Carbonaceous gold ore is a kind of difficult-to-select gold ore. Since easy-to-select high-grade gold ores have become increasingly scarce, this kind of difficult-to-select gold has become the development target of major investors. There are many methods for beneficiating carbon-containing gold ore, and the specific process depends on the properties of the ore. This article takes a certain carbonaceous gold ore as an example to introduce its flotation process.

The ore is an altered silicified breccia gold ore. The main gold-bearing minerals in the ore are carbonaceous materials, with a gold-in-carbon distribution rate of 57%; other minerals account for 43% of the gold-bearing minerals. The gold in the ore is extremely fine-grained and often symbiotic with other minerals. The main metal minerals are gold and silver minerals, accompanied by mercury, antimony, etc., and a small amount of arsenic; the gangue minerals are mainly quartz, followed by calcite, mica, etc. This carbonaceous gold ore has a high carbon content and is the main carrier of gold.

Since the ore contains high carbon content and is the main carrier mineral of gold, combined with the analysis of multiple mineral processing tests, it was finally determined to adopt the process flow of preferential carbon flotation-tailings gold flotation.

The carbon in this gold ore is brittle and easily muddied, and is the main carrier mineral for gold. During the flotation process, carbon will adsorb a large amount of flotation reagents, resulting in excessive reagent consumption. Regardless of the amount of collector used, the gold recovery rate and concentrate grade are not high. Therefore, priority flotation method must be used to remove carbon first.

The process is: due to the brittleness of carbon, before flotation, in order to reduce excessive wear and achieve the separation effect, a period of conventional grinding can be used. The suitable fine particles are -200 mesh accounting for 55%, and carbon flotation is preferred. When using kerosene and No. 2 oil, the dosage of kerosene is 70g/t. After one rough selection, one selection and one sweep, carbon can be effectively removed.

The tailings after carbon flotation are flotated for gold. The process is that the tailings are finely ground in two stages until -200 mesh accounts for 80%. After a rough separation, a fine selection, and a sweep process, the gold separation is completed. During the process, since most of the carriers of gold are carbonaceous substances, followed by sulfides, CuSO4 is used to activate them, which is helpful for the recovery of gold. Moreover, the gold embedded in this ore has a fine particle size. Grinding requires the ore to reach a certain fineness to dissociate the gold mineral monomer. Therefore, the collector No. 38 xanthate dosage is 200g/t and butylammonium blackate 80g/t. , lime slurrying, pH=7 to complete flotation, and finally obtain a concentrate with a gold grade of 28.80g/t, and a gold recovery rate of 41.22%.

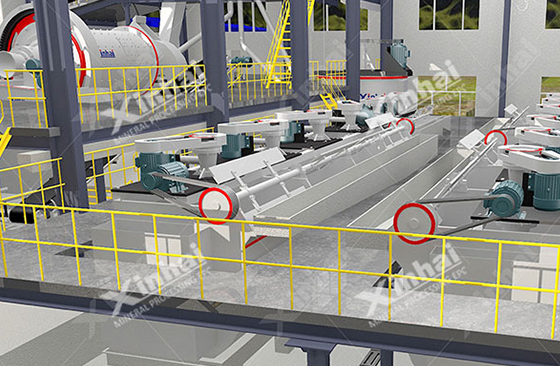

The above is an introduction to the flotation process of a certain carbonaceous gold ore. In the actual gold beneficiation process, the customization of the gold ore beneficiation process plan and the selection of chemicals must meet the characteristics of the ore in order to effectively obtain high-grade gold concentrate. Therefore , it is recommended to conduct a mineral processing test first, and design a suitable gold mine mineral processing process through test analysis. At the same time, a complete set of gold mine mineral processing equipment can also be designed according to the gold mine process. If necessary, please feel free to consult Xinhai Mining, which can provide gold mines processing and mining industry chain services.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.