Fluorite (fluorspar) is a mineral mainly composed of calcium fluoride (CaF2), with a cubic crystal structure, a Mohs hardness of 4, a variety of colors and transparency ranging from transparent to translucent. Due to its excellent properties, it is widely used in traditional and emerging industries such as metallurgy, chemical industry, building materials, ceramics, aviation, refrigeration, and medicine. It is a strategically significant non-metallic mineral resource. With the continuous development of social science and technology and economy, the demand for fluorite in various industries is increasing. It is of great significance to study how to efficiently recycle fluorite ore. This article will introduce you to the commonly used fluorite beneficiation technology, beneficiation reagents, beneficiation influencing factors, and Xinhai Minning typical fluorite beneficiation plant case, to help you better understand the beneficiation of fluorite ore.

The selection of fluorite ore dressing method needs to consider factors such as ore type, ore composition, ore grade, etc., and select economically reasonable and technically feasible process methods for ore dressing. At present. The fluorite ore dressing processes commonly used in ore dressing plants include: crushing and grinding, gravity separation process, flotation process, magnetic separation process, dehydration and drying, details are as follows:

Crushing and grinding are the primary processing steps of fluorite ore beneficiation. The main purpose is to reduce the particle size to the level required by subsequent processes to improve beneficiation efficiency and the grade of the final product.

Jaw crusher: an ideal equipment for the primary crushing of fluorite ore. It crushes large pieces of ore into smaller particles through extrusion, which is convenient for subsequent grinding processing.

Impact crusher or cone crusher: mainly used in the fine crushing of fluorite ore, which can further reduce the particle size of the ore and provide suitable feed for grinding operations.

Ball mill:It is the main equipment for fine grinding of fluorite ore. It impacts and grinds the ore through the grinding medium to further refine the ore particle size to the particle size required for mineral processing.

Autogenous mill or rod mill: In some cases, the crystal structure in the ore is required. The use of autogenous mill or rod mill can reduce the damage to the mineral crystal and improve the purity and quality of the product.

In actual production, the crushing equipment and grinding equipment can be reasonably configured and adjusted to ensure the efficient operation of the entire crushing and grinding process. The use of advanced automatic control technology can also realize real-time monitoring of the equipment operation status, reduce equipment energy consumption and increase processing capacity.

Flotation operation is a beneficiation method widely used by fluorite ore beneficiation plants at home and abroad to obtain high-quality fluorite concentrate. Flotation can be used for various types of fluorite ores. Fluorite flotation is a process that uses the difference in surface hydrophobicity between fluorite and gangue minerals such as quartz and calcite to make fluorite adhere to bubbles and float out of the pulp during the flotation process. During the flotation process, the pH value of the pulp is adjusted by adding reagents to change the properties of the mineral surface to separate the fluorite.

The types of flotation machines commonly used for flotation of fluorite include mechanical agitation flotation machines and aeration agitation flotation machines.

Flotation agents play a key role in fluorite flotation, mainly including collectors, inhibitors and frothers.

Collectors: Commonly used collectors are fatty acid agents, such as oleic acid, oxidized paraffin soap, etc. These agents can enhance the hydrophobicity of fluorite under alkaline conditions, making it easier to float with bubbles.

Inhibitors: Used to inhibit the flotation of gangue minerals. Commonly used inhibitors include water glass, sodium carbonate, etc., which are mainly used to inhibit the flotation of quartz and calcite, and increase the separation effect between fluorite and gangue minerals.

Frothing agents: Commonly used frothers include pine oil, butanol, etc., which can produce small and uniform bubbles in the slurry, which helps to improve the flotation effect.

The fluorite gravity separation process uses the difference in specific gravity between gangue minerals and gangue minerals such as quartz to separate fluorite from impurity minerals by gravity. Because the density of fluorite is about 3.0-3.2g/cm3, which is higher than the density of gangue minerals, the gravity separation method can achieve separation without reagents or with a small amount of reagents. Common equipment for fluorite are jigs and shakers.

Jigs: pulsating water flow is used to separate the mineral particles according to the density difference. The high-density fluorite particles are deposited at the bottom, and the low-density gangue particles float on the top, thereby achieving mineral separation. Jigging equipment is mainly used to process coarse-grained ores.

Shaking table:The slurry reciprocates on the inclined bed surface, and minerals of different densities are layered according to density and particle size. The dense fluorite moves downward, and the light gangue minerals move to the other end. The shaking table is more suitable for processing medium and fine-grained ores.

When fluorite contains associated iron impurities (magnetite, hematite or limonite), magnetic separation can effectively treat such ores. Magnetic separation can remove these magnetic minerals at an early stage, reducing the burden of subsequent flotation or re-selection operations. Generally speaking, fluorite needs to be crushed and ground to a suitable particle size, and then medium and low intensity magnetic separation equipment is used to remove iron impurities and improve the purity of the fluorite. Magnetic separation is generally suitable for fluorite resources with high iron content and more impurities.

The dehydration process of fluorite concentrate mainly consists of three key processes: concentration, filtration and drying.

Concentration stage: remove moisture from fluorite concentrate by gravity or flotation, while increasing the concentration of fluorite in the pulp and reducing the burden of subsequent treatment.

Filtration stage: use filter cloth or filter medium to further remove most of the remaining moisture in the pulp, usually through vacuum filter, belt filter or filter press and other equipment to complete.

Drying stage:After drying, the moisture in the concentrate is further reduced to the specified moisture content for storage, transportation and subsequent use. Drying usually uses a rotary dryer or fluidized bed drying equipment to evaporate the moisture in the concentrate by heating and ventilation, and finally obtains a dry fluorite concentrate that meets the quality requirements.

This three-step process can not only improve the quality and yield of fluorite concentrate, but also ensure the transportation and storage stability of the concentrate product.

During the fluorspar flotation process, multiple factors will affect the separation effect and flotation efficiency of minerals. The following are the main influencing factors and their brief descriptions:

pH value: The pH value has a significant impact during the flotation process. Usually, the flotation effect is better under alkaline conditions, because some impurity minerals can be suppressed under alkaline conditions and the separation accuracy of fluorite ore can be improved.

Type and dosage of reagents: Commonly used reagents for fluorite include collectors such as fatty acids and regulators such as water glass. The dosage will directly affect the flotation selectivity of the mineral and the stability of the slurry.

Temperature: The temperature during flotation will affect the activity of the reagent and the concentration of the slurry. When the temperature of the slurry is increased appropriately, the solubility of the reagent and the activation of the mineral surface can be improved, thereby improving the flotation index of fluorite ore.

Slurry concentration: Slurry concentration mainly affects the stability of flotation foam and flotation efficiency. Controlling the slurry concentration can ensure better separation of fluorite ore and gangue minerals.

Stirring intensity: Appropriate stirring intensity is to help the agent distribute evenly in the slurry. If the stirring intensity is too high, it will destroy the foam box minerals and reduce the flotation efficiency.

During the fluorspar flotation process, multiple factors will affect the separation effect and flotation efficiency of minerals. The following are the main influencing factors and their brief descriptions:

In the grinding process of fluorite ore, the control of grinding fineness and the selection of classifying equipment will directly affect the flotation effect and the quality of concentrate. The following are the key points about the selection of grinding fineness and classifying equipment:

Grinding fineness: Fluorite flotation usually requires the mineral particles to reach a moderate fineness to facilitate the full contact between the reagent and the mineral surface. Generally speaking, the grinding fineness is more suitable at around 200 mesh (0.074mm). Too fine particles may cause ore slime problems and affect flotation selectivity; while too coarse particles may lead to incomplete flotation separation, thereby affecting the recovery rate and concentrate grade of fluorite.

Selection of classifying equipment: Commonly used classifying equipment includes hydrocyclones and spiral classifiers. Hydrocyclones are suitable for processes that require high-efficiency classifying, which can quickly separate fine particles and prevent the slurry from being too fine or too coarse. The spiral classifier is suitable for controlling the uniformity of the particle size of the grinding product and reducing over-grinding.

Reasonable selection of grinding fineness and classification equipment can not only help improve the recovery rate and grade of fluorite concentrate, but also effectively control the grinding cost.

With the advancement of science and technology and the increasing demand for high-purity fluorite in various industries, the fluorite ore dressing industry will usher in more innovations and opportunities in the future. Intelligent, automated and green environmentally friendly technologies will be widely used in the beneficiation process, which will improve mineral recovery and reduce production costs while reducing environmental impact.

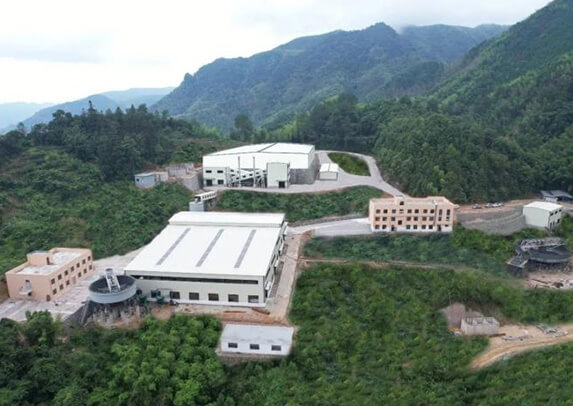

Xinhai Mining is committed to achieving technological innovation and production optimization in the field of fluorite ore dressing to meet the growing market demand and increasingly stringent environmental protection requirements. By increasing investment in the research and development of advanced beneficiation equipment and processes, improving the level of automation, and adopting intelligent control systems, the efficiency and precision of the beneficiation process can be achieved. At the same time, we will keep up with the trend of green mine development, optimize resource utilization, reduce waste emissions, and focus on the research and development of environmentally friendly reagents to reduce the impact of the beneficiation process on the environment. Xinhai Mining will also further expand the international market, actively participate in the global supply chain, promote industrial upclassifying in the field of fluorite ore dressing, and continue to provide customers with high-quality, low-cost fluorite products.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.