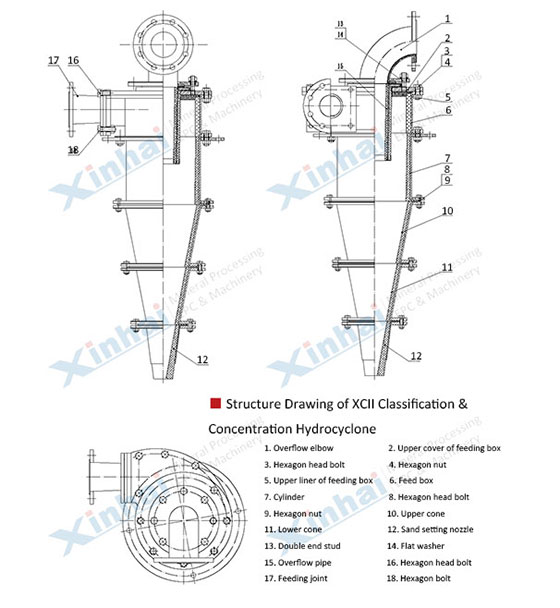

Hydrocyclone is an effective separation device that carries on two-phase fluid separation by using the centrifugal force field. It is a non-motion separation device composed of the upper cylinder and the lower cone.

When the pulp is shot in the cylinder through the feeding tube in a tangent, involute or spiral way, the mixture of medium and particles produces the centrifugal field caused by rotating, the particles (or liquid phase) with different density produce the different trajectories. Under the action of centrifugal force, medium resistance and force field, the coarse particles and heavy particles moving towards the periphery, and are discharged from the spigot through the cone-shaped body; the fine particles and low-density particles (or liquid phase) move toward the center and are discharged by the overflow pipe, finally the classification of solid particles and the separation of fluids with different densities are realized.

In the ore dressing, hydrocyclone is mainly used in the classification of grinding circuit, especially the classification in the fine grinding. Besides, hydrocyclone can be applied in the desilting and thickening operation.

Different applications propose various requirements for the technical parameters of the hydrocyclone, including structure parameters, operating parameters, feeding properties. What's more, the technical parameters are correlated and constrained mutually, they are not easy to adjust and control, which requires that we must understand each technical parameter before selecting the hydrocyclone.

The diameter of the cylinder is the main standard to distinguish the size of hydrocyclone, which has a certain ratio with other spare parts. Increasing the diameter of the cylinder can improve the processing capacity of the hydrocyclone, but the overflow particle size will become coarser at the same time. When processing the fine materials with large handling capacity, the cyclone unit composed of several small cyclones in parallel can be adopted.

The height of the cylinder has a significant influence on the residence time of slurry and classification efficiency in the cyclone. When the overflow pipe is inserted into a certain depth, increasing the height of the cylinder can lengthen the separation time, reduce the separation granularity and improve the separation efficiency, but also reduces the output and increases the energy consumption. In general, the effect is better when the height of the cylinder is 0.6-1.0 times of the diameter of the cylinder.

Generally, the diameter of the feed port is 0.13-0.25 times of the diameter of cyclone. Appropriately increasing the diameter of the feed port can improve the processing capacity of the hydrocyclone, but the classification efficiency will be reduced to some extent at the same time. In general, the cross-section shapes of the feed pipes are mostly circular and rectangular, and most of them are rectangular. The configuration mode is that the long side is parallel to the axis of hydrocyclone, while the short side is perpendicular to the axis of hydrocyclone.

In the early stage, the structural form of feed pipe and its connection with the cylinder body were mostly tangential, which had the advantages of simple structure and convenient configuration, but the flow pattern changed suddenly and the loss of on-way resistance was large, which was easy to generate turbulence. Later, involute feed pipe was widely adopted, which reduced the energy consumption, increased production capacity and improved the separation efficiency.

The overflow pipes are mostly circular, and their diameter is usually 0.2-0.3 times of the diameter of the hydrocyclone. Its main function is to draw out the overflow product smoothly and constantly. Increasing the diameter of the overflow pipe, the overflow flow will be increased, but the overflow particle size will also be coarser, and the concentration will be increased while the fine particle decreases.

Usually, increasing the output diameter, the overflow is reduced, and the overflow is finer, the output capacity is increased, the concentration is lower, and the fineness is increased, but the processing capacity of hydrocyclone is not significantly affected. Reducing the output diameter, the discharging capacity of the sand setting is reduced. If too small, the coarse grains will stock at the top of the cone, so that appear jams phenomenon.

In general, the diameter of the output should ensure that the sand is discharged in an umbrella shape, and the included angle of 20°-30° is the ideal value. The diameter of output is usually 0.07-0.1 times of the diameter of the overflow pipe.

If the overflow pipe is inserted too shallow, the short-circuit flow rate will increase, the separation time will be shortened, and the content of coarse grain in the overflow product will increase, and the content of fine grain in the output product will increase, but the classification efficiency decreases. If the overflow pipe is inserted too deep, the coarse particle size at the bottom will enter the overflow, which reduces the classification efficiency of the hydrocyclone. In general, the insertion depth of the overflow pipe should be 0.5-0.8 times of the height of the cylinder.

Increasing the cone angle of the cylinder will decrease the height of cyclone and increase the average radial velocity of the slurry. At the same time, because the flow resisting of the cone is increased, the upward flow velocity of the slurry will be increased corresponding, which leads to the overflow particle size become coarser. Therefore, it is suggested to adopt a large cone angle (30°-60°) to separate the coarse-grained particles, and adopt a small cone angle (15°-30°) to deal with mud removal.

The feed pressure has a direct influence on the processing capacity and separation particle size of the hydrocyclone. Normally, the feed pressure should be maintained at 49-157 kPa. Increasing the feed pressure can reduce the classifying granularity and increase the processing capacity. But at the same time, it can also significantly increase the power consumption and the wear of cyclone. When the hydrocyclone works normally, the feed pressure should maintain a stable value.

The pulp properties mainly include density, particle size and pulp concentration. At the same slurry concentration, the higher the density of ore, the finer the grading granularity.

When the slurry concentration is large and the mud content is high, the viscosity and density of the pulp will increase accordingly, which increases the movement resistance of the particle size and makes the grading particle size coarser. The ideal slurry concentration should be determined by mineral processing test according to specific production condition.

To sum up, the hydrocyclone operator can timely adjust the operation by adjusting the slurry pressure, changing the output diameter, slurry concentration, cone angle, the size of feed pipe and overflow pipe and the composition of particle size.

In addition, it is recommended to purchase the hydrocyclone from the professional and regular hydrocyclone manufacturers and consult the professional cyclone technicians according to the actual production conditions, so as to achieve a win-win situation of technical indicators and economic benefits.

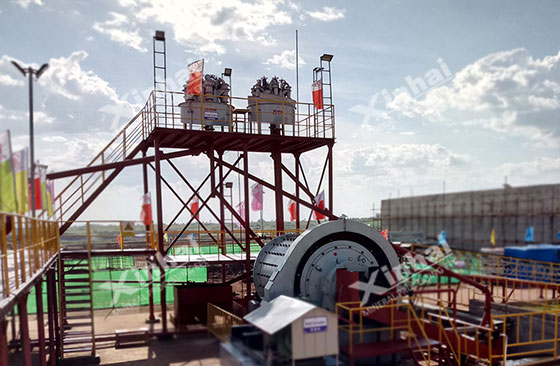

Application of Xinhai Mining hydrocyclone

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.