Alluvial gold mine is a clay sediment mineral containing gold formed by long-term weathering of vein gold deposit. It is a mineral with industrial mining value. In this paper, we will take you to understand alluvial gold processing method from the main characteristics, ore processing preparation work and separation stage.

This type of gold deposit can be subdivided into shore gold deposits, river valley gold deposits, river beach gold deposits, and riverbed gold deposits. The gold content fluctuates greatly, ranging from tens of milligrams per cubic meter to dozens of kilograms per cubic meter. In the deposits of sedimentary gold deposits, due to the elutriation during the formation process, the useful minerals with large specific gravity are relatively concentrated. In addition to natural gold, useful minerals usually include platinum, cassiterite, magnetite, ilmenite, chromite, rutile, wolframite, scheelite, rare earth and other minerals. Gangue minerals usually include quartz, garnet, tourmaline, barite, mica, etc. Among them, the particle size of natural gold is usually between 0.1 mm and 4 mm, and the shape is various.

According to the different mud content, it can also be divided into easy-washable type with mud content less than 10%, medium washable type with mud content between 10-15%, hard-to-wash type with mud content between 15-30%, and difficult-to-wash type with mud content greater than 30%. Fine mud is mainly composed of non-metallic minerals, including kaolin, colloidal hydromica, calcite, feldspar and other fine mud minerals. The particle size is usually greater than 5 microns, and the content is more than 3%.

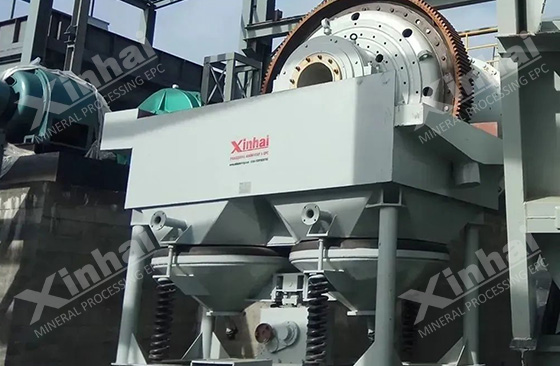

The beneficiation preparation of alluvial gold ore mainly includes wet crushing, ore washing and wet screening of placer gold. In this process, large-grained gangue and fine mud can be discarded, which is convenient for subsequent classifying and gravity separation to recover gold.

At this stage, factors that can affect the efficiency of preparation work include the elutriation degree of the raw ore, the particle size composition of the raw ore, the water supply method, the amount of water supply, the type of crushing equipment, the residence time of the raw ore in the crushing equipment, crushing and washing, mine strength etc.

In the sorting stage, alluvial gold mines usually use gravity separation to recover gold, and sometimes a combined process of gravity separation and amalgamation is used. According to the different equipment used, it can be divided into chute separation process, jigging separation process, shaking table separation process, etc.

As a relatively simple gravity separation equipment, chute separation has the characteristics of large processing capacity, high enrichment ratio, and wide separation particle size range. The main influencing factors include the processing capacity of 1 meter long chute width or 1 square meter collection area, chute inclination, slurry concentration, slurry flow rate, covering material and shape, particle size composition of raw ore, heavy sand content, washing times, etc.

Jig separation process has certain requirements on gold particles and content. It is usually used for raw ore with a particle size of less than 0.2mm, accounting for 10-15%, and a gold content of 25-300 mg per cubic meter. It can recover granular gold below 0.2 mm. Compared with chute and jigging separation process, it has a higher gold recovery rate.

The processing capacity of shaker separation is relatively small, but the obtained concentrate has a high enrichment ratio. Shaker separation can be divided into two types: coarse sand shaker separation and slime shaker separation. The recovery rate of sorting coarse particles is high, up to 98%~99%, and the recovery rate of gold ore from sorting slime is only between 35%~55%, which is mainly used for fined separation process.

The above is about the alluvial gold processing technology. In the actual production, it should determine the specific mineral processing technology and equipment through the beneficiation test result. On the basis of guarantee indicators, it can get great economic benefit.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.