Non-metallic mineral resources are mainly used in industrial raw materials, building materials, chemical materials and other fields. With the advancement of industrialization and urbanization, the demand for non-metallic minerals continues to increase, especially in the fields of new energy, new materials and environmental protection, which has led to a rapid growth in the demand for some key non-metallic mineral resources. Therefore, the development and utilization of non-metallic mineral resources have received great attention. Xinhai Mining has always practiced the service concept of "Optimal Solutions for Your Mine", and continuously promoted the innovation and promotion of non-metallic mineral processing technology and equipment. The following will introduce you to some successful non-metallic mineral processing projects completed by Xinhai Mining.

The client commissioned Xinhai Mining to provide a complete set of equipment manufacturing and procurement, installation and commissioning services for the project. The final product of the project is required to be secondary flat glass sand. The process flow designed by Xinhai is scrubbing-classification-scrubbing-classification-magnetic separation. The project has been installed and entered the process commissioning stage. In the first batch of qualified products SiO2 grade is 96.5%, Al2O3 grade is 2.05%, and Fe2O3 grade is 0.09%.

A concentrator in Shanxi commissioned Xinhai to study its quartz sand beneficiation project, and conducted comprehensive condition tests by on-site sampling to develop a reasonable process plan for the customer. Through the test, the technical and economic indicators of the "raw ore magnetic separation-scrubbing process" and the "raw ore magnetic separation-flotation-scrubbing" process were compared, and the project chose to adopt the "raw ore magnetic separation-scrubbing process". This process can obtain quartz concentrate with a yield of 84.03%, SiO2 grade of 99.64%, Al2O3 grade of 0.093%, and Fe2O3 grade of 0.038%. The customer is very satisfied with the result.

The brand influence and service quality of Xinhai Mining Equipment have been recognized by customers, and Xinhai Mining Equipment has been commissioned to provide customized mining industry chain services including mineral processing tests, mine design, complete equipment manufacturing and procurement, installation, commissioning and delivery for the project. The CaF2 content in the original ore of this project is 42.10%, and the SiO2 content is 43.43%. The gangue minerals are mainly quartz, sericite and dolomite. Fluorite minerals and quartz minerals have a close symbiotic relationship, and the embedded particle size is relatively fine. Aluminum-containing minerals have an adverse effect on flotation. Xinhai Mining has determined a suitable flotation process for it through mineral processing tests.

As one of the important flotation plant projects undertaken by Xinhai Mining, Xinhai Mining provides customized full-industry chain services for the project, including research and design, complete equipment manufacturing and procurement, commissioning and delivery, and engineering management. Xinhai designed the process flow as follows: raw ore - coarse crushing - fine crushing - primary grinding - coarse flotation - coarse and fine re-grinding - fine flotation - fine sweep flotation, and then after concentration and filtration, bagging, the final fluorite concentrate product is obtained. During the operation of the project, the team of Xinhai Mining stayed at their posts, did the corresponding work well, and overcame various unfavorable conditions. The project has now been successfully put into operation.

Xinhai Mining provides EPCM+O services for this project, including mineral processing process design, equipment manufacturing and procurement, and on-site installation and commissioning. Xinhai's design solution is a grinding-gravity classification process. At present, this project has entered the production stage steadily, and the mineral processing economic indicators and benefits have reached the customer's expected goals. The customer sent a "thank you letter" to Xinhai Mining, praising the technical engineers of Xinhai Mining for their supervision work, meticulous professionalism and high sense of responsibility.

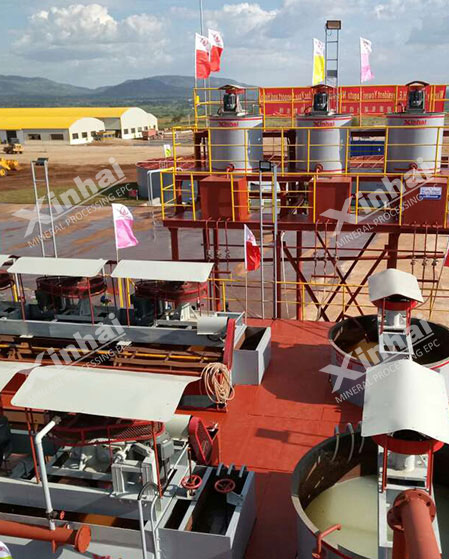

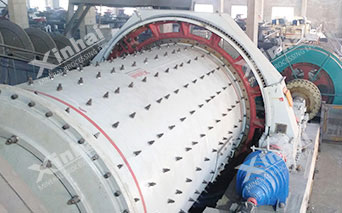

This project is a cooperative project of China-Uganda Energy Industrial Park. Xinhai Mining completed the project commissioning work in one go within a limited time. The raw materials of this project are high-phosphorus tailings from the magnetic separation plant (-200 mesh accounts for 50%). The main process flow is: the raw materials are transported to the high-concentration stirring tank for slurry mixing, and the slurry after stirring and mixing is transported to the original ore desludging cyclone for desludging. The ball mill, pump, and grading cyclone form a closed-circuit grinding system. The flotation process is designed as a positive flotation process with one roughing, one sweeping, and two fines. The flotation concentrate is transported to the concentrate dehydration system for dehydration, and the dehydrated product is phosphate concentrate; the flotation tailings are transported to the tailings dehydration system for dehydration, and the dry tailings are transported to the tailings pond by dump trucks for storage; the dehydrated filtrate is returned to production for recycling.

According to the nature of the raw ore of the project, the project uses flotation technology to process the raw graphite ore, with a daily processing capacity of 3,000 tons. Xinhai Mining customizes the main and auxiliary equipment of the production line for it to meet its process requirements.

The main minerals of the original ore of this project are graphite grainstone, followed by graphite schist, and its important useful mineral is medium flaky graphite. Xinhai Mining provides EPCM+O services for this project, and the design process is: one stage roughing selection, two stages scavenging selection, ten stages of concentration, two stages of closed-circuit crushing-one stage of closed-circuit grinding classification-flotation process. In order to obtain high-carbon graphite concentrate, the graphite concentrate is wet screened, the -140 mesh concentrate yield is 3.68%, and the fixed carbon content is 95%; the graphite recovery rate of the -140 mesh concentrate is 10.72% and 91.46%. Due to the perfect overall process flow, simple reagent system, and advanced project indicators, the recovery rate of graphite concentrate reaches 92%.

The non-metallic mineral resources in the world are rich, but unevenly distributed and affected by a variety of factors. Reasonable and efficient non-metallic mineral processing technology is of great significance to improving resource utilization, product quality, reducing costs and environmental protection. With the continuous advancement of technology, non-metallic mineral processing technology will play a more important role in the future and promote the sustainable development and utilization of mineral resources.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.