products

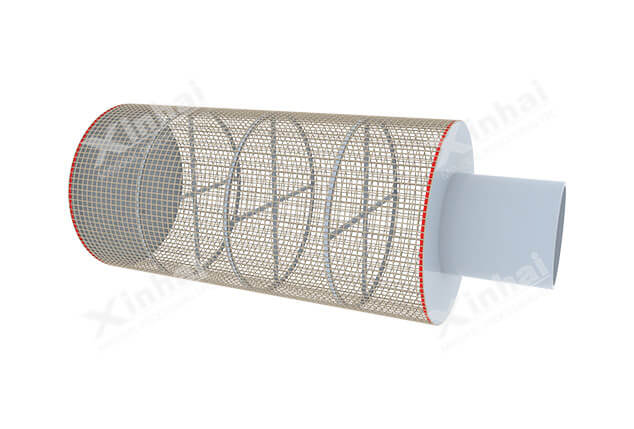

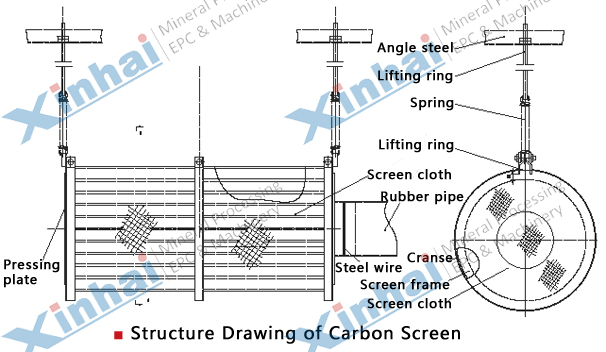

[Introduction]: An equipment for separation of carbon and slurry

[Capacity]: 100-500mm

[Improvement]: It adopts an innovative process full peat slurry cyanidation method, which can effectively avoid the occurrence of carbon blocking problems, and can obtain a higher gold recovery rate and grade.

Carbon Screen is used to separate the activated carbon with the ore pulp, which lets the pulp flow to the next leaching tank, while the carbon stays in the first tank.

| Model | Frame diameter (mm) | Frame length (mm) | Screen hole specification (mesh) | Weight (kg) |

| SY100 | 100 | 1000 | 28 | 10 |

| SY125 | 125 | 1000 | 28 | 13 |

| SY200 | 150 | 1000 | 28 | 14 |

| SY250 | 200 | 1000 | 28 | 16 |

| SY300 | 300 | 1000 | 32 | 24 |

| SY500 | 500 | 1000 | 32 | 35 |

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.