In recent years, with the deep development of industrial information technology, auto-controlling, the auto-adjusting device with supplementary systems and software develops fast. For the mining industry, the application of automation technology largely improves production safety, reducing operation costs, downsizing staff, and improving efficiency. It is significant for the improvement of production efficiency. Depending on the processing construction experience over 20 years, Xinhai puts forward the mine automated system compatible with beneficiation plant, pushing mine high-efficiency development.

Automation uses intelligent instruments, automatic and intelligent equipment, building information, and data collection system to collect data and realizing real-time automation controlling. It is an important technical means to reduce operating costs and improve product safety. The mine automated system changes internal operating factors of the mine, realizing continuous optimization and improving mine production value.

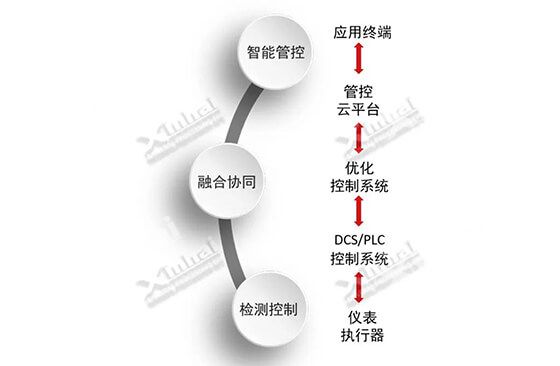

In recent years, mine automation gradually develops from decentralized cell automation technology to an optimized whole. Supported by rapidly developing information technology, the mine automated system rapidly covers the mine field equipment, controlling, management, and other layers, becoming the right path of the mine intelligent development.

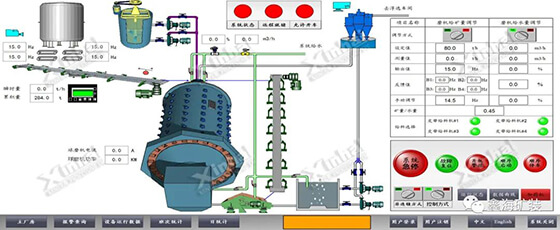

According to the design plan, instrument actuators are arranged on the key point, including online granulometry for pulp, online pulp taster, image analyzer for fragmentation of ore or flotation foam, etc. frequency converter, automatic valve, and other devices. All the parameters are always handled. Once the indexes largely change, it can be found in time to make adjustments.

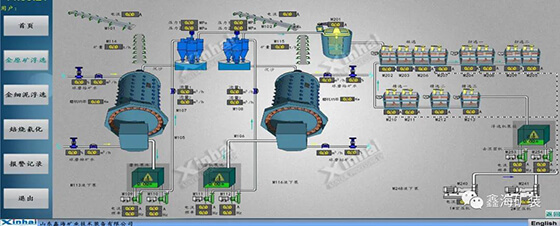

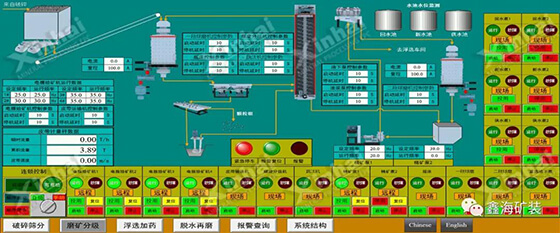

Building an automatic controlling system for the whole processing flow realizes cooperative controlling and optimized control of crushing, grinding, processing, concentrate dewatering, tailing transportation, water system, and other links in the processing flow. On the precondition of stabilizing production flow, balancing the ability and efficiency of working and guaranteeing the production indexes, reduce production costs and labor intensity, improve capacity and working environment.

For the key points such as grinding, flotation, concentrating, etc. Xinhai puts forward targeted optimizing the controlling systems, including grinding and classification optimizing systems, SABC semi-self-grinding optimizing systems, flotation foam optimizing systems, concentrating dewatering systems, etc. Further refinement and optimization, improving processing indexes starting with the details.

On the basis of relative hardware devices, Xinhai built a control cloud platform. Real-time monitoring of collecting traffic, including statistical statement of production information, hydropower energy management, consumption material management, equipment maintenance management, automatic weight management. Combining with the problem and key links during production and management, Xinhai develops diversified data analysis charts, breaking through obstacles of production manager or decision-maker, optimizing management process, and improving management efficiency.

All the online data can be checked and controlled by pc, mobile app, interactive touch screen, and other multiple terminals. It is more convenient to centralized control and production scheduling.

Collecting, monitoring, and analyzing online data. At the same time, relative production management data can be analyzed and settled online. Information pushes in high efficiency, realizing centralized control of processing plant, effectively improving mine management efficiency.

Crushing, grinding, pump station, and other workshops can be unattended. It adopts the form of centralized control + smart inspection to reduce staffing, reduce labor, reduce potential factors of plant safety accidents, and improve product safety.

Xinhai has rich experience in concentrator construction, and can closely integrate the automation system with the concentrator, and run through the entire process of concentrator planning, construction, debugging, and later operation, and the technology is guaranteed.

At present, Xinhai's automated system is already applied in part of Xinhai mineral processing EPC+M+O projects, guaranteeing high efficiency operating.

This project applies automated automatic production operation. Through a centralized control room, the operation situation of relative parameters and equipment in the processing plant can be handled. Unattended on-site implementation is applied. Inspection workers regularly inspect the operation of field equipment.

This project applies automated automatic production operation. Through a centralized control room, the operation situation of relative parameters and equipment in the processing plant can be handled. The video monitoring system is applied at key parts. The centralized control room is equipped with 2 people per shift for main inspection, three shifts for a day. Workers regularly inspect the operation of field equipment.

The automatic production operation is applied in this project. Through a centralized control room, the operation situation of relative parameters and equipment in the processing plant can be handled. The centralized control room is equipped with 2 people per shift. Unattended on-site implementation is applied. Workers regularly inspect the operation of field equipment.

As the presenter and practitioner of mineral processing EPC+M+O service, Xinhai devotes itself to provide modern, energy-saving, high-efficiency mine construction and operation solutions for clients. In the future, the mine automated progress will speed up. Xinhai will also keep breaking through, to escort the efficient development of the mining industry with new technologies and new methods, and provide customized solutions for more mines all over the world.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.