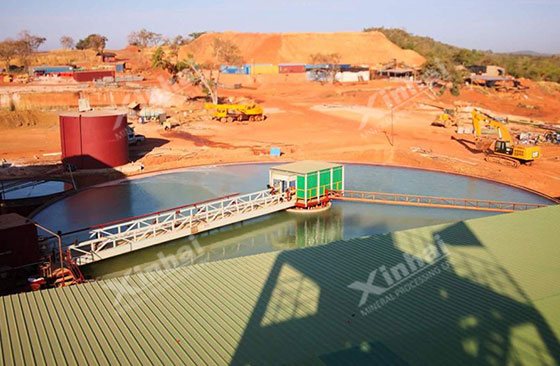

Thickener is one of the common equipments in concentrator, which can be used for dewatering, drug removing and concentration. First of all, we can understand the thickening principle of thickener. The working principle of thickener is that the slurry is divided into two parts by the gravity of solid particles, namely, clarification liquid and high concentration sediment.

How to improve the precipitation effect of thickener is the key to improve the productivity of thickener. The following five aspects are discussed to improve the thickening effect of thickener.

The size of grains in pulp is different, and the settling speed of materials in water is related to their particle size, the finer the particle size is, the slower the settling speed is, and some processes require relatively fine grinding particle size to achieve better separation index, therefore, how to make the effective settling of fine grains is the key to improve the precipitation efficiency of thickener. The settlement of fine materials can be solved by using flocculant. The flocculant can make the materials collide with each other to form flocculation, and increase the volume and settlement speed.

Before pulp into thickener, should be performed after degassing tank degassing, eliminate the bubbles of pulp, avoid ore grain adhesion on the bubble, the settlement effect affected, degassing tank used on the surface of the liquid will bubble up to the way, let the bubble volume expansion explosion, gas evolution, degassing tank design shall ensure that larger degassing space, possible removal of bubbles. When installing the degassing tank, try to maintain the level of the upper edge of the overflow baffle in the degassing tank, so that the slurry can be evenly thin-film through the baffle to facilitate gas escape.

Pulp through the feeding tube into the settlement in the middle of the thickener, on the design of the feeding mouth, down through the feeding mouth, directly into the tub after degassing of pulp level, prevent feed process gas into pulp, and at the same time to ensure that the material is steady, can add the tray on the feeder sleeve, prevent to impact into the pulp has precipitation of ore grain, avoiding the phenomenon of "flower".

The bottom structure of thickener also affects precipitation efficiency. At present, the thickener commonly used in concentrator is harrow thickener, which can be divided into center drive type and peripheral drive type. The main factor affecting precipitation efficiency of thickener is the bottom inclination Angle of thickener.In order to discharge the sediment slurry at the central discharge port at the bottom of the pool, the thickener is designed to be tapered at the bottom, and the mud is continuously scraped to the discharge port at the center of the pool by a rake scraper. The large inclination Angle of the bottom cone is conducive to increasing the height of the material compression zone and thus increasing the ore discharge concentration of the material.

The automatic control system of the thickener includes control devices for dosing, harrow lifting and bottom flow pump. The automatic control system can monitor the changes between the slurry layers in the thickener to achieve more accurate control of the thickener operation, thus improving the precipitation effect of the thickener.

The above discussion is about how to improve the thickening effect of thickener, I hope it can be helpful for all mine owners. In actual production, thickener manufacturers with rich technical experience can be consulted according to the production and economic demand to choose the thickener that meets the demand.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.