Carbon in pulp(CIP)is one of the methods of gold extraction by cyanidation. For the CIP plant, the monovalent gold cyanide [KAu(CN)2] is sent to the carbon adsorption process after the cyanide leaching of gold-bearing material. Adopting the activated carbon to adsorb the gold directly from the cyanide slurry, which eliminates the solid-liquid separation. The gold-bearing activated carbon is used to desorb the gold and silver with the mixture of sodium hydroxide and sodium cyanide, and the activated carbon can be returned to use after the activation treatment.

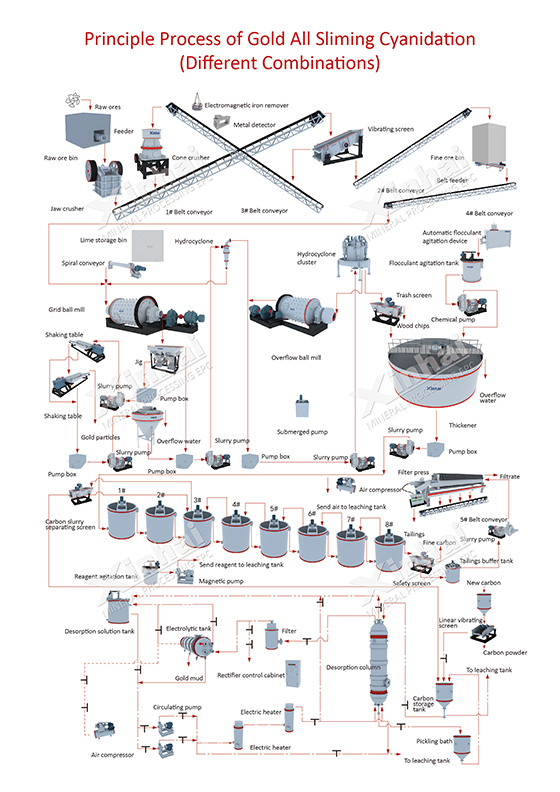

Here is the technological process of the CIP plant:

The gold-containing material is ground to the cyanidation particle size by the grinding mill, which is generally required to be less than 28 mesh, and the impurities, such as sawdust, shall be removed. It is advisable to make the concentration of leaching pulp reach 45%-50% through the concentration and dehydration.

Like the conventional cyanidation method, the agitation tanks are generally 5-8.

The cyanide slurry enters into the agitation adsorption tank (slurry tank). And the standard screen and slurry lifter can be used in the adsorption tank, which can achieve the reverse flow of activated carbon and slurry, and adsorb the dissolved gold in the slurry.

Gold loaded carbon is changed into gold mud and lean carbon in the desorption electrolysis system in the CIP plant. The high-temperature and high-pressure (150 ℃, 0.5 Mpa) can desorb 99% of the gold in just 2-6 hours. Besides, the cyanide complex ions of gold and silver in pregnant solutions have is relatively high concentration, which can be transformed into high purity solid gold by the desorption electrolysis system.

After the simple pickling and impurity removal process, the gold ingots can be obtained directly by a high frequency melting furnace. It is suggested to ensure that the gold mud fully mixes with agents in the acid pickling agitation tank, which can remove the impurities from the gold mud or acid-soluble inorganics from the solution.

After the regeneration, the lean carbon can be reused by adding a proportion of new activated carbon. After the desorption electrolysis, the coconut activated charcoal shall be pickled with dilute sulfuric acid (nitric acid), which can remove the accumulation materials (such as carbonate). Then, it is sent to a regenerative furnace to recover the adsorption activity. Finally, its iodine value can restore to 95% at least.

The gold extraction by the CIP method is mainly applicable to the gold-bearing oxidized ore with high slime content. Due to the high slime content of the ore and the difficulty in solid-liquid separation, the existing filter cannot effectively separate the precious liquid from the slag, so the conventional cyanidation method cannot get better technical and economic indexes.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.