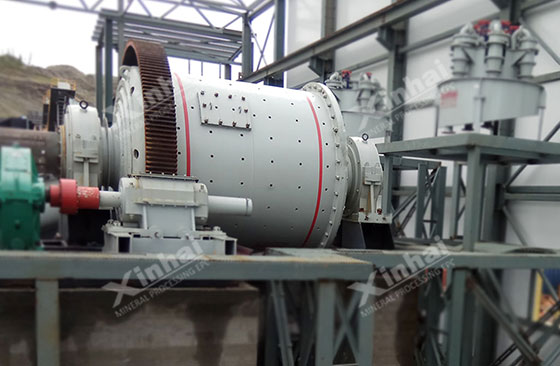

For mineral processing plant, the stable running of the ball mill is important to the production efficiency of the whole processing plant. In actual production, there are many factors influencing the operating efficiency, working life and production quality. However, the key point is the true installation and debugging. How to install and debug ball mill equipment?

The structure of ball mill equipment mainly includes feeding part, discharging part, base bearing part, cylinder part, transmission part, basis part, main motor, jack system, and electric cabinet. These modules make up the complete ball mill equipment. At present, the grid ball mill and overflow ball mill are the common types. The two types of ball mill equipment are made up of working structure and transmission structure. The main effect is to grinding materials by effective friction and centrifugal forces.

More precisely, the cylinder of ball mill equipment is mainly weld steel plate. The flange on the cylinder and a hollow shaft of feeding and discharging at either end are connected into a whole part by reaming bolt. The grinding body is installed in the cylinder. The ends of the cylinder are feeding throat and discharging throat. The device inside of the hollow shaft is the access for feeding and discharging. The inner lining can be changed.

The grinding cylinder move around the horizontal axis. During this period, it creates a higher centrifugal force. The mixed material is up to the standard height and falls in the arc of a parabola. During this process, the materials crush with each other under the influence of the cylinder and crushing rolling grinding. Under the crushing and crashing, the materials are broken. Therefore, the new materials are sent into the grinding machine and pushing forward continually, and discharging by wind or water during the running process.

Large ball mill equipment usually applies antifriction bearing, which is double row self-aligning roller bearing. This kind of bearing is common a pair with two row rollers, which is mainly to bear radial load and some axial load as well. Before the installation, there are some necessary preparations.

First, the relative installation plan should be determined and pipe equipment should be organized. The relative installation personnel should confirm and make sure the successful running of later installation. Then, the relative work should be complete, and the relative calibration should be treated seriously, which includes checking the embedded bolts and elevation consistent with the design drawings or not. If the bolt hole is out of position to a large degree, it must be rebuilt.

Second, it should be according to the corresponding standard. Reference point setting and corresponding center guide board are the fundamental basis of ball mill equipment installation and adjustment. Besides, before the installation, the equipment cleaning should be strengthened. The slushing oil and dust need to be removed before installation. To make sure the success installation, the ball mill parts should smear some dry oil, to maintain good lubrication during installation. Especially when using spirit levels, levels, steel ruler, magnet base and so on, some thin oil should be smeared on the ball mill equipment.

As for the different types and structures of different kinds of ball mill equipment, the science installation according to order should be observed by the installation personnel.

(1)The installation of ball mill base

Some parallels in different thicknesses should be prepared. During the installation, the effect of parallels is to adjust the location of ball mill equipment. Under normal situation, if the base doesn’t loose when tapping on the side, the ball mill base is up to standard.

Before the installation of the ball mill base, the analysis should be in detail and check if it is up to the relative design requirements. Observing the main bearing of the ball mill on the center line or not. The contact ratio should not be over 0.5mm, and the feeding part should be 1mm higher than the discharging part. Besides, after the elevation bolt fastening, it can be checked by transit, to check if it is on the same horizontal level with the ball mill base.

(2)The installation of the ball mill main bearing

The process of installation should make sure the normal rotation of the journal and the bearing, and good connection with each other. The two hollow shafts should have the same axial gradient, and there should be 0.5-1mm between the center shaft and bearing. The ends of the free sides should be flexible, especially in the areas with large seasonal temperature differences. The hollow shaft shoulder can easily create faults in bearing clearance under this situation. If the installation is not proper, it can cause a high temperature of bearing and some bad situations such as bearing lock.

Therefore, under normal situation, if the installation ball mill equipment is in winter, the clearance between hollow shaft outside shoulder and bearing should be smaller than that between the bearing and the inner side. It is reverse when installs in summer.

During the debugging, the motor should be sheer off first, and racing for six hours to make sure the electric pressure in the design period and the temperature of bearing about 40℃. The mill load should test run as well for 20 hours. If the ball mill equipment can run stably without noises, and with a good toothed surface connection, the ball mill equipment can be normally operated.

Besides, the bearing temperature of ball mill equipment should be less than 50℃ in debugging. At the same time, the materials should be fed into the ball mill equipment gradually during the no-load operation if the ball mill has no abnormalities. The feeding ends a higher load operation over 48 hours. The debugging ends if all the parts operate stable and without abnormal quake, the main motor with the stable electric flow in operation and up to normal level, and after operating 48 hours, there no looseness in bolts and gears.

To sum up, the installation and debugging of ball mill equipment is an important work, which influences the later production quality and efficiency. We suggest that the mine owners should install and debug ball mill by the professional personnel from mineral processing manufacturers with mineral design and research qualification, to make sure a reasonable process index and normal operation.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.