Mongolia is located in Northeast Asia, and is closely connected to my country in the east, south and west, with a border line of 4,710 kilometers. Mongolia has a complex geological structure and rich mineral resources. The reserves of gold, coal and copper mines are among the top in the world, with high mining value and great development potential. Recently, the Mongolian 2 million TPA gold ore processing plant built by Xinhai was officially put into production. The whole processing plant adopts Xinhai customized "whole mining industry chain service (EPC+M+O)". The successful operation of the project further expands the brand influence of Xinhai in Mongolia, and consolidates the development road of Xinhai in the Mongolian mining market.

The Mongolian gold ore processing plant project client was introduced and consulted Xinhai for the general contracting service of the concentrator, and needed to provide gold smelting construction engineering design, including: processing technology, civil engineering major, electric power major, water supply and drainage major, heating major, etc. After detailed communication, the customer learned about Xinhai high-efficiency and low-consumption analytical electrolysis system, affirmed the advantages of Xinhai, and successfully reached a cooperation agreement with Xinhai to help its gold ore processing plant project construction.

01 Gold ore processing capacity: 2 million TPA

02 Gold ore processing flow: heap leaching - activated carbon adsorption - desorption electrolysis - activated carbon pickling and regeneration - smelting

03 Gold ore processing equipment: carbon adsorption column, desorption electrolysis system, pickling agitation tank, activated carbon regeneration furnace, high-frequency gold melting furnace

Xinhai customizes the design plan for each mine, and adopts the customized mode from comprehensive on-site inspection, determination of feasible plan to the preparation of construction drawings of the ore processing plant. Combined with the overall situation of the gold mine project, Xinhai Mining Design Institute has carried out a full range of gold smelting construction engineering design for the mine after many on-site inspections, including technology majors, civil engineering majors, electric power majors, water supply and drainage majors, heating majors, etc. professional design.

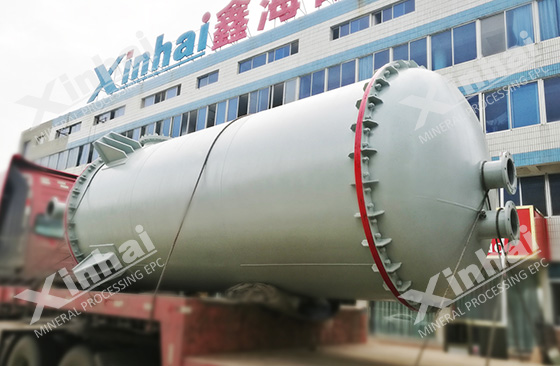

The Mechanical Design and Research Institute under Xinhai can customize gold ore dressing equipment for customers according to the needs of the project design plan. Xinhai mechanical designers have carried out technical transformations on common mining equipment to reduce equipment energy consumption as much as possible, improve efficiency, and at the same time improve the quality of concentrate recovery to ensure project investment returns.

Xinhai has an experienced installation and commissioning team and a perfect packaging and shipping management system. Under the influence of the COVID-19, the installation and commissioning team of Xinhai overcame the difficulties and arrived at the gold mine project site as soon as possible to participate in, manage the equipment installation and commissioning of the project, and provide it with professional maintenance and training services.

From mine design, equipment manufacturing and procurement, packaging and shipping, to installation and commissioning, worker training, and reaching the standard and production capacity, Xinhai is contracted as a whole, providing one-stop, customized solutions for processing plants. The entire gold mine processing plant project has high construction efficiency, short construction period and quick production.

Xinhai has designed a gold ore heap leaching process for this concentrator, which is simple in process and low in investment cost. In order to achieve the project target of the dressing plant, Xinhai Mining Machinery Design Institute has made corresponding technical improvements for the actual production of the dressing plant, so that the entire project can run efficiently and stably.

The design of the dressing plant refers to the terrain construction, and the equipment configuration of the dressing plant considers the realization of self-flow. The operation of similar equipment is relatively centralized configuration, which is convenient for operation and management. The building materials of the concentrator are flexibly assembled, disassembled and moved according to the space design and unloading design to achieve rapid construction and efficient plant construction.

The successful operation of the Mongolian 2 million TPA gold ore processing plant project is the full recognition of Xinhai professional strength from customers. At the same time, this is another successful case of Xinhai "Mining Whole Industry Chain Service (EPC+M+O)". Xinhai has always adhered to the service concept of "what you need is what we can do", providing customized mining services for each processing plant project, helping global customers to build modern, efficient and high-quality processing plant projects and realizing mineral processing. The rational use of resources adds strength to the modern development of the mining industry.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.