the terrain, the buildings are relatively concentrated, and the equipment configuration in each plant of the processing plant takes into account the main slurry to achieve self-flow as far as possible, and the similar equipment operation is relatively concentrated configuration, which is convenient for operation and management.

After learning about the 2000t/d silica sand (quartz sand) project in Japan undertaken by Xinhai, the customer of this project approached us and put forward higher technical requirements, requiring that the accumulated content of heavy minerals in the produced silica sand (quartz sand) products should not exceed the standard of 5 parts per million.

After repeated trials and design scheme argumentation with the customer, Xinhai Mining Equipment provided a set of one-stop overall services of silica sand (quartz sand) design and research, complete sets of equipment, installation and commissioning, etc. for the customer to effectively meet the technical needs of the customer.

The development momentum of the non-metallic mining industry is strong, and it still needs to move forward to high quality. Xinhai will always practice the service concept of "what you need is what we can do", continuously promote the technological innovation and application of mineral processing technology and equipment, deeply develop the service road of plant processing, and continue to provide one-stop and customized plant processing solutions for global customers!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.