As one of the most important mineral processing equipment in the concentrator, ball mill machine plays an important role, which not only determines the technical index of the whole mineral processing flow, but also accounts for most of the investment cost and energy consumption. Therefore, it is very important to achieve the high-efficiency and energy-saving of the ball mill machine.

Xinhai Mining has been focusing on the design and development of ball mill machine for more than 20 years, and made numerous technical achievements in the research and development of ball mill machine. According to the specification of ball mill machine and customer needs, Xinhai Mining can customize the various aspects of ball mill equipment, making it achieve high-efficiency, low consumption and energy-saving.

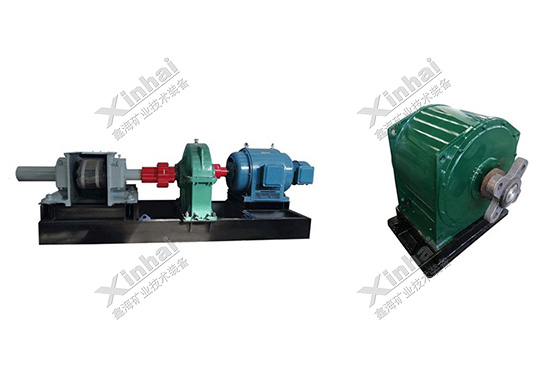

At present, the drum speed of many ball mill machines is mostly 17r/min~32r/min, and the running speed of the small ring is mostly 120r/min~200r/min. The current ball mill generally adopts the drive mode that the asynchronous motor drives the small gear ring after the speed reduction of the reducer. But problems do exist with this mode, such as low efficiency, large footprint, mass maintenance task, high vibration noise and large starting impact. Aiming at these problems, Xinhai Mining re-innovated the drive system of the ball mill machine, and replaced the original drive system with the drive system of permanent magnet synchronous variable-frequency and variable-speed motor drive system.

Starting from the system point of view, the dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine no longer only takes the motor as a standard part, but organically combines the motor, transmission mode and intelligent control to improve the motor efficiency and transmission efficiency while driving on demand, so as to achieve higher driving efficiency, and contribute to the realization of green mine.

Among them, the dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine adopt vector control variable frequency drive, the rotor adopts high-performance nd-fe-b permanent magnet materials, which is featured with compact structure, large starting torque, low speed, small start impact, high efficiency, strong reliability, low noise, energy conservation, environmental protection, convenient installation and maintenance. It is a high-efficient and energy-saving motor in line with national policy.

Compared with the existing drive system, Xinhai innovative drive system of ball mill machine has the following characteristics:

(1) Cancels the deceleration link of the reducer, which reduces the intermediate transmission link, improves the equipment operation rate, decreases the equipment operation cost, and improves the site environment with low noise;

(2) High starting torque, which makes the starting torque stable, and the starting torque is more than 1.8;

(3) High efficiency and energy-saving. The efficiency of the motor reaches the first-level energy consumption (IE4) standard, and the comprehensive power saving rate reaches 10-40%;

(4) Variable frequency speed regulation. The speed can be adjusted according to the field working conditions, so that the equipment can reach a good operating state;

(5) Vector control technology, small start-up current, no impact on the power grid and equipment;

(6) High power factor, the power factor is up to 0.94~0.99, which reduces the power supply line loss, improves the transformer efficiency;

(7) Small size, small floor area, easy to install, increases the safe channel distance.

1. Safety

The motor is equipped with windings and bearing temperature sensors to monitor the running status of the unit in real-time, which has the abilities of fault early warning, self-care in an emergency and self-protection. The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine can eliminate the deceleration links of hydraulic coupler, reducer and belt pulley, reduce the floor area and increase the space of safe passage.

2. Intelligence

The frequency converter of the dedicated permanent magnet synchronous variable-frequency and the variable-speed motor is an intelligent control device integrating feedback, control, drive, communication and protection, which is more convenient to realize the Internet of Things, remote monitoring and can improve the degree of automation.

3. Environmental protection

The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine can eliminate the deceleration links of hydraulic coupler, reducer and belt pulley, avoid the environmental pollution caused by reducer oil leakage. At the same time, it can avoid the noise caused by the wear of asynchronous motor cooling fan and reducer, greatly improve the environmental friendliness of the site.

4. Energy conservation

Improve the efficiency of the motor itself. The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine has the incomparable high efficiency and high power factor. According to the difference of original motor model, power level and load rate, the electric saving rate of the motor is 5%-10%, and there is no brush slip ring and other vulnerable structures.

Improve the transmission efficiency. The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine can eliminate many transmission links, such as the reducer, belt pulley, which can improve the transmission efficiency by 5%~15%, reduce the maintenance cost.

Reduce line loss. The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine has a high power factor of over 0.96, which can greatly reduce the line current and reduce the line loss of 2%~4% rated power.

5. Consumption reducing

The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine can save the deceleration link, save the brush slip ring structure of wound rotor asynchronous motor, cancel the high failure rate and maintain the reducer and slip rings in the long term, greatly reduce the maintenance amount and maintenance cost, eliminate the lubricating oil cost of reducer, the maintenance cost of FCB and depreciation expense of reducer.

6. Production increasing

Adopt the vector-controlled variable frequency drive can improve the starting torque, reduce the starting current, and thus reduce the impact of the power grid and ball mill equipment, improve the service life of each mechanical part. At the same time, it cancels the reducer and carbon brush slip ring structure with a high failure rate, improves the equipment operation rate by 0.5%~1%, thus increasing the operation output and increasing the profit.

7. Efficiency increasing

The ore handling capacity, ore hardness, particle size and ball mill liner wear will cause the actual speed to deviate from the designed speed. The dedicated permanent magnet synchronous variable-frequency and variable-speed motor of Xinhai ball mill machine adopt the variable frequency drive to change the operating frequency for adjusting the load speed, thus improving the grinding efficiency of the ball mill machine and greatly reducing the invalid energy consumption.

Mineral processing equipment is the key to realize the mineral processing index and economic indicator. Xinhai technology personnel of mechanical design institute can provide customers with a series of mineral processing equipment according to the equipment requirements put forward by the mine research institute and mine design institute, which can enable customers to fully enjoy the one-stop services, including "mineral processing test, mineral processing technology, equipment selection, mine design, equipment customization", combine with the complete process, increase the yield, reduce the energy consumption, prolong the equipment stable operation time, help the global customers save the investment cost and improve the beneficiation indexes.

In the future, Xinhai Mining will also insist on technological innovation with the equipment quality, takes the strong technical strength as the core competitiveness, high quality of mineral processing equipment as the quality guarantee, continuously consolidate our innovation and development ability. We will try to set the reasonable technological process for the world's mines, choose the appropriate mineral processing equipment, thus building the green mine with the ideal benefit!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.