Subsurface vs. surface mining are essential yet distinct methods. Surface mining creates vast, visible pits and excels in efficiency for shallow resources. Underground mining accesses deep, rich deposits out of reach from the surface.

Debates continue: some favor surface for its cost-effectiveness, while others choose underground for depth and precision. This article compares both methods—covering strengths, limitations, environmental impact, and uses—so you can decide which best suits your mining needs.

What is Subsurface Mining?

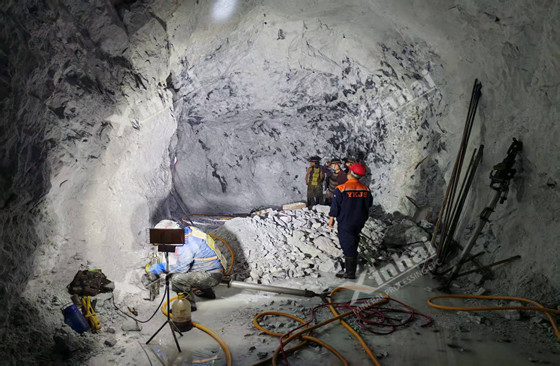

Subsurface mining, also known as underground mining, is a technique for extracting minerals from beneath the Earth’s surface. It involves excavating tunnels, shafts, and underground chambers to access valuable resources such as coal, gold, diamonds, and copper.

This method is typically employed when mineral deposits are located too deep for surface mining to be practical or economical. Unlike surface operations, subsurface mining limits land disturbance above ground but demands intensive engineering for structure, ventilation, and safety underground—highlighting a key difference in operational complexity.

What is Surface Mining?

With subsurface mining explained, we now turn to surface mining, the other primary mining approach.

Surface mining directly targets shallow minerals and rocks. Rather than excavating tunnels underground like subsurface mining, it strips away the surface layers ('overburden'), exposing minerals in open pits that so often dominate the landscape. These vast pits, unlike the hidden workings of subsurface mining, are prominent even from space.

A key advantage of surface mining over underground mining is that large machinery can operate without the space limits imposed by tunnels. This enables significantly faster and more cost-effective extraction, particularly for low-grade ore deposits where high-volume recovery is necessary to achieve profitability.

Surface mining(open-pit mining) is more open and accessible, while subsurface mining is more confined and complex. Surface methods are typically more efficient and cost-effective for shallow deposits, whereas subsurface methods are better suited for deeper, lower-grade ores and stricter environmental regulations. Below, key differences are directly compared:

1. Mining Timeline

Surface mining follows a much shorter timeline compared to other extraction methods due to its simplified workflow. Once the overburden is removed, ore extraction can begin immediately—heavy machinery quickly strips topsoil to reach minerals. In contrast to longer underground operations, most small- to medium-scale surface mining projects are completed within a few months.

Subsurface mining is far more complex and time-consuming. It requires extensive preliminary work, including digging shafts and tunnels, setting up ventilation and supports, and mapping deposits. Even well-planned projects can take years to start full production.

2. Mining Efficiency and Output

Surface mining excels in speed, whereas ore quality often lags behind. Mineral deposits near the surface typically have lower grades than those found deeper underground. Nevertheless, surface mining's ability to move larger volumes of material far more rapidly allows it to remain profitable even for low-grade ores.

Subsurface mining works more slowly but reaches higher-grade, richer mineral reserves. Deep rock often holds better deposits of gold, silver, rare metals, and hydrocarbons. Companies seeking long-term recovery often prefer subsurface mining over short-term expedience.

3. Workforce Scale and Roles

Both mining methods need skilled workers. The mining industry often lacks enough workers. This creates many opportunities for qualified people, with little competition. But workforce size and makeup differ:

Surface mining: Requires fewer workers because it relies heavily on automated heavy machinery (e.g., large trucks, excavators). Most roles focus on operating, maintaining, or supervising this equipment.

Subsurface mining: Needs a larger workforce due to the complexity of underground operations. Workers are required to maintain tunnels, monitor ventilation systems, and operate specialized underground machinery.

Common roles across both methods include:

Drillers and blasters

Geologists (for deposit mapping)

Safety inspectors

Equipment maintenance technicians

Environmental engineers

Heavy machinery operators (more prevalent in surface mining)

Ventilation engineers (unique to subsurface mining)

Subsurface miners usually earn more than surface miners. This reflects the tougher physical demands and safety risks underground.

4. Working Conditions and Safety Risks

Surface mining provides safer and more comfortable working conditions. Miners operate above ground, eliminating the risks of oxygen depletion, tunnel collapses, and exposure to toxic underground gases. The open environment also facilitates easier monitoring and response to safety hazards (e.g., equipment malfunctions).

Subsurface mining, by contrast, involves harsh and high-risk conditions:

Miners work in confined underground spaces, facing risks of tunnel collapses, rock falls, and methane gas leaks.

Explosives used to break up rock pose immediate danger if not handled properly.

Poor ventilation can lead to oxygen shortages or buildup of toxic fumes (e.g., carbon monoxide).

Underground water seepage may cause flooding in tunnels.

Overall, surface mining is markedly safer and results in significantly fewer fatal accidents than subsurface mining.

5. Costs and Profitability

Factor | Surface Mining | Subsurface Mining |

Upfront costs | Lower: Minimal underground infrastructure needed; relies on existing surface machinery. | Higher: Requires building shafts, tunnels, ventilation systems, and underground support structures. |

Operational costs | Lower: Fewer workers needed; less maintenance for surface machinery. | Higher: Ongoing costs for ventilation, tunnel maintenance, and specialized underground equipment. |

Profit drivers | Profitability depends on high-volume extraction (even for low-grade ores). | Profitability depends on high-grade ore deposits (to offset high operational costs). |

In summary, surface mining features lower entry barriers and delivers more predictable short-term profits, while subsurface mining demands higher initial investment yet promises greater long-term returns if high-grade deposits are found.

6. Environmental Impact

Neither mining method is environmentally friendly, but each causes distinct types and scales of impact:

Surface mining:

Destroys surface vegetation and topsoil, leading to soil erosion and desertification.

Surface mining creates big spoil piles, or piles of removed earth and rock. These can cause landslides or mudslides, especially when it rains heavily.

Disrupts local ecosystems by fragmenting habitats for wildlife.

Subsurface mining:

Damages groundwater systems and aquifers, as underground tunnels can alter the flow of groundwater.

Causes water pollution: Mining chemicals (e.g., cyanide for gold extraction) may leak into groundwater, posing health risks to nearby communities.

It can lead to surface subsidence (sinking of the ground above tunnels) over time, damaging infrastructure and farmland.

Both mining methods harm the environment. Surface mining causes more obvious, immediate problems on the land. The effects of subsurface mining, such as groundwater pollution, are often less visible but can last longer.

7. Common Equipment

Both types of mining rely heavily on machines. But each uses different equipment for its needs:

Surface mining equipment: Focuses on moving large volumes of overburden and ore. Key machines include:

Bulldozers

Draglines

Front-end loaders

Large mining trucks

Subsurface mining equipment: Designed for confined underground spaces and precise rock extraction. Essential machines include:

Jumbo drills

LHD machines

Roof bolters

Ventilation fans

Subsurface mining also requires additional specialized tools (e.g., gas detectors, emergency escape systems) that are not needed in surface operations.

➡Read our blog to explore the key differences between open-pit mining and underground mining.

| Pros of Surface Mining | Cons of Surface Mining |

High mining efficiency with short cycles Lower costs and low entry barriers Safe working conditions with minimal risks Simple operation and low technical barriers | Resource constraints, low ore grades Environmental damage is visible and severe High dependence on terrain |

| Pros of Subsurface Mining | Cons of Subsurface Mining |

Significant resource potential with high ore grades Minimal surface environmental disturbance High land utilization rate | Long cycles, high upfront investment High operating costs, significant risks Harsh working conditions, elevated safety risks Environmental impacts are hidden and persistent |

Torn between surface and subsurface mining? Your choice depends on your resource depth, budget, and environmental goals. Depth decides the method, cost affects returns, and sustainability reflects your responsibility. Xinhai Mining delivers quality, safety, and innovation—with tailored solutions for open-pit and underground operations.

Boost efficiency and profits with Xinhai equipment. Contact us today to get started!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.