solutions

[Introduction]: Magnetic separation places the leading position in iron ore separation. For weak magnetic and lean iron, Xinhai adopts gravity separation, magnetic separation, flotation, and roasting magnetic separation used for strong magnetic iron ore and magnetic separation.

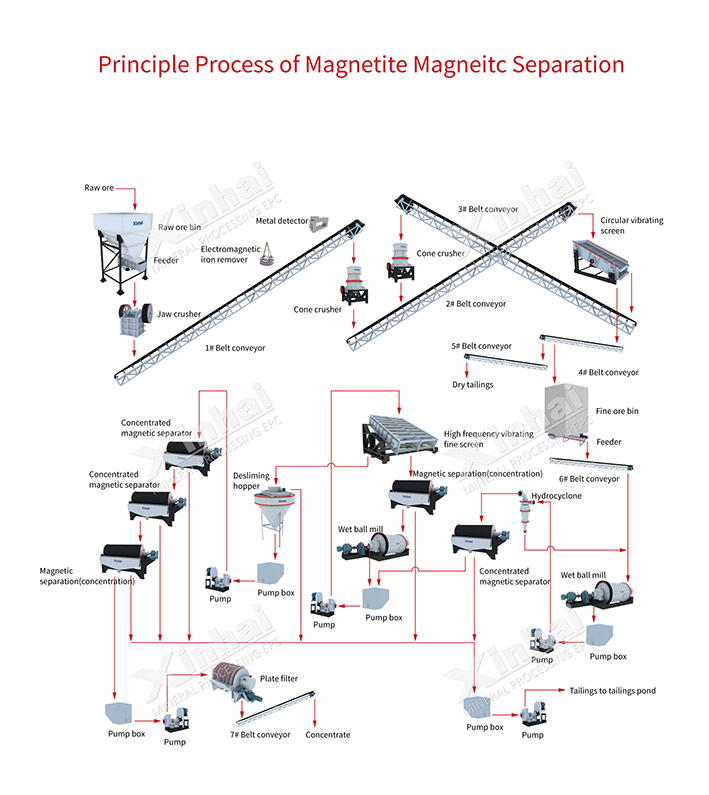

[Improvement]: Magnetite separation production line is used to single magnetite with simple ore properties.

According to the ore magnetism, the suitable mineral processing technology is chosen. Magnetic separation is the main processing technology, cooperating with gravity separation, flotation, roasting magnetic separation as joined process method.

It is mainly used for low-grade magnetite ore. As for the strong ore magnetism, easy to grind and separate, the coarse-grained magnetite common uses two-stage grinding, othervise the multiple-stage grinding flow is used. At present, Xinhai fine grinding technology can increase 61% concentrate grade to 67%.

After magnetic roasting, weak magnetic ore can be separated by strong magnetic separation.

In the flow of two-stage grinding stage separation single weak magnetic separation, the fine grinding on-screen regrinding re-processing technology is added. It can separate the dissociated fine-grained minerals, reduceing over-grinding and increasing capacity. The concentrate grade can be increase about 2%.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.