The ore flotation process is one of the commonly used methods for phosphate ore beneficiation. To ensure good flotation effects, factors such as grinding fineness, slurry concentration, chemical system, aeration and stirring, flotation time, and flotation process selection should be strictly controlled. In addition to these factors, the quality of water added for flotation and the temperature of the slurry will also have a certain impact on the flotation effect of phosphate rock. In actual production, the appropriate phosphate ore flotation process should be selected based on the nature and characteristics of the ore and the results of the mineral processing test. The factors affecting phosphate rock flotation will be introduced below based on the above process conditions.

The degree of monomer dissociation of the ore during grinding largely determines the technical indicators of phosphate ore flotation. In the mineral beneficiation process, the useful mineral particles and gangue minerals should be completely dissociated as much as possible. Because in production practice, it will be restricted by various objective conditions, the useful minerals and gangue minerals can basically reach monomer dissociation. During the grinding process, efforts should be made to produce a small amount of continuous matter and reduce over-crushing. Phosphate rocks with different particle sizes have different effects during flotation. If the particles are too large or too fine, the recovery rate of the concentrate will be low. Because the larger the particle size, the greater the weight, and the concentrate particles tend to fall off the foam. If the particle size is too fine, the surface activity of the mineral particles will be large, which will adsorb a large amount of chemicals and non-selective mineral particles on the surface of other mineral particles, affecting the flotation process. Therefore, it is necessary to determine the appropriate phosphate ore grinding particle size through mineral beneficiation test.

(Agitation tank)

The flotation effect of phosphate rock will be affected by the concentration of slurry. During the treatment process, if the slurry concentration is too thin, the concentrate recovery rate will be low, but its quality will be high. As the slurry concentration increases, the recovery rate will also increase. Generally, after the slurry concentration increases to an appropriate level, any further increase in concentration will be detrimental to flotation. In the flotation process, a thicker slurry concentration is beneficial to flotation. However, if the concentration is too high, the ore particles and bubbles cannot flow freely, and the aeration effect is poor, which reduces the recovery rate and quality of the concentrate and prolongs the flotation time. Therefore, the appropriate slurry concentration should be selected for phosphate ore flotation. When roughing phosphate rock, the commonly used pulp concentration is 30%-35%. When flotating ores with higher particle size and slime content, the slurry concentration is 15-25%. The concentration of phosphate rock during beneficiation is generally 20%.

(Flotation reagent)

The pharmaceutical system includes the number of pharmaceutical types, dosing locations and dosing methods. The number of chemical types added to phosphate rock flotation can be obtained based on the mineral processing test results, and then verified under industrial conditions in the flotation plant, and the appropriate dosing location and method can be obtained. In order to improve the effect of the agent, it is generally necessary to stir the slurry and the agent in the agitation tank before flotation. The agitating time is about 5-20 minutes. Phosphate rock flotation often uses a mixture of fatty acid collectors and non-polar oil, which can increase the flotation speed and reduce the amount of chemicals used. In addition, it is necessary to pay attention to the pH value of the slurry, concentration of the slurry, water quality, sludge content, mixing time, etc. These factors will affect the effect of the agent.

(Flotation equipment)

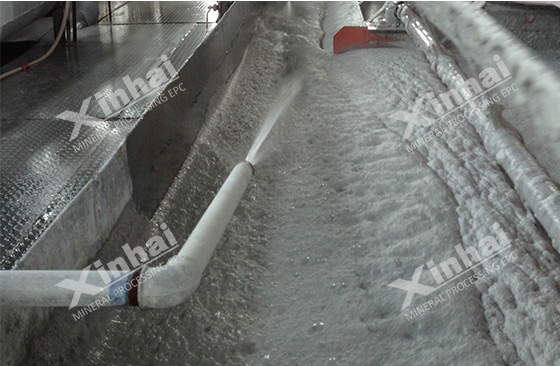

Aeration and agitation occur simultaneously during the flotation process. Aeration is to send an appropriate amount of air to the slurry to disperse it and form a large number of tiny bubbles, on which the target minerals will adhere. The purpose of stirring is to evenly suspend the ore particles and bubbles in the flotation cell. Aeration and agitation will affect flotation indicators, and strengthening aeration and agitation can improve the flotation effect to a certain extent. However, excessive aeration and agitation will cause bubble merger, which will affect the quality of the concentrate. The determination of the slurry mixing particle size and time should be based on the type and structural characteristics of the flotation machine.

(Flotation process)

Phosphate ore flotation indicators are also affected by flotation time. Under other conditions being the same, as flotation time prolongs, the concentrate recovery rate increases but its quality decreases. The flotation time is mainly affected by factors such as ore properties, ore particle size, slurry concentration, and chemical system. Roughing and sweeping of phosphate rock generally takes 15-30 minutes. The selection time needs to be adjusted according to the flotability of the mineral and the quality requirements of the concentrate.

The above are several process conditions that affect the phosphate ore flotation effect. In addition to these factors, the slurry temperature, water quality and flotation process will also affect the effect. Therefore, it is necessary to determine suitable phosphate ore flotation equipment and processes based on the characteristics of the ore and the results of the beneficiation test, thereby improving the recovery rate and quality of the concentrate.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.