There is no the same mine in the world, and every mine should choose its suitable technology scheme and equipment configuration. Xinhai Mining insists on the open-minded thoughts for every mine, customized its suitable technology and equipment, to create the ideal mine efficiency.

Currently, with the depletion of high-grade gold deposits, it is the global mainstream trend in researching the extraction technology of medium and low grade, refractory gold ore and strengthening traditional gold processing technology. At this point, Xinhai Mining has a long-term commitment to the research and revolution on gold processing method, technology, and equipment. Now Xinhai Mining has 28 kinds of innovative processing technologies for only gold.

In the following, let’s learn about a part of Xinhai innovative gold processing technologies.

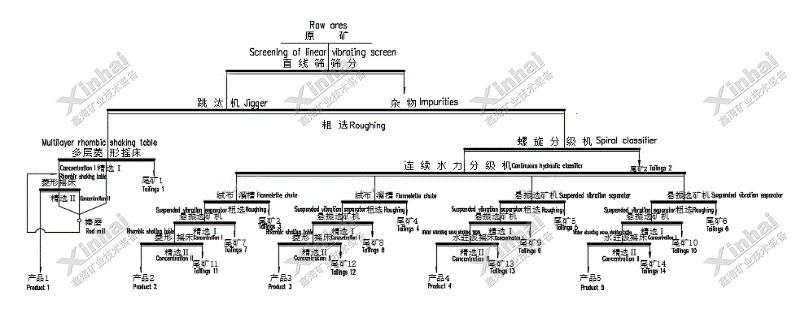

Xinhai Innovation points:

1.Xinhai Mining carries out detailed ore separability test.

2.Xinhai Mining separates according to the embeddedness, specific gravity difference, particle size, degree of mineral wealth, and degree of difficulty in mineral separation, improving the composite recovery rate of target mineral.

3.Xinhai has digested and absorbed advanced and innovative ore dressing equipment at home and abroad, improved the processing capacity and effect of single equipment, and greatly reduced the equipment's floor area.

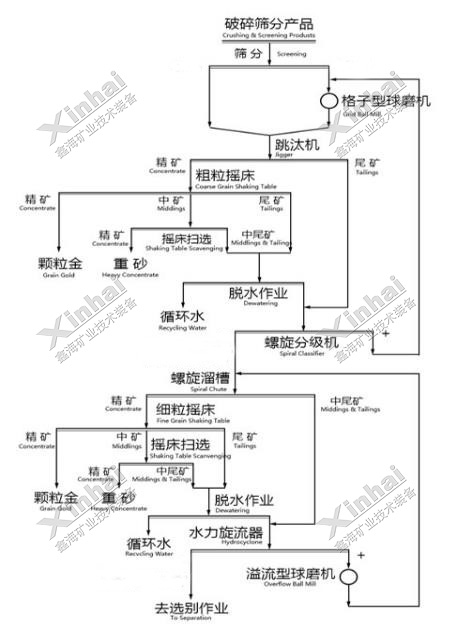

Xinhai Innovation points:

1.According to the basic principle of "recycle as soon as possible", Xinhai Mining adopts jigger + shaking table separation for coarse gold and spiral chute (or centrifugal concentrator) + shaking table separation for fine gold according to the results of original ore sieve analysis. All recoverable gold particles are basically recovered before the second stage grinding.

2.Insisting on “more crushing and less grinding” principle, Xinhai Mining adopts the high-efficiency crushing equipment (cone crusher, high-pressure grinding roller, etc.) to reduce the grain size of crushing product as possible, and sets screen before the first stage grinding. The qualified grade products are screened to the gravity separation, reducing the load of grinding and avoid the over-grinding at the same time, which is harmful to the coarse gold gravity separation. At the same time, Xinhai Mining sets hydrocyclone before the second grinding, make sure the qualified particles separating in time and entering separation operation as soon as possible.

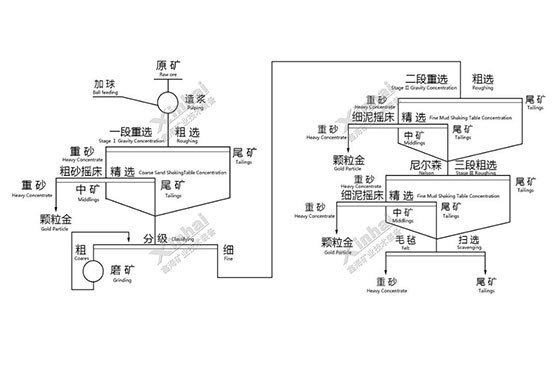

Xinhai Innovation points:

1.Till now, Xinhai Mining already completes several such projects in Africa. This kind of ore is similar in characteristic. All are laterite type gold deposits, the surface ore body weathering is serious, basically do not need to be broken, if the conventional mixing tank slurry, heavy wear impeller. For this, Xinhai Mining apples small size grinding equipment, and adding small size grinding steel balls,

2.In gravity separation, Xinhai Mining uses method of grading, separating coarse grain gold with jig and shaking table, fine grain gold with Nelson centrifugal separator and shaking table.

3. To improve the composite recovery, Xinhai Mining scraping the shaking table concentrate with Nelson centrifugal separator and felt chute.

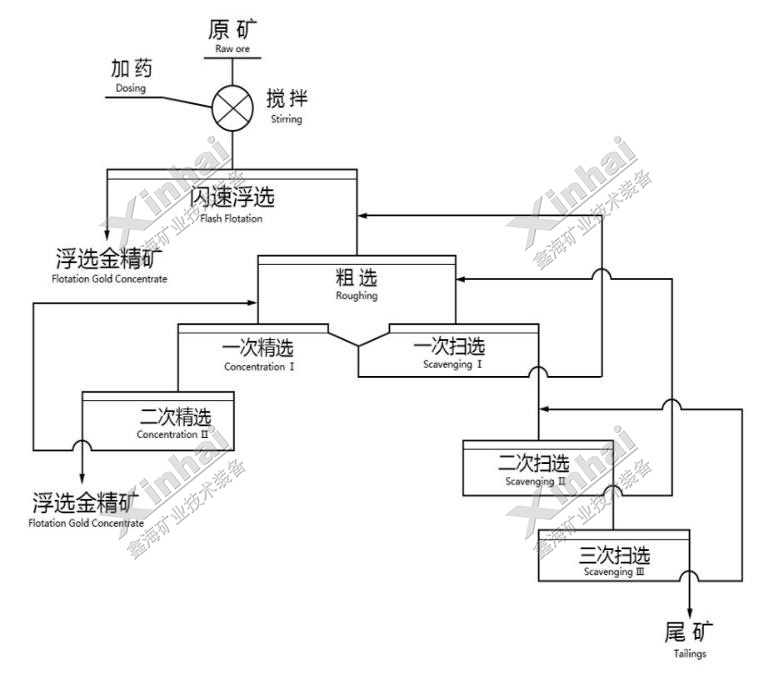

Xinhai Innovation points:

1.Xinhai Mining insists on floating high concentration and coarse grains in time, to recovery target minerals as early as possible, improving the recovery rate of valuable mineral.

2.Xinhai Mining reduces the unnecessary grinding stages to reduce the operation cost and improve the processing plant profit.

3.Xinhai Mining applies the new structure flotation equipment.

Xinhai Innovation points:

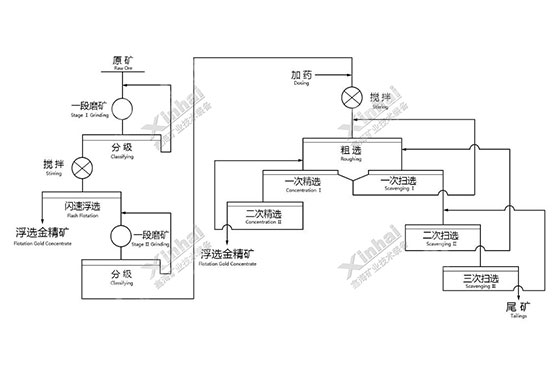

1.On the basis of above advantages, Xinhai Mining insists on the principle, adding flash flotation unit after the first stage grinding. The high grade gold concentrate of flash flotation as product with the gold concentrate from the flotation after the second grinding.

2.Xinhai innovative flash flotation technology reduces the load of the second grinding, and avoid the gold over-grinding and lost in the second grinding.

Xinhai Innovation points:

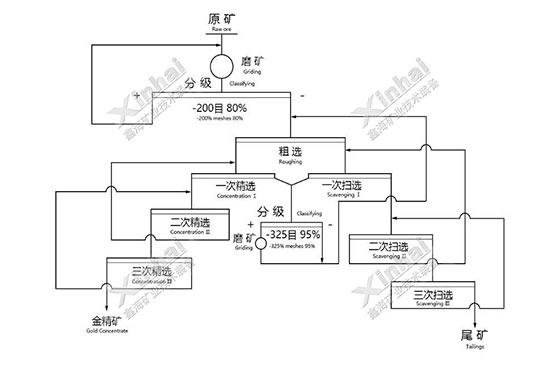

In allusion to the ore different to separate, Xinhai Mining applies ultrafine grinding + multi-stage sorting to increase the recovery rate. Xinhai Mining applies the technology of fine grinding and flotation, and the middlings regrinding and reprocessing for the first concentrating middlings and the first scavenging concentrates. Thus, it is no need for all ores to grind to -325 mesh. Most concentrates can be recovered in the grain size -200 mesh. The regrinding and reprocessing of fine grain in high grade medium ore greatly reduced the regrinding cost and improved the comprehensive recovery rate.

1.Guniea 6000tpd gold processing project

Ore character:

The ore of this project is mainly oxidized ore, 80% of which is powdery clay ore, containing granular gold. The average grade of ore is 1.0g/t, with few impurities and gold as the only recoverable element.

Xinhai solution and innovation:

One stage closed grinding and classification - gravity separation - cyanidation extraction - electrolysis desorption and melting - tailings treatment.

The 80% of ore is powdery clay ore, with water content 25-30%. Xinhai Mining resolves the problems of easy plugging and feeding, on the other hand, applied the processing flow of gravity separation and cyanidation, strengthening the gravity separation and grinding flow. A part of particles of gold are recovered in gravity separation first, reducing the gold grade in leaching operation. The agent consumption is reduced and so is the processing production cost.

To know more about the project: 【Mineral Processing Case】Guinea 6000TPD Gold Processing Project

2.Tanzania 1200tpd gold processing project

Ore character:

The ore is mainly sulfide and oxide in this project. The grade of oxide is 2.4g/t, and the gold grade of sulfide is 10.7g/t, and gold as the only recoverable element.

Xinhai solution and innovation:

All-slime cyanidation processing flow.

The grade of oxide is 2.4g/t, and the all-slime cyanidation gold leaching rate is 93.75%; gold grade of sulfide is 10.7g/t, and the leaching rate is 91.58%.

3.Malaysia 700tpd gold processing project

Ore character:

The ore mineral composition of this project is relatively simple, and the metal mineral is mainly pyrite. Non-metallic minerals are mainly quartz, calcite, mica, etc. The ore contains 4.70g/t gold, 4.63g/t silver, 20.10% iron and 20.55% sulfur. The recoverable element is only gold.

Xinhai solution and innovation:

Two stages closed grinding - thickening before leaching - leaching absorption - tailings dry stacking.

The grinding stage applies two stages closed grinding and classification. The grinding product screened by trash screen, and the undersize product flows to the thickener for thickening. The bottom flow of thickener pumps to the leaching operation. After leaching, adsorption and carbon extraction, the gold-bearing carbon products are obtained and transported to the original gold extraction plant for treatment. The leaching tailings are dehydrated by a press filter, recycled by the return water, and the dry tailings are transported to the tailings pond for stockpiling.

To know more about the project: 【Mineral Processing Case】Xinhai Mining – Malaysia 700tpd Gold CIL Project

4.Zimbabwe 700tpd gold processing project

Ore character:

The gold grade of raw ore is up to 6g/t in this project.

Xinhai solution and innovation:

One stage grinding - two stage classification closed grinding - gravity separation - cyanidation - electrolysis desorption - melting - tailings dewatering.

Considering that the gold grade of raw ore is as high as 6g/t, in order to avoid the loss of granular gold in the leaching system, a gravity separation system is added to the grinding grading circuit to recover granular gold as soon as possible, which provides a guarantee for the ideal gold recovery rate.

5.Tanzania 600tpd gold processing project

Ore character:

The gold disseminated grain size is fine in ore, with monomer gold more than 30%, and the particle size of more gold is less than 13μm.

Xinhai solution and innovation:

Two stage and one closed circuit crushing and screening - two stage closed circuit grinding - CIL and high-temperature high-pressure electrolysis desorption - high frequency furnace melting gold - tailing press filtering and dry stacking

Due to the change of ore properties in this project, the single gravity separation process adopted by the original weight separation plant is difficult to effectively recover the gold mine, and the technical indexes and economic benefits of the plant are quite unsatisfactory, so we decided to entrust xinhai Mining to build and transform it. On the basis of the original weight dressing plant, xinhai Mining adopts CIL process of gold mine, and the final gold leaching rate reaches 91.64% and carbon adsorption rate reaches 99.00%. The tailings dry drainage process makes the water content of tailings filter cake only 20%.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.