Quartz sand is the main raw material for glass, casting, ceramics and fireproof materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical industry, plastics, rubber, abrasives, filter materials and other industries. In the processing process, it needs to be broken and ground into fine particles first, but some quartz sand contains mud impurities, which seriously reduces the efficiency of quartz sand purification and causes economic losses. In order to obtain high-purity quartz sand, mud removal and purification are very important. So how to effectively remove mud from quartz sand containing mud impurities? It can be done by water washing. Let's learn about quartz sand washing methods and equipment.

Water washing is the process of removing clay materials from quartz sand. It is usually set before crushing, gravity separation, magnetic separation and flotation operations to eliminate the influence and harm of ore mud on these operations, so as to improve the operation efficiency and obtain good separation indicators. The process is: the large pieces of quartz raw materials are evenly and continuously transported to the jaw crusher for coarse crushing by the vibrating feeder; the coarsely crushed quartz is fed to the cone crusher for medium and fine crushing; then the finely crushed quartz is transported to the sand making machine for sand making and shaping; then the treated quartz sand is screened by the vibrating screen to sort out a variety of different specifications. Those that meet the particle size requirements are transported to the sand washing machine for cleaning, and those that do not meet the particle size requirements are returned to the sand making machine on the upper layer for reprocessing. In the finishing production line, belt conveyors are usually used to connect various equipment. This forms a closed-loop quartz sand crushing and screening system. The finished product processed by the quartz sand washing production line has uniform particle size, reasonable grading, high cleanliness and reliable quality.

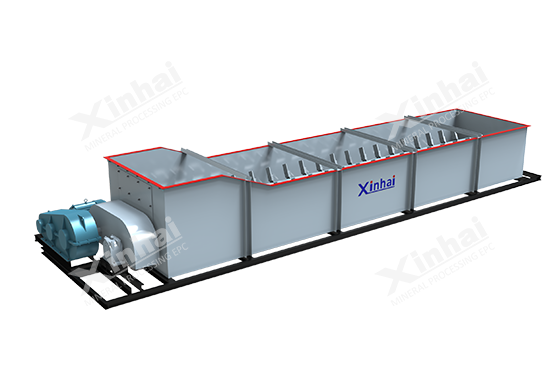

Common quartz sand washing equipment can be divided into two categories: spiral ore washing machine and cylindrical ore washing machine.

1. Spiral ore washing machine

There are two types: single spiral sand washing machine and double spiral sand washing machine. The main difference from the other two is that the equipment has a spiral device system, which is used to stir the quartz sand through the spiral device to achieve the effect of cleaning and screening. The equipment is practical and flexible, the weir plate can be adjusted, and it is high-energy and durable.

2. Cylinder ore washing machine

There are two types: cylindrical type and screen bar type. The screen bar type can divide the washed material into two grades of +40mm and -40mm products. -40mm can be further scrubbed by a double spiral trough ore washer, and the material can be divided into two grades of +2mm and -2mm products. The washing efficiency can reach about 98%.

In addition to water washing equipment, there are also scrubbing machines for removing impurities on the surface of quartz sand, such as high-efficiency stirring scrubbing machines and spiral trough scrubbing machines. During operation, the rotation of the impeller is mainly used to drive the slurry to rotate, so that the sand particles collide and rub against each other, thereby achieving the purpose of removing the mud and sand on the surface of the quartz particles.

The above is an introduction to the quartz sand washing method and equipment. In actual ore dressing plants, the quartz sand washing process and equipment should be determined according to the mud impurities contained in the quartz sand. They cannot be selected blindly. The better the washing effect, the higher the efficiency of later ore dressing and purification. Therefore, it is recommended to conduct ore dressing test analysis first, and design a suitable quartz sand washing process and purification process through analysis.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.