Froth flotation is one of the most common methods in mineral processing. It plays a vital role in separating valuable minerals from unwanted gangue, boosting the grade and recovery of the final concentrate. Whether you're a mining pro, a mine owner, or just curious about mineral separation techniques, this guide breaks down everything about froth flotation—from the basics to advanced optimization tips. Plus, we'll cover the flotation machine from Xinhai Mining that can help you get the best performance. Keep reading!

Froth flotation is a process that separates minerals based on differences in their surface properties. In simple terms, it introduces air bubbles into the pulp to separate hydrophobic (water-repelling) minerals from hydrophilic (water-attracting) ones.

When air passes through the pulp, hydrophobic particles attach to the bubbles and rise to the surface, forming a froth layer that's skimmed off as concentrate. Meanwhile, hydrophilic particles stay in the pulp and get discharged as tailings. This technology started in the early 1900s for sulfide minerals and has grown into a versatile tool used across mining—from base metals to non-metals.

The froth flotation process involves a few key steps to create the right conditions for minerals to attach to bubbles and separate cleanly.

Step 1: Ore Grinding and Pulp Preparation

The ore gets crushed and ground to the right size, freeing valuable minerals from gangue. Water is added to make pulp.

Step 2: Reagent Addition

Specific flotation chemicals are added to alter mineral surfaces and stabilize the froth.

Collectors make target minerals hydrophobic.

Frothers help create and hold a stable froth layer.

Depressants and activators control which minerals float or sink selectively.

Note: Chemical choice and dosage depend on the ore's makeup—this is a custom step that needs testing, like lab-scale flotation trials, for fine-tuning.

☛ Click to see more details about gold mining chemicals

Step 3: Aeration and Froth Formation

Air is dispersed into the flotation cell's pulp, creating tiny bubbles. Hydrophobic particles stick to them and float up, building a froth layer rich in valuables.

Step 4: Concentrate Collection and Tailings Discharge

The froth concentrate is removed for further dewatering, while the remaining pulp (tailings) is pumped out for disposal or reprocessing. At its core, froth flotation turns surface chemistry differences into a smart separation method—it's all about balancing chemistry, fluid dynamics, and process control.

Froth flotation is incredibly versatile. It handles all sorts of minerals, from metal ores to non-metals in beneficiation.

| Mineral Category | Core Application Areas / Primary Purposes |

|---|---|

| Non-Ferrous Metal Sulfide Ores | Primary separation and enrichment of sulfide minerals such as copper (chalcopyrite), lead (galena), zinc (sphalerite), nickel, molybdenum, antimony, mercury, and arsenic (flotation is the core method). |

| Precious Metal Ores | Effective enrichment of gold and silver, especially for ores where they are finely disseminated in sulfide minerals. |

| Non-Metallic Minerals | Key purification methods including de-magnesitization of phosphate ores, purification of fluorite, graphite, barite, and talc, as well as fine coal separation and pyrite recovery. |

| Oxidized / Other Ores | Separation and enrichment of specific minerals such as iron ore (reverse flotation for silica/phosphorus removal), manganese carbonate ores, tungsten (scheelite), and tin (fine cassiterite). |

Froth flotation efficiency boils down to "recovery rate" (how much valuable mineral you capture) and "concentrate grade" (the purity of your final product).

Here's the thing—these metrics make or break the whole operation. Figuring out the key factors and how to tweak them is your secret weapon for better results.

Particle Size

As mentioned, particle size affects how exposed the minerals are. Particles too big (over 1 mm) won't attach well to bubbles, while ones too small (under 10 microns) can get lost in tailings—a issue called "slime coating."

★Optimization: Use controlled grinding with ball mills or rod mills for even size distribution. Lab tests like sieve analysis help nail the ideal size for your ore.

Pulp pH

pH impacts mineral surface charge and collector performance. For example, sulfide minerals need alkaline pH (8-12) for xanthate collectors to bind effectively, while oxides often prefer acidic pH (4-6).

★Optimization: Add pH modifiers (lime for alkaline pulp, sulfuric acid for acidic), and use sensors for real-time monitoring. Adjust based on cell performance—if recovery's low, pH might be off.

Reagent Dosage

Too little collector means poor bubble attachment and low recovery; too much pulls in gangue and drops concentrate grade. Frother dosage matters too—too little causes froth collapse, too much makes it too stable to skim.

★Optimization: Run lab trials to find the sweet spot for each reagent. In full production, automated dosing systems tweak amounts based on live data, like concentrate grade readings.

Aeration Rate

Bubble quantity and size dictate if minerals float smoothly—too few bubbles cut recovery, while big ones disrupt the froth layer and mess everything up.

★Optimization: Adjust with variable-speed agitators or spargers, aiming for 0.5–2 L/min per cubic meter of pulp. Cameras or sensors keep bubble diameter in the sweet spot (1–3 mm) for steady control.

Temperature

Temperature affects chemical solubility and reaction speeds. In cold spots, low temps slow collector-gangue interactions; high temps can kill frother activity.

★Optimization: Heat pulp with steam or heat exchangers in cold conditions, or cool it with jackets in hot ones. Most ores run best at 20–40°C.

Froth Height and Residence Time

Froth height sets how long mineral-bubble aggregates hang out in the cell. Too low, and separation's incomplete; too high, and it traps gangue. Short residence time (pulp dwell in the cell) also hurts recovery.

★Optimization: Tweak froth height by changing cell overflow levels. For tough ores, add more cells in series or slow pulp flow to extend time.

Success in froth flotation comes from quality, reliable gear that handles industrial-scale mining. Xinhai produces flotation machines in all sizes, up to 200 m³. Here's a rundown of the primary types and solid options for big operations:

Mechanical Flotation Cells: The go-to type, with impellers that agitate pulp and disperse air. Great for coarse particles and high throughput, like SF or BF mechanical agitation flotation machines.

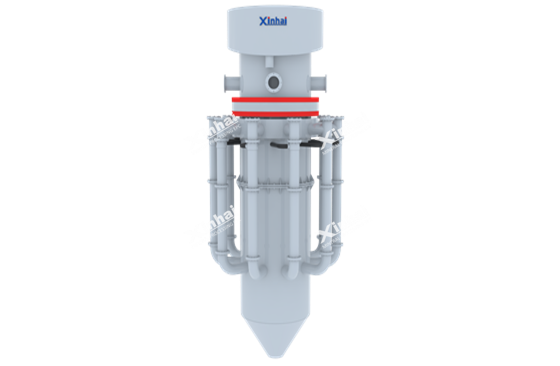

KYF Circular Flotation Cells: These efficient, energy-saving units work for all metal and non-metal ores. They're flexible to run, easy to control, stable, and simple to maintain. The round tank design speeds up on-site builds, saves space, and cuts costs.

Flotation column: Tall vertical columns use countercurrent flow (pulp down, air up) for sharper separations. They shine with fines—like gold or rare earths—and deliver high-grade concentrates.

Xinhai Flotation Equipment and Services

As a top global mineral processing EPC contractor, Xinhai offers a full lineup of flotation gear, including SF, JJF, BF, KYF, and XCF series cells tailored to capacity and ore type. Our modular steel flotation plants speed up builds, slash install costs, and boost uptime.

We handle full process design and optimization to hit max recovery with minimal energy. With experience from over 2,000 flotation plants worldwide, Xinhai doesn't just supply equipment—we deliver custom EPC solutions based on your ore specs.Contact Xinhai today to tailor your flotation system and max out plant efficiency.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.