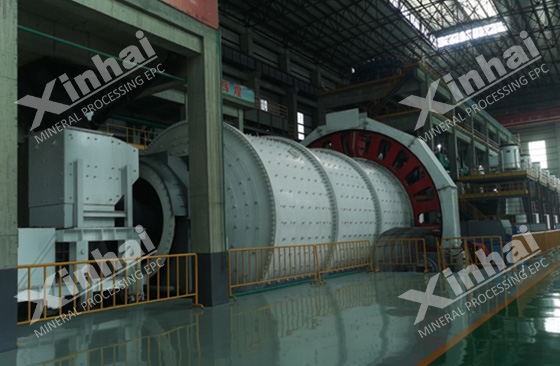

Grinding equipment is one of the important equipment used before mineral processing operation. The particle size of ore is reduced by the impact and grinding of steel ball, steel bar, gravel and other media.

Grinding operation is the equipment that continues to crush ore after crushing. The quality of grinding products will directly affect the level of the separation index. Grinding equipment is also a part of the concentrating plant with higher cost and more investment. Therefore, in the selection of grinding equipment, it is necessary to comprehensively consider various factors such as design, investment and environment before determining.

Taking a ball mill as an example, during grinding, the grinding medium and minerals in the cylinder rotate with the cylinder, and when reaching the critical height, they fall off the cylinder and crush the ore. The grinding media grinds each other during the rotation. Minerals are crushed under the combined action of impact force and abrasive force.

The movement state of grinding medium in cylinder has a great influence on grinding effect. Each combination has its appropriate critical speed, which is affected by both filling rate and rotating speed of steel balls. Because steel balls are consumables that need to be replaced regularly. Therefore, when replacing the steel ball, it needs to be filled according to its own filling rate, and it cannot be blindly filled.

There are many types of grinding equipment. According to the classification of grinding media, grinding equipment can be divided into ball mill, rod mill, gravel mill, self-grinding machine, semi-auto-grinding machine, etc. Grinding equipment commonly used in industrial production includes ball mill , rod mills, gravel mills, self-grinding mills and Ultra-fine pulverizer, etc.

According to different types of discharging, the ball mill can be divided into grid type ball mill and overflow type ball mill.

According to the water content of the medium, it can be divided into dry ball mill and wet ball mill. The classification of rod mill is similar to that of ball mill.

Ultra-fine pulverizer can be divided into Raymond mill, jet mill, vibrating mill, stirring mill and so on.

When the ball mill operates, the grinding balls and material in the ball mill bin will produce Centrifugal force and friction force. The feeding material can be grinded into fine powder under such force.

Ball mills can be widely used in the ferrous metal beneficiation, non-ferrous metal beneficiation and non-metal beneficiation. According to different method of mill discharge, they can be divided into grid type and overflow type. The Common grinding media include stainless steel balls and forged steel balls.

1.Grid Ball Mill

The grid ball mill design consists of feeding part, discharging part, rotary part, transmission part and other major parts. We install the discharging grid plate at the discharging end. Due to the continuously feeding materials, the pressure pushes slurry to the discharging grid and the grinded materials are discharged from the discharging grid plate. The inside of the cylinder is lined with a wear-resistant liner to increase the wear resistance of the ball mill.

The size of the discharge of the grid type ball mill is generally 0.2~0.3mm, which is often used on the one stage of grinding in the mineral processing plant.

2. Overflow Ball Mill

The structure of the overflow ball mill is similar to the grid ball mill. But there are differences between overflow ball mill and grid ball mill. The slurry of overflow ball mill without grid plate overflows by itself. The discharge particle size of overflow ball mill is generally less than 0.2mm, which is usually used for the second stage grinding in mineral processing.

The structure of a rod mill and ball mill is similar.

The grinding medium in the barrel of the rod mill is steel rod, whose length is not more than 7mm and diameter is between 75 and 150mm.

The common types of rod mill are the wet overflow type rod mill, end edge discharge rod mill and center-periphery row ore rod mill so on.

The rod mill is used in one stage open circuit grinding because of coarse grinding size.

Rod mill compared with ball mill:

1. Compared with the ball mill, the product size of the rod mill is more uniform and the over-crushing condition is lighter.

2. Compared with the rod mill, the ball mill has higher productivity, stronger materials adaptability and finer particle size.

When choosing ball mill or rod mill, it should be determined according to the properties of grinding materials, requirements of particle size, mode of production and others.

The lining plate protects the cylinder body from the impact and friction of abrasive body and material. The liner also influences the movement state of the abrasive body, which can enhance the grinding of the abrasive body to the material, improve the mill efficiency, increase output, and reduce the consumption of grinding medium.

Lining board material has high manganese steel, alloy steel, rubber and so on.

Installation requirements for ball mill and rod mill linings include:

1. After the lining is installed, the gap between the back-end lining and the cylinder end cover needed to be filled with the cement mortar (the grade of compressive strength is 42.5MPa).

2. The bolts at the fixed end lining shall not be filled with the cement mortar, which shall be able to rotate.

3. The lining board is generally directional, please make sure the direct at installation time.

4. Arc length of all circumferential crevices shall not exceed 315mm, and any excess shall be cut off by steel plate.

5. The gap between adjacent lining board shall not be greater than 5~10mm.

6. A partition layer should be laid between the liner and the inner surface of the cylinder. If there is no requirement, the cement mortar with a compressive strength of 42.5MPa can be filled between the liner and the inner surface of the cylinder. The excess cement mortar can be squeezed out by the solid lining-plate bolt. After the cement mortar freeze, the lining-plate bolt shall be tightened again.

7. When installing the lining plate with rubber backing board, the rubber board shall be opened before three to four weeks, making it extend freely. In the use of rubber plate, the long side of the rubber plate shall be along the cylinder axis, the short side shall be along the circumference of the cylinder.

8. Check the bolt hole of the lining plate and the geometry of the bolt, and carefully clean the flash, burr, protrusions of the bolt hole, so that the bolt can freely enter the required position.

9. The complete set of liner bolts shall be composed of bolts, dustproof washers, plain washers, spring washers and nuts; In order to prevent the leakage of ash, do not forget to use the dustproof mat when using.

10. Torque wrench shall be used to tighten the liner bolts. The liner bolts with different specifications should be tightened according to the corresponding tightening torque requirements.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.